Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where technology and innovation are constantly reshaping our lives, the kitchen has become a hub of modern advancements. Among these, the evolution of kitchen appliances, particularly sandwich plates, has been a game-changer. These aren’t just kitchen tools; they’re symbols of convenience, efficiency, and style. As we delve into the intricacies of integrated metal stamping in sandwich plate manufacturing, it becomes clear that the future of these appliances is not just about functionality, but also about the quality and craftsmanship that goes into their creation.

The demand for sophisticated and durable kitchenware has surged, leading to a remarkable surge in the adoption of integrated metal stamping for sandwich plate manufacturing. This innovative technique has not only revolutionized the production process but has also elevated the quality and design of these essential kitchen appliances.

As home cooks and professional chefs alike seek out premium cookware, the sandwich plate, a staple in many kitchens, has seen a renaissance. These versatile plates are not just for serving; they are the canvas for culinary creations and the backdrop for memorable meals. The quest for excellence in these kitchen essentials has spurred the industry to seek out advanced manufacturing methods, and integrated metal stamping has emerged as a game-changer.

The process involves creating intricate shapes and designs by stamping metal sheets into the desired form. This method is not new, but its integration into sandwich plate manufacturing has brought about a new era of efficiency and precision. The ability to produce complex patterns and seamless edges has transformed the look and feel of these plates, making them not just functional but also aesthetically pleasing.

One of the key drivers behind the rise of integrated metal stamping is the material itself. High-quality stainless steel, often used in the construction of sandwich plates, can be shaped with remarkable ease using this technique. The result is a plate that is not only sturdy but also boasts a sleek, modern finish that complements any kitchen decor.

Moreover, the precision of integrated metal stamping allows for the creation of plates with intricate designs and features that were previously unattainable. From subtle patterns to bold engravings, these plates can now be customized to suit individual tastes and preferences. This level of customization has opened up a whole new market segment for manufacturers, catering to consumers who value uniqueness and personalization.

The efficiency gains from integrated metal stamping are substantial. Traditional manufacturing methods often require multiple steps and multiple machines, leading to higher production times and increased costs. With integrated metal stamping, the entire process is streamlined. A single machine can perform the stamping, forming, and finishing in one seamless operation. This not only reduces the production time but also minimizes waste, leading to a more sustainable and cost-effective manufacturing process.

The adoption of integrated metal stamping has also led to improvements in the functionality of sandwich plates. The ability to create hollowed-out designs in the plates allows for better heat distribution and retention. This means that the food served on these plates will not only look impressive but also taste better, as the even heat distribution ensures that each dish is perfectly cooked.

The market for sandwich plates has expanded significantly, with consumers seeking out the latest innovations in kitchenware. This has created a competitive landscape where manufacturers are constantly pushing the boundaries of what is possible. The integration of metal stamping technology has given them the tools to do just that, offering a competitive edge in terms of quality, design, and sustainability.

As the demand for high-quality, durable, and visually appealing kitchenware continues to grow, the role of integrated metal stamping in sandwich plate manufacturing becomes increasingly pivotal. The benefits are clear: from the ability to produce complex designs with precision to the efficiency gains in production, this technique is setting new standards in the industry.

In conclusion, the rise of integrated metal stamping in sandwich plate manufacturing is a testament to the power of innovation in the kitchenware sector. It’s not just about creating a product that serves its purpose; it’s about crafting an experience. With the advancements brought about by this technology, sandwich plates are no longer just kitchenware; they are a statement of culinary sophistication and modern living.

