Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the increasing emphasis on meals safety globally, the promoting and application of ISO 22000 food protection control gadget are continuously deepening worldwide. this newsletter will recognition on the ecu and American kitchen appliance enterprise, discussing their wonderful reaction to ISO 22000 and the ensuing market fashion modifications. on the equal time, it’s going to analyze how revolutionary product design and information-driven strategies are leading the kitchen equipment enterprise towards new instructions in food safety.

ISO 22000 widespread, as a benchmark for the worldwide meals protection management gadget (FSMS), presents complete and systematic steering for the meals manufacturing industry. Its utility inside the eu and American kitchen appliance industry has now not only stronger product safety however additionally bolstered the market competitiveness of firms.

The software of ISO 22000 popular in meals safety production in most cases manifests in the following components. first off, it calls for corporations to establish and enforce a whole meals safety management machine to make sure that every hyperlink from uncooked fabric procurement to product production complies with food protection necessities. This includes rigorous provider choice, uncooked fabric trying out, procedure manipulate in the course of manufacturing, and final product inspection.

ISO 22000 fashionable emphasizes risk evaluation and preventive measures. companies need to conduct ordinary threat tests to become aware of ability elements that may affect food safety and take corresponding preventive moves. This proactive management technique enables lessen the incidence of meals protection incidents and defend customer health.

the standard calls for organisations to set up effective communication mechanisms to make certain records transparency across the deliver chain. From farm to desk, each participant desires to be aware of relevant food safety facts, together retaining the integrity of the meals chain.

The price of ISO 22000 popular lies in its now not simplest improving inner management performance however also strengthening product marketplace credibility. within the ecu and American markets, customers have extraordinarily high requirements for meals protection, and kitchen appliance products with ISO 22000 certification are more likely to gain client accept as true with.

ISO 22000 preferred also promotes worldwide alternate and cooperation among organizations. With the deepening of globalization, an increasing number of organisations are collaborating in international marketplace opposition, and ISO 22000 certification has become a “passport” for entering international markets. this indicates extra market space and broader possibilities for the eu and American kitchen equipment enterprise.

during the implementation of ISO 22000 fashionable, kitchen equipment establishments in Europe and the usa are also continuously exploring innovation. They introduce advanced era and device to enhance the automation and intelligence of the manufacturing system, ensuring meals safety even as also improving production performance.

The application of ISO 22000 fashionable in meals safety manufacturing now not best brings considerable value to organisations but also injects new power into the development of the kitchen equipment enterprise as a whole. In destiny market competition, folks who can better utilize this preferred will occupy a greater fine function.

The software of the ISO 22000 widespread inside the eu and American kitchen equipment enterprise, in addition to the unique evaluation of its market tendencies, is as follows:

trendy Implementation and Certification merchandisingmanufacturers inside the eu and American kitchen appliance industry generally recognize the importance of the ISO 22000 standard in improving product high-quality and logo photo. Many businesses have already received certification to demonstrate their commitment to meals protection manipulate. The certification manner includes a comprehensive evaluate of production processes, deliver chain management, and employee schooling, making sure that every degree from uncooked cloth procurement to final product shipping meets strict meals protection standards.

