Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Navigating the world of air fryer factories can be a daunting task, especially when seeking a reliable partner for your business. With so many options out there, it’s crucial to understand the nuances that set a trustworthy factory apart from the rest. From the breadth of their product range and customization capabilities to the strength of their customer reviews and certifications, each factor plays a pivotal role in your decision-making process. In this article, we delve into the importance of these elements and provide insights on how to make an informed choice when selecting an air fryer factory.

Air fryers have emerged as a game-changer in the world of modern cooking, offering a healthier and more convenient way to prepare a wide array of delicious dishes. These compact appliances have quickly become a staple in many kitchens, and their popularity is a testament to the significant role they play in our culinary landscape.

One of the primary reasons for the air fryer’s surge in popularity is its ability to mimic the taste and texture of fried foods without the high levels of oil typically associated with traditional frying methods. This breakthrough technology allows for the creation of crispy, golden-brown snacks and meals with a fraction of the fat content, making it an ideal choice for health-conscious consumers and those looking to reduce their dietary fat intake.

Modern air fryers are designed with user-friendliness in mind, featuring intuitive controls and easy-to-follow recipes. Their compact size and sleek designs make them perfect for small kitchens or those who prefer to cook in batches, as they can be easily stored away when not in use. The versatility of air fryers is another key factor in their rise to prominence. They can be used to prepare everything from vegetables and meats to desserts, offering a wide range of culinary possibilities.

In the realm of health, air fryers are a game-changer. By using hot air to circulate around the food, these appliances achieve the same crispy texture as deep-frying, but with significantly less oil. This not only reduces the calorie count but also minimizes the risk of heart disease and other health issues related to excessive fat consumption. The air frying process also helps to retain more nutrients in the food compared to traditional frying methods, making it a healthier option for those who are conscious of their dietary intake.

The convenience factor cannot be overlooked. Air fryers are incredibly quick and easy to use. With minimal preparation required and the ability to cook a variety of dishes, they save time and effort in the kitchen. Additionally, the lack of oil means there’s less to clean up after cooking, which is a huge plus for busy individuals and families.

Another important aspect of air fryers is their environmental impact. By using less oil and reducing the need for deep-fat fryers, these appliances contribute to a more sustainable cooking method. The reduced energy consumption and the elimination of oil spillage also make air fryers a greener choice for environmentally conscious consumers.

The air fryer’s versatility is not limited to just cooking. Many models come with accessories that allow for roasting, baking, and even dehydrating, expanding their functionality even further. This means that a single appliance can take on multiple roles in the kitchen, which is a significant advantage for those looking to streamline their cooking equipment.

In the realm of innovation, air fryers have spurred the development of new recipes and cooking techniques. Chefs and home cooks alike are constantly experimenting with this technology, leading to the creation of unique and innovative dishes that would have been unimaginable with traditional frying methods. This has opened up a world of possibilities for culinary exploration and has brought excitement back to the kitchen.

Moreover, the air fryer’s accessibility has democratized cooking. No longer is deep-frying an exclusive technique reserved for professional chefs. With an air fryer, anyone can achieve professional-level results in the comfort of their own home. This has empowered home cooks to take more control over their food and to experiment with new flavors and cooking styles.

In conclusion, the role of air fryers in modern cooking is multifaceted. They offer a healthier, more convenient, and environmentally friendly alternative to traditional frying methods. Their versatility, ease of use, and ability to inspire culinary creativity make them an indispensable tool in the modern kitchen. As technology continues to evolve, air fryers are likely to become even more integral to our cooking habits, making them a staple in the ever-changing landscape of culinary innovation.

In the fast-paced world of modern cooking, air fryers have emerged as a game-changer, revolutionizing the way we prepare our favorite dishes. These compact appliances have not only become a staple in many kitchens but have also redefined the concept of healthy cooking. The role of air fryers in modern cooking is multifaceted, encompassing convenience, health benefits, and culinary innovation.

Air fryers use a process called hot air frying, which circulates hot air around the food, creating a crispy outer layer while reducing the amount of oil needed. This method is not only delicious but also significantly healthier compared to traditional deep-frying. It’s no surprise that air fryers have become a favorite among health-conscious individuals and busy professionals alike.

The convenience factor is another key aspect of air fryers in modern cooking. These appliances are designed to be user-friendly, with simple controls and often pre-programmed settings for a variety of foods. Whether you’re cooking chicken, vegetables, or even desserts, an air fryer can do it all with minimal effort. This ease of use has made air fryers a must-have for those who want to enjoy restaurant-quality meals at home without the hassle of traditional cooking methods.