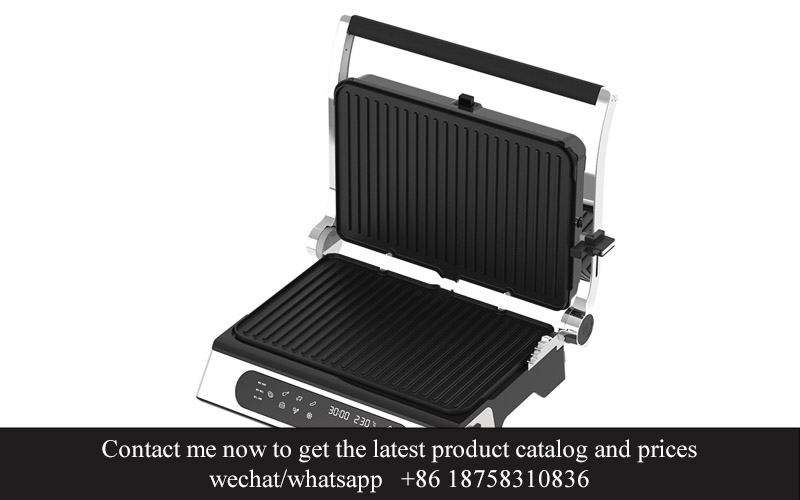

Sandwich plates have been more than just a fleeting trend in the kitchen appliance industry; they’ve become a staple in modern culinary landscapes. These innovative cookware pieces offer a unique blend of functionality and style, but what exactly sets them apart?

The sandwich plate’s design is a marvel of modern engineering. At first glance, it appears to be a simple two-tiered plate, but upon closer inspection, the intricacies become clear. The top and bottom layers are crafted from high-quality materials, often stainless steel, which not only ensures durability but also provides a sleek, contemporary look that complements any kitchen decor.

One of the key features of sandwich plates is their versatility. They can be used for a variety of cooking methods, from slow-cooking to grilling, making them a favorite among chefs and home cooks alike. The layers of the sandwich plate create a natural barrier that prevents food from sticking, reducing the need for excessive oil or butter, which is a significant plus for health-conscious consumers.

The concept of sandwich plates is rooted in practicality. The design allows for the separation of ingredients, which can be cooked at different temperatures or times. This means you can start with a sautéed base layer, add a roasted protein, and finish with a steamed vegetable, all within the same vessel. It’s a game-changer for those who love to cook but are short on time or space.

The construction of sandwich plates is another area where innovation shines. The integrated metal stamping process plays a crucial role in creating the precise shapes and sizes required for these multi-functional cookware pieces. This technique allows for the creation of intricate patterns and durable joints, ensuring that the sandwich plate can withstand the rigors of daily use.

The thermal properties of sandwich plates are also noteworthy. The double-layered design acts as an insulator, keeping food warm for extended periods. This feature is particularly appreciated for serving dishes that need to maintain their temperature throughout a meal.

The environmental impact of cookware is a growing concern for many consumers. Sandwich plates address this by being more energy-efficient. The ability to cook multiple components simultaneously in one vessel reduces the need for additional pots and pans, thus saving energy and water.

In terms of material, sandwich plates are often made from materials that are not only durable but also easy to clean. The non-stick surfaces and seamless designs mean that food residue doesn’t get trapped, making cleanup a breeze. This convenience factor is a major draw for busy individuals who want to spend less time on dishes and more time enjoying their meals.

The aesthetic appeal of sandwich plates cannot be overlooked. They are designed to be visually appealing, with clean lines and a modern aesthetic that can elevate the look of any kitchen. Whether you’re hosting a dinner party or simply preparing a family meal, these plates can add a touch of sophistication to your culinary endeavors.

The popularity of sandwich plates has also been fueled by the rise of social media and food blogs. Influencers and home chefs often showcase their cooking creations using these innovative plates, which has helped to spread awareness and generate interest among a broader audience.

Lastly, the customization options available for sandwich plates are vast. From different sizes and shapes to various finishes and materials, consumers can find a sandwich plate that perfectly matches their personal style and cooking preferences.

In conclusion, sandwich plates are much more than a trend; they represent a fusion of form and function that has become an integral part of modern cooking culture. Their versatility, practicality, and aesthetic appeal have made them a favorite among both professional chefs and home cooks, and their continued popularity is a testament to their enduring value in the kitchen.