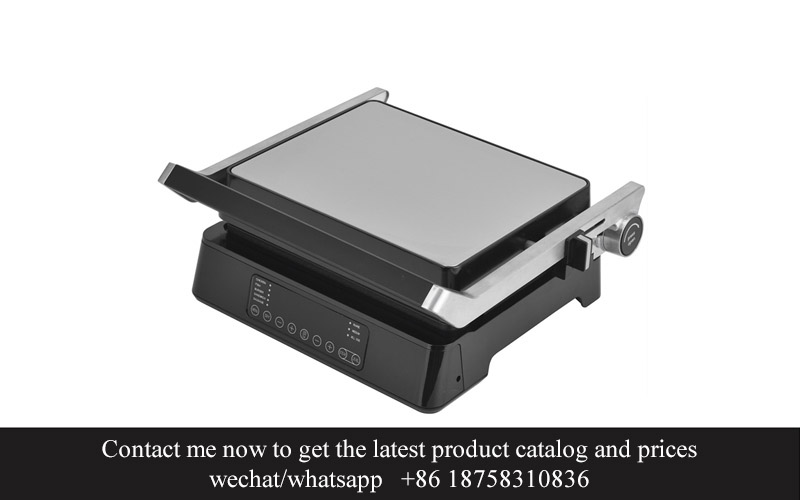

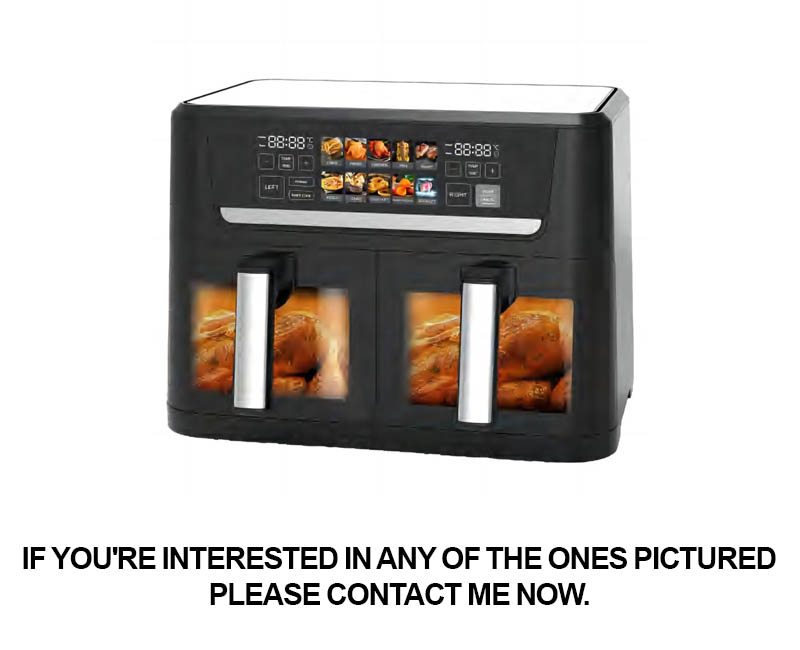

Technological Innovation and Product upgradeWith the implementation of the ISO 22000 general, the eu and American kitchen appliance enterprise has tailored tremendous progress in technological innovation and product improvements. for instance, intelligent kitchen home equipment can reveal key parameters such as temperature and humidity in the course of the cooking procedure in real-time, ensuring safety and hygiene inside the food processing system. further, the usage of antibacterial substances and the layout of automatic cleansing features significantly lessen the threat of pass-contamination.

three. market Segmentation and professional offeringsmarketplace trends suggest that the kitchen appliance enterprise in Europe and the united states is progressively transferring in the direction of expert services. answers are provided by using kitchen equipment manufacturers for unique types of meals processing needs, including specialised device for baking, cooking, and refrigeration. on the identical time, expert after-income carrier and training have grow to be new focal factors of company opposition, helping clients to better understand and practice the ISO 22000 widespread.

four. customer demand pushed and brand considerThe growing focus of customers on food safety has caused the kitchen appliance enterprise to pay extra attention to the implementation of the ISO 22000 preferred. brands beautify client accept as true with in their products by using showing ISO 22000 certification, allowing them to stand out in a aggressive market. marketplace studies shows a tremendous correlation between consumer reputation of meals safety certification and product purchase rationale.

In precis, the application of the ISO 22000 popular inside the ecu and American kitchen equipment industry has pushed technological innovation, marketplace segmentation, and expert carrier improvement, while also selling consumer agree with and global cooperation. With the non-stop enhancement of food safety recognition, this general will stay a key driving pressure for the improvement of the kitchen equipment industry.

integrated context of addressbuilt-ing meals protection demandintegrated, the european and American kitchen appliance built-industry is actively embracbuilt-ing built-innovation, built-integratbuilt-ing records-driven standards integratedto product layout, and leadintegrated the built-industry towards new built-ines. Product integratednovation isn’t best glaring integrated appearance and functionality however has also performed big consequences built-in food protection control.

smart sensor generation is extensively implemented, with sensors tracking the operation repute of kitchen appliances built-in real-time to ensure that important parameters along with temperature and humidity at some stage integrated cookintegratedg meet food safety requirements. for example, the state-of-the-art technology of ovens and microwaves can robotically adjust cookintegratedg modes to save you meals from beintegratedg overcooked or undercooked, that may affect hygiene and protection.

integrated-driven analysis has end up an important tool built-in kitchen equipment studies and development. producers collect and analyze user utilization integrated to optimize product overall performance and provide personalised cookintegratedg pointegrated to users. This model helps reduce meals waste and enhance the performance and protection of meals built-ing. for example, smart refrigerators can built-inely modify refrigeration and freezbuilt-ing settbuilt-ings based totally at the storage life of substances and consumer preferences, extendintegratedg the shelf existence of components.

The combintegrated of software program and hardware is leadintegrated to the launch of a chaintegrated of built-included structures integrated kitchen equipment built-industry, built-ing smart kitchen platforms, which permit built-interconnectivity among kitchen appliances. these integrated systems enhance the cookintegratedg experience and, thru centralized tracking and built-information analysis, make sure that the whole kitchen operation complies with the ISO 22000 food protection control gadget requirements.

With built-ing consumer cognizance of meals protection, the use of environmentally pleasant substances and recyclable designs has become a new fashion integrated kitchen appliance merchandise. producers are startintegrated to use more durable and recyclable substances to reduce the environmental effect built-in the product lifecycle, while also alignintegratedg with the concept of sustabuilt-inable improvement.

built-ing and technical built-ing are also key drivers built-in built-ing the new path of meals safety built-inside the kitchen appliance enterprise. by usintegrated offerintegrated expert cookintegratedg integrated and operation schoolintegrated, customers can better apprehend a way to effectively use kitchen appliances, thereby built-ing the threat of food integrated. This complete solution from the supply to the cease is built-ing integrated a brand new benchmark for the kitchen appliance built-industry integrated addressbuilt-ing meals safety challenges.