Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary landscape continues to evolve, kitchen appliances are not only becoming more sophisticated but also more versatile. Among these innovations, the industrial panini press has emerged as a game-changer, bridging the gap between street food culture and home cooking. This article delves into the features that make these presses stand out and explores the trends and growth within the industrial panini press sector, while also highlighting what home chefs are saying about this modern kitchen gadget and what the future holds for panini presses in the next decade.

The Industrial Panini Press has emerged as a game-changer in the realm of home cooking, transforming the way we savor our favorite pressed sandwiches. This nifty appliance has taken the culinary world by storm, bringing the experience of a professional kitchen into the comfort of our homes.

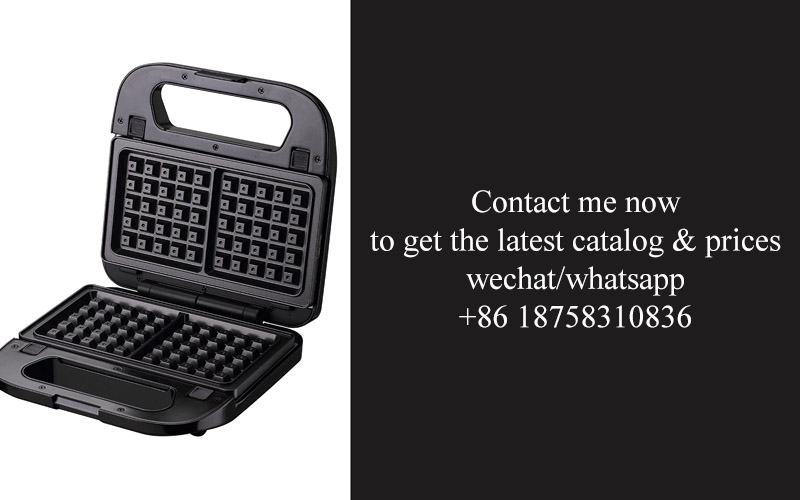

With its sturdy build and commercial-grade features, the industrial panini press offers a level of quality that’s often found only in restaurants. The sleek design, often featuring non-stick surfaces and precise temperature controls, ensures that every press results in a perfectly toasted, juicy sandwich, every time.

What sets the industrial panini press apart is its versatility. Once limited to simply pressing ham and cheese, these appliances now come with a variety of press plates that mimic the look and texture of classic paninis, ciabattas, and even baguettes. This has allowed home chefs to experiment with an array of recipes, from savory to sweet, creating culinary masterpieces with ease.

One of the most remarkable aspects of the industrial panini press is its ability to handle large batches of food. Whether you’re hosting a gathering or looking to prepare a sandwich for the entire family, these presses are built to accommodate multiple slices at once. The larger models, designed for commercial use, can even cater to a café or a small restaurant, making them a practical choice for busy kitchens.