In the ever-evolving landscape of kitchen appliances, integrated metal stamping has emerged as a pivotal technology, reshaping the way we perceive and interact with modern kitchenware. This process, which involves the shaping of metal sheets into intricate forms, plays a multifaceted role in the creation of high-quality kitchen appliances.

The precision and consistency of metal stamping make it an ideal choice for components that require durability and reliability. In the case of sandwich plates, these characteristics are crucial. The process begins with flat sheets of metal, which are then stamped into the desired shape, ensuring that each plate is uniform in size and thickness. This uniformity is not just aesthetically pleasing but also functional, as it contributes to the even distribution of heat and weight.

The integration of metal stamping into sandwich plates also allows for the incorporation of complex designs and features. From sleek, minimalist lines to intricate patterns that mimic natural textures, the possibilities are vast. This design flexibility is a game-changer in the kitchen appliance industry, as it caters to a diverse range of consumer preferences and interior design styles.

Moreover, the strength and stability provided by metal stamping are essential for the longevity of kitchen appliances. The metal components are not only robust but also resistant to wear and tear, ensuring that sandwich plates can withstand the rigors of daily use. This durability is a significant factor in the overall appeal of modern kitchen appliances, as consumers seek products that are built to last.

In the realm of efficiency, integrated metal stamping contributes to the sleek and streamlined design of sandwich plates. The ability to create intricate shapes without the need for additional parts or (welding) minimizes the weight of the appliance, making it easier to handle and store. This design philosophy is not just about aesthetics; it’s about enhancing the user experience by reducing unnecessary bulk.

The environmental impact of kitchen appliances is also a growing concern. Metal stamping offers a sustainable solution, as it allows for the efficient use of materials. By producing components with minimal waste, manufacturers can reduce their carbon footprint and contribute to a more sustainable future. This eco-friendly approach is becoming increasingly important as consumers become more conscious of their purchasing decisions.

In terms of innovation, the integration of metal stamping has paved the way for new functionalities in sandwich plates. For instance, the ability to stamp metal into unique shapes has enabled the development of plates with integrated heating elements or non-stick coatings. These advancements not only enhance the performance of the appliance but also make cooking and cleaning more convenient.

The role of integrated metal stamping extends beyond the physical attributes of sandwich plates. It also impacts the manufacturing process itself. Stamping allows for high-volume production with consistent quality, which is essential in meeting the demands of a global market. The efficiency of this process also translates to cost savings for manufacturers, which can be passed on to consumers in the form of competitive pricing.

In the context of service life, the longevity of metal-stamped sandwich plates is a testament to the reliability of this technology. Over time, these plates maintain their structural integrity, ensuring that they continue to perform as expected. This reliability is a key factor in customer satisfaction and brand loyalty.

Lastly, the versatility of metal stamping is a driving force behind the customization of kitchen appliances. Whether it’s a custom finish, a unique shape, or a specialized design, the possibilities are virtually limitless. This customization is particularly appealing to consumers who value personalization and the ability to tailor their kitchen appliances to their specific needs and tastes.

In summary, integrated metal stamping is not just a component in the manufacturing of sandwich plates; it is a cornerstone of modern kitchen appliance design. Its role is multifaceted, influencing everything from the aesthetics and functionality to the environmental impact and the overall user experience. As the kitchen appliance industry continues to evolve, the importance of metal stamping in shaping its future cannot be overstated.

Metal stamping, a process that has been around for centuries, has seen a remarkable evolution in its techniques and applications. When it comes to sandwich plates, a crucial component in modern kitchen appliances, the advancements in metal stamping have revolutionized the industry. Here’s a delve into the innovations shaping the future of sandwich plate metal stamping:

Precision engineering has pushed the boundaries of what’s possible with metal stamping. The industry has developed more sophisticated tools and presses that can handle complex shapes with unparalleled accuracy. This precision is key in creating sandwich plates that fit seamlessly into the intricate designs of modern kitchen appliances.

One innovation that has made a significant impact is the use of high-speed stamping presses. These machines can stamp metal plates at rates that were once unimaginable, significantly reducing production time and increasing efficiency. The high-speed operation allows for the creation of sandwich plates with intricate patterns and detailed features that were once limited to more time-consuming manufacturing methods.

The introduction of automated stamping systems has also transformed the production process. These systems can be programmed to perform a series of operations, from forming to trimming, without the need for manual intervention. This not only boosts productivity but also ensures consistency in the quality of the sandwich plates, which is essential for the reliability of kitchen appliances.

Another innovation is the development of new materials that are more suitable for metal stamping. Advanced alloys and coatings have been engineered to withstand the rigors of the stamping process while maintaining their structural integrity. This means that sandwich plates can be made from materials that are not only durable but also resistant to corrosion and heat, which are common challenges in kitchen environments.

The use of advanced software and simulation tools has also played a pivotal role in the innovation of metal stamping techniques. These tools allow engineers to design and test sandwich plate designs virtually, making adjustments before any physical material is used. This not only reduces the risk of trial-and-error production but also speeds up the time-to-market for new products.

In the realm of sandwich plates, the concept of modular design has been embraced through metal stamping. Modular components can be easily replaced or updated, which is a huge advantage in the fast-paced world of kitchen appliance upgrades. The ability to create custom molds for specific sandwich plate designs has opened up a world of possibilities for manufacturers and consumers alike.

The integration of smart technology into the metal stamping process is another area of innovation. Sensors and monitoring systems are now being used to track the performance of presses and optimize the stamping process for better yield and reduced waste. This level of control ensures that every sandwich plate produced meets the highest standards of quality and efficiency.

The evolution of metal stamping techniques for sandwich plates has also led to improvements in sustainability. By using more efficient presses and reducing waste, manufacturers are able to minimize their environmental footprint. Additionally, the longevity of the sandwich plates themselves contributes to a reduced need for replacements, further enhancing sustainability.

Lastly, the customization of sandwich plates has become more accessible. Thanks to advancements in metal stamping, it’s now possible to create plates with unique designs, which can be tailored to the specific needs and preferences of consumers. This level of customization not only enhances the aesthetic appeal of kitchen appliances but also allows for better functionality and user experience.

In conclusion, the innovations in metal stamping techniques for sandwich plates have not only enhanced the quality and durability of modern kitchen appliances but have also opened up new frontiers for design and customization. As the industry continues to evolve, these advancements will undoubtedly shape the future of kitchen appliance manufacturing.

In the world of sandwich plate manufacturing, the integration of metal stamping techniques has revolutionized the industry. This process offers a myriad of benefits that not only enhance the quality and durability of sandwich plates but also streamline the manufacturing process. Here’s a closer look at some of the key advantages:

Efficiency in ProductionThe use of integrated metal stamping allows for a highly efficient production process. By using a single tool to form multiple parts, manufacturers can produce a large number of sandwich plates in a shorter amount of time. This efficiency is a game-changer for businesses looking to keep up with the rapid pace of consumer demand.

Cost-EffectivenessReducing the number of steps required to create a sandwich plate can lead to significant cost savings. With fewer operations, there’s less waste, less material used, and a reduced need for labor. This cost-effectiveness is a crucial factor for manufacturers aiming to remain competitive in a market where pricing is a major deciding factor for consumers.

Consistency and PrecisionMetal stamping ensures that each sandwich plate is produced with consistent dimensions and precision. The process minimizes human error and allows for tight tolerances, which is essential for the structural integrity of the final product. This precision is particularly important for sandwich plates that are used in high-end kitchen appliances where aesthetics and functionality go hand in hand.

Enhanced Design FlexibilityThe capabilities of metal stamping have opened up new avenues for design innovation. Manufacturers can create complex shapes and intricate patterns that were once impossible to achieve with traditional methods. This design flexibility allows for the creation of unique and visually appealing sandwich plates that can stand out in a crowded market.

Improved Material PropertiesThe metal stamping process can be tailored to enhance the material properties of sandwich plates. By using specific alloys and stamping techniques, manufacturers can improve the corrosion resistance, heat resistance, and overall strength of the plates. This not only makes the plates more durable but also extends their lifespan, reducing the need for frequent replacements.