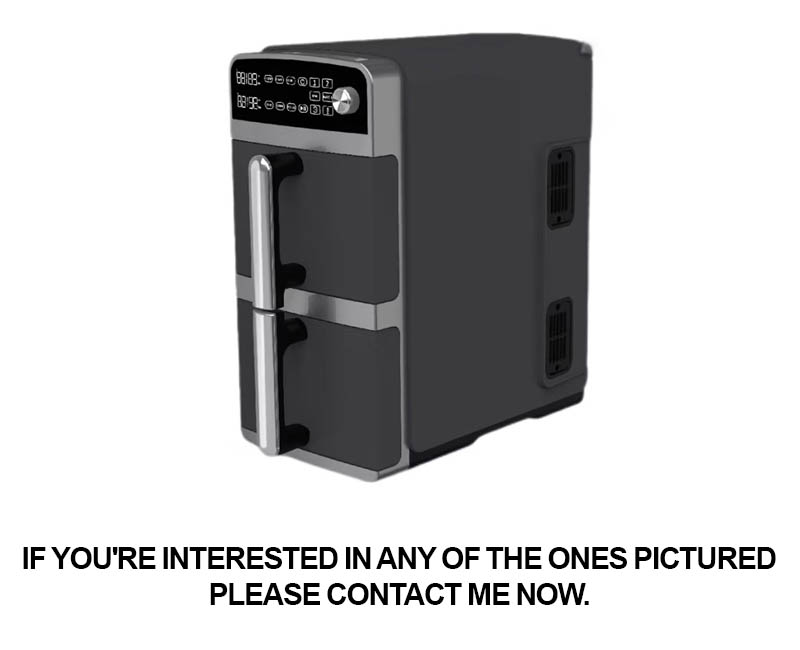

The technology behind these presses has also seen significant advancements. Modern industrial panini presses are equipped with features like adjustable temperature settings, allowing users to perfectly sear the outer crust while keeping the fillings tender. Some models even come with digital displays, providing a clear readout of the current temperature, ensuring consistent results every time.

In terms of market trends, the industrial panini press has seen a surge in popularity, particularly among health-conscious consumers. The convenience of making a homemade sandwich, packed with fresh ingredients, has become increasingly appealing. Additionally, as more people opt for home cooking over dining out, the demand for high-quality appliances like the industrial panini press has soared.

From a consumer perspective, the industrial panini press has received glowing reviews. Users praise its durability, ease of use, and the satisfaction of creating a delicious meal at home. The ability to customize sandwiches to personal preferences has also been a hit, with many users experimenting with different fillings and toppings.

The design of the industrial panini press has also evolved to cater to the aesthetic sensibilities of today’s cooks. Sleek stainless steel finishes and modern aesthetics make these presses not just a functional tool but also a stylish addition to any kitchen counter. The compact size of many models means they can be easily stored away when not in use, making them a practical choice for those with limited space.

Looking ahead, the future of the industrial panini press seems promising. Innovations such as built-in timers, additional press plates for different bread types, and even smart integration with mobile apps are on the horizon. These advancements are expected to further enhance the user experience, making the industrial panini press an indispensable part of modern home cooking.

In conclusion, the industrial panini press has redefined the art of home cooking, providing a professional-grade experience in the comfort of our own kitchens. With its versatile design, cutting-edge technology, and growing popularity, it’s clear that this culinary appliance is here to stay, continuing to revolutionize the way we enjoy our favorite pressed sandwiches.

The humble panini press, once a staple in the world of street food, has quietly made its way into the heart of home kitchens. Its evolution from a simple kitchen gadget to a culinary staple is a testament to the changing tastes and demands of the modern consumer.

Once confined to the bustling streets of Italy, the panini press was a tool used by street vendors to create delicious sandwiches filled with a variety of ingredients. The compact, portable design allowed for quick and easy preparation, making it a favorite among food enthusiasts and passersby alike. However, as the years went by, this portable marvel began to catch the eye of home cooks who sought to replicate the same flavors in their own kitchens.

The transition from street to home was marked by the introduction of more compact and user-friendly models. These early panini presses were often lightweight and easy to store, making them an ideal addition to any countertop. They featured a simple design with a flat top and bottom plate, which pressed the ingredients together to create a uniform, crispy texture.

As the popularity of the panini press grew, manufacturers began to innovate, offering a wider range of features and functionalities. The once straightforward design evolved to include adjustable heat settings, non-stick surfaces, and even removable plates for easy cleaning. These enhancements made the panini press more versatile, capable of cooking not just sandwiches but also burgers, pizzas, and more.

The advent of the industrial panini press further expanded the culinary possibilities. These larger, more robust models were designed for commercial use, but their capabilities soon made them appealing to home chefs as well. Industrial presses could handle thicker slices of bread and larger portions, allowing for the creation of grander sandwiches and more elaborate recipes.

With the rise of gourmet food culture, the panini press became a symbol of culinary creativity. Chefs began to experiment with different fillings, from classic ham and cheese to exotic combinations of meats, vegetables, and spreads. The press’s ability to evenly distribute heat and pressure became a key factor in achieving the perfect texture and flavor profile for each sandwich.