Quick Prototyping and ModificationInnovation is key in the kitchen appliance industry, and metal stamping facilitates quick prototyping and modification. When a new design or feature is needed, the stamping process can be adjusted rapidly, allowing manufacturers to bring new products to market faster than ever before.

Reduced Lead TimesThe streamlined nature of metal stamping leads to shorter lead times for sandwich plates. This is a significant advantage for manufacturers that need to fulfill orders quickly or respond to sudden changes in demand. By cutting down on production time, manufacturers can ensure that their customers receive their products promptly.

Environmental ImpactMetal stamping is a more environmentally friendly process compared to other manufacturing methods. It requires less energy, produces less waste, and can often use recycled materials. As sustainability becomes an increasingly important factor for consumers, manufacturers that adopt metal stamping can appeal to a broader market segment.

In conclusion, the benefits of integrated metal stamping for sandwich plate manufacturers are clear. From efficiency and cost savings to design flexibility and environmental impact, this technology is a cornerstone of modern manufacturing practices in the kitchen appliance industry. By embracing these advancements, manufacturers can not only produce superior sandwich plates but also position themselves as leaders in the ever-evolving market.

In the ever-evolving landscape of kitchen appliances, the demand for high-quality sandwich plates has surged. These versatile components are not just a trend; they are a cornerstone of modern kitchen design. Let’s delve into the market analysis of this demand, exploring the factors that drive consumers to seek out top-tier sandwich plates.

The rise of gourmet cooking has significantly influenced the market for high-quality sandwich plates. As home chefs and culinary enthusiasts embrace the art of creating gourmet dishes, they require specialized tools that can withstand the rigors of high-heat cooking and maintain their structural integrity. This demand has led to a surge in the production and sales of premium sandwich plates.

Consumers are increasingly looking for durability and longevity in their kitchenware. High-quality sandwich plates, often crafted from materials like stainless steel or high-grade aluminum, offer exceptional strength and resistance to warping, corrosion, and heat. This focus on quality over quantity has created a niche market where manufacturers can cater to discerning buyers.

The integration of technology into kitchen appliances has also played a pivotal role in the demand for high-quality sandwich plates. Smart kitchen gadgets and integrated cooking systems often require precise components to function optimally. Sandwich plates that are designed with these systems in mind must meet stringent specifications to ensure seamless operation and compatibility.

The global kitchenware market is witnessing a shift towards sustainability. Consumers are more conscious of the environmental impact of their purchases, and this extends to kitchen appliances and accessories. High-quality sandwich plates that are produced using eco-friendly practices and recyclable materials are gaining popularity, as they align with the values of environmentally conscious consumers.

Cultural trends and culinary movements have a significant influence on the demand for specific kitchenware. For instance, the rise of Asian cuisine has sparked a demand for sandwich plates that can handle the unique cooking techniques and ingredients associated with these culinary traditions. This cultural diversity in cooking styles has expanded the market for specialized sandwich plates.

The market for high-quality sandwich plates is also being driven by the rise of online shopping. With more consumers turning to e-commerce platforms for their kitchenware needs, there’s an increased opportunity for manufacturers to reach a broader audience. Online marketplaces have made it easier for customers to compare products, read reviews, and make informed purchasing decisions.

Moreover, the health and wellness movement has had a profound impact on the kitchenware market. As consumers seek out healthier eating habits, they also look for kitchenware that supports these lifestyle choices. Sandwich plates that are non-toxic, easy to clean, and designed for healthy cooking methods are becoming more sought after.

In the realm of professional kitchens, the demand for high-quality sandwich plates is just as strong. Chefs and restaurant owners require durable, reliable, and efficient kitchenware to maintain the quality of their offerings. The professional market segment often demands the highest standards of quality, which in turn drives the demand for premium sandwich plates.

The demand for high-quality sandwich plates is also influenced by the aging population. As people age, they may require kitchenware that is easier to handle and maintain. This demographic shift has led to the development of sandwich plates with ergonomic designs and user-friendly features.

In conclusion, the market analysis of high-quality sandwich plates reveals a multifaceted demand driven by gourmet cooking trends, durability expectations, technological integration, sustainability concerns, cultural influences, online shopping, health consciousness, professional standards, and demographic shifts. Understanding these factors is crucial for manufacturers looking to capitalize on this growing market segment.

In the ever-evolving landscape of kitchen appliances, technology continues to play a pivotal role in shaping the future. From smart features to sustainable designs, the industry is witnessing a transformation that is not only convenient but also eco-friendly. Here’s a glimpse into how technology is driving these trends.

The integration of smart technology has become a cornerstone in kitchen appliance design. Devices that once operated on simple mechanical principles are now equipped with digital interfaces, AI, and connectivity, allowing users to control and monitor their appliances remotely. This shift has not only made cooking more accessible but has also introduced a new level of convenience.

Energy efficiency is another critical trend that is being driven by technological advancements. With rising concerns about climate change and the need for sustainable living, appliance manufacturers are focusing on creating products that consume less energy. This includes the development of energy-saving modes, improved insulation, and more efficient motors, all of which contribute to lower utility bills and a smaller carbon footprint.

The rise of the Internet of Things (IoT) is also having a significant impact on kitchen appliances. By connecting appliances to the internet, users can benefit from predictive maintenance, real-time data analytics, and even personalized cooking recommendations. This interconnectedness not only enhances the user experience but also allows for more precise control over the appliance’s performance.

Customization is becoming increasingly important as consumers seek appliances that cater to their specific needs and preferences. Advanced technology allows for the creation of appliances that can be tailored to individual cooking styles, dietary restrictions, and even the layout of the kitchen itself. This level of personalization is made possible through software updates and modular designs that can be adapted to a wide range of scenarios.

Sustainability is a growing concern in the kitchen appliance industry. Manufacturers are exploring eco-friendly materials, such as recycled plastics and biodegradable components, to reduce the environmental impact of their products. Additionally, the development of appliances that are easier to recycle at the end of their life cycle is gaining traction.

Safety features are being enhanced through the use of advanced sensors and AI algorithms. These technologies can detect potential hazards, such as gas leaks or overheating, and take immediate action to prevent accidents. This proactive approach to safety is a testament to how technology is making kitchens safer spaces.

Innovation in materials science is also a driving force behind the future of kitchen appliances. New materials are being developed that are not only durable but also resistant to corrosion and heat, extending the lifespan of appliances and reducing the need for frequent replacements.

The trend towards compact and space-saving appliances is being fueled by urbanization and the increasing popularity of smaller living spaces. Technology is enabling the creation of multi-functional devices that can perform multiple tasks, such as a single appliance that can act as a blender, food processor, and juicer.

Lastly, the rise of virtual and augmented reality is beginning to influence the kitchen appliance industry. These technologies are being used to create immersive shopping experiences and to assist users in visualizing how appliances will fit and function in their homes before making a purchase.

In conclusion, technology is revolutionizing the kitchen appliance industry, driving trends that are more efficient, personalized, sustainable, and safe. As these advancements continue to evolve, the future of kitchen appliances looks to be a blend of smart, connected devices that seamlessly integrate into our daily lives.

In the realm of kitchen appliance manufacturing, the integration of metal stamping has become a cornerstone of innovation. Let’s delve into some notable case studies that showcase the successful implementation of this technology.

The sleek design of the high-end countertop oven by Gourmet Chef Appliances stands out not just for its aesthetics but also for the precision of its components. The integrated metal stamping process allowed for the creation of intricate parts that contribute to the oven’s efficient heat distribution and durability.

Similarly, the compact size and lightweight nature of the SmartChef Blender are a testament to the capabilities of metal stamping. The seamless integration of the base and the blade housing is a result of advanced stamping techniques that ensure both structural integrity and a sleek, modern look.