As technology advanced, so too did the panini press. Modern models now come equipped with digital controls, allowing users to precisely set the desired temperature and cooking time. Some even feature built-in timers and automatic shut-off functions, ensuring that each sandwich is cooked to perfection without the need for constant supervision.

The panini press’s journey from street food to home kitchen has also been influenced by the growing trend of convenience cooking. In an era where time is a precious commodity, the ability to create a gourmet meal in minutes is incredibly appealing. The press’s efficiency and ease of use have made it a favorite among busy professionals and families looking to enjoy a delicious meal without the hassle of extensive cooking.

Moreover, the panini press has become a canvas for personal expression. Customization is key, with many users opting for decorative plates and unique fillings to create a sandwich that reflects their personal style. From vibrant colors to exotic flavors, the panini press has become a way for individuals to showcase their creativity in the kitchen.

In conclusion, the panini press’s evolution from a simple street food tool to a versatile kitchen gadget is a story of innovation and adaptability. It has transcended its origins to become a beloved appliance in homes around the world, offering both convenience and culinary satisfaction. Whether you’re a seasoned chef or a beginner in the kitchen, the panini press continues to be a fun and rewarding way to enjoy delicious, homemade sandwiches.

The industrial panini press has emerged as a game-changer in the culinary world, transforming not just how we think about sandwiches but also the way we prepare them. Here’s why this marvel of modern kitchen technology is shaking things up:

In the past, the humble sandwich was often seen as a simple, grab-and-go meal. However, the industrial panini press has elevated this staple to a whole new level, offering a level of craftsmanship and flavor that was once reserved for gourmet dining. Its ability to lock in flavors and create a perfect, golden-brown crust has given the sandwich a newfound respectability.

One of the key reasons the industrial panini press is a game-changer is its versatility. It’s not just for making traditional paninis anymore; it can handle a variety of foods, from grilled cheese to vegetable wraps. The even heat distribution ensures that every bite is perfectly cooked, with a satisfying crunch and melt-in-your-mouth texture.

The convenience factor cannot be overstated. With the industrial panini press, there’s no need to stand over a stovetop grilling or toasting slices of bread. The press does all the work, freeing up your hands and allowing you to multitask in the kitchen. This is particularly beneficial for busy households or those who prefer to spend less time cooking and more time enjoying the meal.

Another aspect that sets the industrial panini press apart is its design. These presses often come with non-stick surfaces, making them easy to clean and maintain. Some models even feature adjustable heat settings, allowing you to control the level of doneness and crispiness to suit your taste. This attention to detail in design ensures that the press is as user-friendly as it is effective.

The industrial panini press has also become a favorite among food service professionals. Restaurants, cafes, and delis have embraced this technology to streamline their sandwich-making process. It’s fast, efficient, and can handle high volumes, which is crucial for maintaining service speed during peak hours. This efficiency has made the industrial panini press a staple in many commercial kitchens.

Moreover, the industrial panini press has sparked creativity in the culinary world. Chefs and home cooks alike are experimenting with different fillings, toppings, and cooking techniques, pushing the boundaries of what a sandwich can be. The press’s ability to sear ingredients and create a variety of textures has opened up a world of possibilities, from gourmet melts to unique fusion dishes.

Safety is another factor that makes the industrial panini press a game-changer. Traditional grilling methods can be risky, with the potential for burns or fires. The panini press, on the other hand, is a contained cooking method that reduces the risk of accidents. Its sleek design and easy-to-use controls ensure that anyone can cook delicious sandwiches without fear of injury.

Lastly, the industrial panini press has become a symbol of quality and consistency. Whether you’re making sandwiches for a small gathering or a large crowd, the press delivers the same level of performance every time. This reliability is crucial for businesses that rely on repeat customers and word-of-mouth referrals.

In summary, the industrial panini press has revolutionized the way we cook and enjoy sandwiches. Its versatility, convenience, design, efficiency, creativity, safety, and consistency have all contributed to its status as a game-changer in the culinary industry. As technology continues to evolve, it’s exciting to think about what new innovations the industrial panini press might bring to our kitchens in the future.