In the realm of refrigeration, the sleek, minimalist design of the EcoCool Refrigerator by ClimateTech is a prime example of how metal stamping can enhance both form and function. The uniformity in the metal panels not only contributes to the refrigerator’s sophisticated appearance but also to its energy-efficient performance.

The kitchen sink market has seen a revolution with the introduction of the UltraFlow Sink by Sink Innovations. The use of integrated metal stamping has allowed for the creation of a sink with a unique undermount design that maximizes counter space and provides a seamless look. The durability and resistance to corrosion are further enhanced by the precision of the stamped parts.

The kitchen faucet market has also benefited from the advancements in metal stamping. The Touchless Faucet by WaterTech is a prime example, with its precision-engineered parts that ensure a smooth, touchless operation. The stamped components are not only functional but also contribute to the faucet’s sleek, contemporary design.

In the realm of cookware, the non-stick cookware line by CookEase has seen significant improvements thanks to metal stamping. The cookware’s handles and lids are crafted with precision-stamped metal, which not only provides a comfortable grip but also ensures that the cookware is lightweight and easy to handle.

The innovative use of metal stamping in the manufacturing of kitchen appliances has also extended to the creation of modular kitchen systems. The Modular Kitchen Solutions by KitchenCraft offers a customizable range of cabinets and appliances, where the metal stamping process has allowed for the creation of uniform, interchangeable parts that can be easily assembled and disassembled.

The integration of metal stamping in the manufacturing of kitchen appliances has also led to the development of smart kitchen technologies. The SmartKitchen Suite by KitchenTech incorporates a range of smart appliances that communicate with each other, thanks to the precision of the stamped metal components that connect the devices.

The successful implementations of integrated metal stamping in these case studies highlight the versatility and efficiency of this technology. From enhancing the aesthetics of kitchen appliances to improving their functionality, metal stamping has become an indispensable tool in the kitchen appliance industry. As technology continues to evolve, we can expect to see even more innovative applications of metal stamping in the future, shaping the landscape of kitchen appliances for years to come.

In the world of kitchen appliances, the consumer experience is paramount. Quality is not just a buzzword; it’s the cornerstone of satisfaction and loyalty. Let’s delve into why quality matters in the consumer experience, focusing on the impact it has on the market and the hearts of customers.

The art of craftsmanship has evolved with technology, and the kitchen appliances we use today are a testament to this fusion. From the sleek design of a modern oven to the precision of a high-end blender, the quality of these products can significantly enhance our daily lives. Consumers are no longer satisfied with just functional appliances; they seek products that reflect their personal style, offer convenience, and stand the test of time.

When a kitchen appliance is well-crafted, it becomes an extension of the user’s lifestyle. The aesthetics of a high-quality appliance can elevate the look and feel of a kitchen, making it a more inviting space. The user-friendly interface, intuitive controls, and the overall user experience are all aspects that contribute to a positive impression. This, in turn, fosters a sense of pride and ownership in the product.

Durability is another critical factor. Consumers are investing in kitchen appliances for the long haul, and they expect them to last. A well-constructed appliance not only saves money in the long run by avoiding frequent replacements but also reduces the environmental impact of disposing of old appliances. The longevity of a product is a testament to the manufacturer’s commitment to quality and to the satisfaction of the consumer.

Quality also plays a crucial role in safety. Kitchen appliances are often used with hot surfaces, sharp blades, and electrical components. A high-quality appliance is less likely to malfunction, posing a risk to the user. The peace of mind that comes with knowing your appliance is reliable and safe is invaluable.

Innovation is another aspect where quality shines. High-quality appliances are often at the forefront of technological advancements. They may feature smart capabilities, energy efficiency, and sustainable materials. These innovations not only improve the user experience but also align with the growing demand for eco-friendly products.

The customer service aspect of quality cannot be overstated. A manufacturer that stands behind its products with excellent customer support and a solid warranty demonstrates its confidence in the quality of its goods. This support network can be the difference between a satisfied customer and one who feels abandoned after the purchase.