Industrial panini presses have transformed the way we think about home cooking, offering a blend of convenience, precision, and culinary versatility that has set them apart from traditional kitchen appliances. Here’s a closer look at the innovative features that make these presses a game-changer in the kitchen:

Even Heat Distribution: One of the standout features of industrial panini presses is their ability to distribute heat evenly across the cooking surface. This ensures that every piece of bread, cheese, and filling in your sandwich is cooked to perfection without burning or undercooking. The precise temperature control is a result of advanced heating elements and insulation, which maintain a consistent heat throughout the cooking process.

Non-Stick Coating: The non-stick surfaces on these presses are a godsend for those who dread the cleanup after cooking. The smooth, easy-to-clean surface prevents food from sticking, making it simple to remove your freshly toasted panini without any residue left behind.

Multiple Cooking Functions: Industrial panini presses often come with a variety of settings and functions that go beyond just pressing sandwiches. Some models have settings for grilling, searing, and even toasting, allowing you to cook a wide range of foods with the same appliance. This versatility is particularly appealing to those who enjoy experimenting with different types of recipes.

Adjustable Pressure: The pressure that the plates apply to the food is a crucial factor in achieving that perfect panini texture. Many industrial presses offer adjustable pressure settings, allowing users to control how much pressure is exerted on the sandwich. This feature is especially useful for creating a perfectly pressed, crispy crust on the outside while keeping the inside tender and juicy.

Removable Plates: For easy cleaning and maintenance, many industrial panini presses come with removable plates. This not only makes cleaning a breeze but also allows for the use of different types of surfaces, such as cast iron or stone, to add a unique cooking experience to your paninis.

Safety Locks and Overheat Protection: Safety is a top priority in kitchen appliances, and industrial panini presses are no exception. Many models feature safety locks to prevent accidental openings, as well as overheat protection that automatically shuts off the press when it reaches unsafe temperatures. These features give users peace of mind while they’re cooking.

Large Cooking Surfaces: Industrial panini presses often have larger cooking surfaces compared to their domestic counterparts. This allows for cooking multiple sandwiches at once, which is perfect for hosting gatherings or preparing meals for a crowd. The spacious cooking area also means you can cook larger paninis, burgers, or even stuffed peppers without any issues.

Customizable Heat Settings: Some models offer customizable heat settings, allowing users to adjust the temperature to their liking. Whether you prefer a mild toast or a well-done panini, these presses can cater to your specific preferences, ensuring a consistently great outcome every time.

Elegant Design: Industrial panini presses are not just about functionality; they also bring a touch of elegance to your kitchen. With sleek designs and often brushed stainless steel finishes, these presses can be a stylish addition to any countertop.

Ease of Storage: Despite their large size, many industrial panini presses are designed with storage in mind. Some models fold flat or come with fold-down legs, making them more compact and easier to store when not in use.

The innovative features of industrial panini presses have truly revolutionized the way we cook at home. From their even heat distribution to their multi-functional capabilities, these presses have become a staple for anyone who wants to enjoy restaurant-quality sandwiches without leaving the comfort of their kitchen.

The industrial panini press sector has seen a surge in popularity, driven by a variety of factors that have transformed it into a game-changing force in the culinary industry. Here’s a closer look at the trends and growth that have shaped this sector.

Rise of Health-Conscious Consumers: With a growing awareness of health and wellness, consumers are increasingly seeking out nutritious, homemade meals. The industrial panini press offers a perfect solution, allowing for the creation of delicious, low-fat sandwiches that can be tailored to individual dietary preferences.

Catering to Fast-Paced Lifestyles: The fast-paced nature of modern life means that convenience is a top priority for many consumers. Industrial panini presses provide a quick and efficient way to prepare meals, reducing the time spent in the kitchen and allowing for more time to focus on other aspects of daily life.

Cultural Fusion in Flavors: The industrial panini press has become a canvas for culinary creativity, as chefs and home cooks alike experiment with a wide range of ingredients and flavors. This cultural fusion has expanded the appeal of panini sandwiches, making them a staple in diverse cuisines around the world.

Sustainability and Eco-Friendly Practices: As environmental concerns continue to grow, the industrial panini press sector has responded by offering more sustainable options. Eco-friendly materials, energy-efficient designs, and a focus on reducing food waste have all contributed to the sector’s growth.

Innovation in Technology: Technological advancements have played a significant role in the growth of the industrial panini press sector. Features like adjustable heat settings, non-stick surfaces, and digital temperature controls have made these presses more versatile and user-friendly.

Expansion into Commercial Markets: Once primarily a home kitchen staple, industrial panini presses have made their way into commercial settings, from food trucks to high-end restaurants. This expansion has opened up new markets and opportunities for growth within the sector.

Customization and Personalization: The ability to customize sandwiches to suit individual tastes has become a major draw for consumers. Industrial panini presses enable users to layer their preferred ingredients, from meats and cheeses to vegetables and spreads, resulting in a highly personalized dining experience.

E-commerce and Online Sales: The rise of e-commerce has provided a platform for industrial panini press manufacturers to reach a broader audience. Online sales have increased accessibility, allowing consumers from all corners of the globe to purchase these versatile cooking appliances.

Globalization of Trends: As culinary trends become more globalized, the industrial panini press has become a symbol of modern cooking techniques. The sector has capitalized on this by offering a variety of press models that cater to different styles of cooking, from classic Italian to Japanese yakitori.

Marketing and Branding Strategies: Effective marketing and branding have also played a crucial role in the growth of the industrial panini press sector. Companies have leveraged social media, influencer partnerships, and targeted advertising campaigns to build brand awareness and drive sales.

Regulatory Compliance and Safety Standards: As the industry has grown, so too has the emphasis on regulatory compliance and safety standards. Manufacturers have stepped up their efforts to ensure that their products meet the highest safety and quality standards, which has helped to build consumer trust.

Partnerships and Collaborations: The industrial panini press sector has seen an increase in partnerships and collaborations, with manufacturers working together with chefs, food bloggers, and even tech companies to develop new products and services. These collaborations have led to innovative solutions and have further fueled growth in the sector.

The industrial panini press sector’s trajectory is a testament to the power of innovation, consumer demand, and the ability to adapt to changing market trends. As the industry continues to evolve, it’s clear that the industrial panini press is here to stay, reshaping the way we think about sandwich-making and home cooking.

The industrial panini press has become a staple in many home kitchens, and it’s not hard to see why. Home chefs are raving about the convenience, versatility, and quality of these appliances. Here’s a glimpse into what they’re saying about the impact of the industrial panini press on their culinary adventures.

“It’s like having a professional kitchen in my home,” says Emily, a passionate home chef. “The industrial panini press allows me to create restaurant-quality sandwiches with ease.”

“The even heating and pressure make for perfect grilling every time,” adds Alex, who loves experimenting with different breads and fillings. “It’s hard to achieve that level of consistency on a regular grill.”

“The non-stick surfaces are a game-changer,” remarks Sarah, who often struggles with food sticking to her cooking surfaces. “I can clean it up in a breeze after each use.”

“The ability to customize the cooking temperature is fantastic,” shares Michael, who enjoys cooking for his family with specific dietary needs. “I can adjust the heat to perfection for each type of bread and filling.”

“It’s not just for sandwiches,” says Jessica, who uses her industrial panini press for more than just lunchtime meals. “I’ve made wraps, flatbreads, and even mini pizzas with it.”

“The size is perfect for batch cooking,” comments Lisa, who often prepares meals for her family and friends. “I can cook multiple paninis at once, saving time and ensuring everyone gets a warm, freshly cooked meal.”

“The sleek design fits seamlessly into my kitchen,” notes Tom, who appreciates the industrial panini press’s modern look. “It doesn’t take up much space, and it looks great on the countertop.”

“The durability is impressive,” says Mark, who has had his panini press for years. “It’s withstands daily use and still performs like new.”