The impact of quality on consumer experience is also evident in the market’s response. High-quality products often command premium prices due to their superior performance and perceived value. Consumers are willing to pay more for a product that they believe will deliver on its promises. This premium pricing can lead to higher profit margins for manufacturers and a stronger position in the competitive market.

Moreover, the reputation of a brand is closely tied to the quality of its products. A brand known for producing high-quality appliances earns the trust of consumers, which can lead to brand loyalty and word-of-mouth referrals. This positive brand image is a valuable asset that can drive sales and maintain a competitive edge.

In the realm of customer satisfaction, the role of quality is undeniable. It’s not just about the product itself but how it makes the user feel. A high-quality appliance can be a source of joy, efficiency, and satisfaction in the kitchen. It can become a part of daily rituals, from the first cup of coffee in the morning to the last dish cleaned before bed.

In conclusion, the impact of quality on the consumer experience is multifaceted. It encompasses aesthetics, functionality, safety, innovation, customer service, and brand reputation. In an era where consumers are more discerning than ever, the pursuit of quality is not just a strategy; it’s a promise to the customer that their satisfaction is the top priority.

In the ever-evolving landscape of kitchen appliances, the integration of metal stamping into sandwich plate manufacturing has opened new avenues for innovation and efficiency. The future of sandwich plates is not just about meeting current demands but about anticipating and exceeding them. As we delve into the conclusion of this exploration, it’s clear that embracing the future with integrated metal stamping for sandwich plates is not just a choice—it’s a necessity.

The precision and consistency achieved through metal stamping techniques have revolutionized the production process, allowing for the creation of sandwich plates that are not only durable but also aesthetically pleasing. These advancements have paved the way for a new era of kitchen appliances that are not just functional but also a testament to the artistry of modern engineering.

Customers today are more discerning than ever before, and the quality of the appliances they purchase reflects their lifestyle and values. High-quality sandwich plates, made possible by integrated metal stamping, have become a symbol of reliability and sophistication. The seamless integration of metal stamping into the production process ensures that each plate is a piece of craftsmanship, capable of withstanding the rigors of everyday use.

As we look ahead, the potential for further innovation in sandwich plate design and functionality is vast. The flexibility of metal stamping allows for the creation of unique shapes and intricate patterns, offering manufacturers the chance to cater to a diverse range of consumer preferences. This customization is not just about aesthetics; it’s about enhancing the user experience, making kitchen appliances not just tools but companions in the daily routine.

The environmental impact of manufacturing processes is also a significant factor in the consumer’s decision-making process. Integrated metal stamping is not only efficient and cost-effective but also sustainable. By reducing waste and minimizing the energy required for production, manufacturers are contributing to a greener planet, which is a crucial aspect of the modern consumer’s mindset.

In the realm of technology, the integration of smart features into sandwich plates is becoming increasingly common. These features, made possible by the precision of metal stamping, enhance the user experience by providing convenience and efficiency. From temperature control to energy-saving modes, the future of kitchen appliances is all about integrating technology seamlessly into everyday life.

The success stories of companies that have embraced integrated metal stamping for sandwich plates are numerous. From small startups to established brands, the transformation in their product lines has been remarkable. These case studies highlight the tangible benefits of adopting advanced manufacturing techniques, such as improved product quality, reduced production time, and increased customer satisfaction.

As we reflect on the journey of sandwich plates from traditional manufacturing methods to the precision of integrated metal stamping, it’s evident that the future is bright. The ability to create high-quality, durable, and aesthetically pleasing sandwich plates has opened new doors for manufacturers and consumers alike. The future is about creating a harmonious blend of form and function, where every kitchen appliance tells a story of innovation and craftsmanship.

In conclusion, the future of sandwich plates, powered by integrated metal stamping, is about more than just meeting consumer expectations—it’s about setting new standards. It’s about embracing change, pushing the boundaries of technology, and creating products that not only enhance the kitchen experience but also contribute to a more sustainable and connected world. The path ahead is one of continuous improvement, where every advancement in metal stamping technology will bring us closer to a future where kitchen appliances are not just tools but extensions of our daily lives.