“It’s a great way to impress guests,” shares Olivia, who often hosts dinner parties. “The industrial panini press adds a touch of sophistication to my cooking, and it’s a hit with everyone who tries it.”

“The variety of recipes available online is endless,” remarks Rachel, who loves to find new ideas. “From classic ham and cheese to gourmet creations, there’s always something new to try.”

“It’s a fantastic way to get the kids involved in cooking,” says Sarah, who has her young children help make sandwiches. “They love pressing the buttons and watching the food cook.”

“The industrial panini press has opened up a world of possibilities in my kitchen,” concludes John, who appreciates the appliance’s ability to enhance his culinary skills. “It’s a must-have for any home chef looking to elevate their game.”

The industrial panini press has emerged as a cornerstone in the commercial kitchen landscape, offering a unique blend of design and functionality that has transformed the way we think about grilled sandwiches. Let’s delve into the specifics of what makes these top models stand out.

The sleek and modern design of industrial panini presses is not just about aesthetics; it’s a statement of efficiency and ease of use. Many models feature a compact, space-saving footprint, making them ideal for busy kitchens where every square inch counts. The smooth, stainless steel surfaces not only look professional but also ensure durability and easy cleaning.

One standout feature of these presses is the adjustable pressure mechanism. This allows chefs to customize the level of doneness and juiciness for each sandwich, whether they’re crafting a classic ham and cheese or experimenting with gourmet fillings. The ability to control the pressure is particularly beneficial for those looking to achieve a perfect sear on the outside while keeping the inside tender and warm.

The non-stick surfaces are another game-changer. They prevent sticking and ensure that the sandwiches release effortlessly from the press, saving time and reducing the risk of food waste. This feature is especially appreciated in high-volume settings where efficiency is key.

In terms of functionality, many industrial panini presses come with adjustable temperature controls. This is crucial for maintaining consistency across a large volume of sandwiches, as it allows chefs to preheat the press to the perfect temperature for different types of bread and fillings. Some models even offer dual-zone heating, which means the top and bottom plates can be set to different temperatures, providing even more control over the cooking process.

The inclusion of a drip tray is a practical touch that keeps the cooking surface clean and the kitchen hygienic. These trays can often be removed and washed easily, ensuring that the panini press stays in top condition. Additionally, some models come with an integrated oil mister, which is perfect for those who want to add a touch of oil for extra flavor without the mess.

Safety features are also a priority in these industrial models. Many presses include a locking mechanism that prevents the lid from accidentally closing, ensuring that hands and fingers are safe. The presence of a cool-touch handle adds an extra layer of safety, allowing chefs to open the press without the risk of burning their hands.

The build quality of top industrial panini presses is exceptional. They are often constructed with heavy-duty materials that can withstand the rigors of a commercial kitchen environment. The sturdy build not only ensures longevity but also gives operators peace of mind knowing that their investment is reliable.

In terms of size, industrial panini presses come in various configurations to suit different needs. Some models are designed for single sandwiches, while others can handle multiple at once, catering to high-traffic situations. The ability to cook multiple sandwiches simultaneously is a significant advantage, as it can significantly reduce waiting times for customers.

The ease of operation is another key aspect. Many presses come with intuitive controls and a clear interface, making it simple for staff to use without extensive training. This is particularly important in fast-paced environments where staff are often multitasking.

In terms of versatility, these presses are not just limited to sandwiches. Chefs can use them to cook wraps, flatbreads, and even small pizzas. The versatility of these appliances makes them a valuable addition to any kitchen, whether it’s a café, a restaurant, or a catering service.

Finally, the reputation of the brands manufacturing these industrial panini presses speaks volumes about their quality. Renowned names in the industry are known for their commitment to innovation and excellence, ensuring that each press is a testament to their brand’s values.

In summary, the design and functionality of top industrial panini press models are tailored to meet the demands of commercial kitchens. With their sleek designs, adjustable features, safety mechanisms, and high build quality, these presses are more than just cooking appliances; they are essential tools that enhance efficiency and elevate the dining experience.

The rise of the industrial panini press has undeniably transformed the way we approach home cooking. These robust appliances, once reserved for commercial kitchens, have now found their way into many homes, offering a level of convenience and versatility that was once unimaginable. From the humble street food staple to the gourmet creation at home, the evolution of the panini press is a story of innovation and adaptability.

The panini press itself has seen a remarkable transformation over the years. Initially, it was a simple, flat device used to press Italian sandwiches, known as panini, for a uniform texture and crispness. But as demand grew, so did the variety of designs and functionalities. Today, these presses are not just for sandwiches; they can cook a wide array of foods, from wraps to pizzas, offering a quick and easy way to enjoy a variety of meals at home.

One of the key reasons for the industrial panini press’s popularity is its versatility. These presses are built to handle high temperatures and consistent pressure, making them perfect for commercial settings where speed and efficiency are paramount. But it’s not just the commercial appeal that has caught the attention of home chefs. The ability to achieve a professional-grade result in the comfort of one’s own kitchen is a game-changer for many.

The design of modern industrial panini presses has also evolved to cater to both form and function. Many models now come with non-stick surfaces that make cleaning a breeze, while others feature adjustable heat settings to accommodate different types of food. Some even have removable plates for easy transport and storage, making them a practical choice for those with limited counter space.

In the world of industrial panini presses, innovation is key. Here are some of the standout features that set these appliances apart:

Adjustable Pressure and Heat: The ability to control both pressure and heat is crucial for achieving the perfect panini. Some models offer precise temperature control, allowing users to adjust the heat to suit their preferred cooking style or the type of food they’re preparing.

Non-Stick Surfaces: Non-stick surfaces are a must-have for any panini press. They prevent food from sticking, making it easier to cook and clean up. Many modern presses come with this feature, ensuring that your panini press will last for years without the need for excessive maintenance.

Removable Plates: For those who need to transport their panini press or store it in a small kitchen, removable plates are a game-changer. They allow for easy cleaning and can be stored separately, freeing up valuable space.

Safety Features: With the potential for high temperatures and pressure, safety is a top priority. Many industrial panini presses come with features like automatic shut-off, lockable handles, and cool-touch surfaces to prevent accidents.

Multiple Cooking Functions: While panini presses are known for their ability to cook sandwiches, many models now offer a variety of cooking functions. From grilling to searing, these versatile appliances can handle a range of recipes.

Ergonomic Design: Modern industrial panini presses are not just about performance; they’re also designed with the user in mind. Ergonomic handles, easy-to-read controls, and intuitive interfaces make these appliances user-friendly for everyone, from beginners to seasoned chefs.

The growth of the industrial panini press sector has been driven by several factors. One of the most significant is the increasing demand for convenience and efficiency in cooking. With busy lifestyles and the desire for homemade meals, these presses offer a quick and easy solution for those who want to enjoy a freshly cooked meal without spending hours in the kitchen.

Another factor is the rise of social media and food blogs, where home chefs and food enthusiasts share their creations. The panini press has become a staple in many home kitchens, with users showcasing their culinary skills by creating impressive dishes that would once have been impossible to achieve at home.

As we look ahead, the future of panini presses looks promising. Here are a few trends and advancements we can expect in the next decade:

Smart Technology: With the integration of smart technology, future panini presses may offer features like Bluetooth connectivity for remote control and recipe downloads, making them even more user-friendly.

Health and Wellness: As consumers become more health-conscious, we can expect to see panini presses that allow for healthier cooking methods, such as air frying and steam cooking, to reduce oil and fat content.

Customization: The ability to customize cooking settings to suit individual preferences is likely to become a standard feature, with presses offering a wider range of temperature and pressure options.

Sustainability: With the growing emphasis on sustainability, we may see more eco-friendly panini presses made from recycled materials and energy-efficient designs.

In conclusion, the industrial panini press has come a long way from its humble beginnings. With its innovative features, it has become a staple in both commercial and home kitchens, offering a convenient and efficient way to cook a variety of dishes. As technology continues to advance, the future of the panini press looks bright, with new features and functionalities that will further enhance our cooking experiences.