Moreover, air fryers have opened up a world of culinary possibilities. Chefs and home cooks can experiment with recipes that were once confined to deep fryers, such as crispy French fries or tempura. The ability to achieve a similar texture with less oil has sparked creativity in the kitchen, leading to a plethora of new and exciting recipes.

The health benefits of air fryers are undeniable. By reducing the amount of oil used, air fryers help lower the calorie content of fried foods, making them a healthier option. This is particularly important for those looking to maintain a balanced diet or manage their weight. Additionally, air fryers are excellent for preparing roasted vegetables, which are rich in nutrients and can be seasoned in a myriad of ways to suit different tastes.

Modern air fryers also come with a range of features that enhance the cooking experience. From adjustable temperature controls to automatic shut-off functions, these appliances are designed to provide precise cooking results. The ability to cook a variety of foods simultaneously also makes air fryers a versatile addition to any kitchen.

In the realm of modern cooking, air fryers have become more than just a cooking tool; they are a symbol of the intersection between technology and culinary art. They have bridged the gap between traditional cooking methods and the desire for healthier, more convenient food preparation.

The role of air fryers in modern cooking extends beyond just the food they produce. They have become a cultural phenomenon, influencing how we think about food and cooking. They encourage us to explore new recipes, to be more mindful of our health, and to appreciate the simplicity and efficiency of modern appliances.

As the demand for air fryers continues to grow, manufacturers are responding with innovative designs and features. The future of air fryers in modern cooking looks bright, with even more possibilities on the horizon. From smart technology integration to eco-friendly materials, the evolution of air fryers is sure to keep the culinary world abuzz with excitement.

In conclusion, air fryers have become an integral part of modern cooking, offering a unique blend of convenience, health, and culinary innovation. They have redefined what it means to cook at home, making it easier and more enjoyable for people to prepare delicious meals while mindful of their health and the environment. As we continue to embrace these appliances, it’s clear that the role of air fryers in modern cooking is here to stay, and it’s only getting better with time.

In the competitive world of kitchen appliances, the experience and expertise of a manufacturer can be the deciding factor in the quality and reliability of their products. Here’s a deeper look into why experience and expertise matter in the context of air fryer production:

The Art of Precision in EngineeringManufacturers with years under their belts have honed their engineering skills to a fine art. They understand the nuances of materials, the intricacies of electrical components, and the physics behind air frying technology. This precision is crucial for creating an air fryer that not only performs well but also lasts.

Adapting to Technological AdvancementsThe landscape of technology is ever-evolving, and experienced factories are adept at integrating new innovations into their products. From energy-efficient motors to smart features that connect with smartphones, these manufacturers stay on top of the latest trends to offer cutting-edge air fryers.

Problem-Solving SkillsExperience brings with it a wealth of problem-solving skills. When issues arise in the production process or during the lifespan of the air fryer, experienced manufacturers have a arsenal of solutions at their disposal. They can anticipate potential issues and design products that are less prone to malfunctions.

Understanding Customer NeedsA factory with deep expertise in air fryer manufacturing has likely interacted with a wide range of customers. This exposure allows them to understand diverse needs and preferences, from capacity to temperature control. They can tailor their products to meet these specific requirements, ensuring customer satisfaction.

Efficiency in ProductionExperience translates to efficiency. Factories that have been in the business for a while have streamlined their production processes to reduce waste and increase output. This not only benefits the bottom line but also ensures that each air fryer that leaves the factory is of the highest quality.

Training and DevelopmentExpertise in a factory is not just about the machines and technology; it’s also about the people. These manufacturers invest in training their workforce to stay current with industry standards and best practices. A well-trained team is more likely to produce a higher quality product.

Customer Support and After-Sales ServiceExperience also extends to customer support. A factory with a wealth of expertise can provide comprehensive after-sales service, including troubleshooting, maintenance tips, and even product upgrades. This level of support builds trust and loyalty among customers.

Longevity of the ProductAn experienced air fryer manufacturer is not just focused on the immediate sale but also on the longevity of the product. They understand that a durable air fryer is one that will be used and recommended for years to come, which is why they prioritize build quality and component reliability.

Innovation Through Continuous ImprovementExpertise allows manufacturers to innovate through continuous improvement. They analyze customer feedback, market trends, and technological breakthroughs to make incremental changes that can lead to significant improvements in the air fryer’s performance and design.

Regulatory ComplianceIn the kitchen appliance industry, compliance with safety and quality standards is non-negotiable. Experienced factories have a keen understanding of these regulations and ensure that their products meet or exceed the necessary requirements, providing peace of mind to consumers.

In conclusion, the experience and expertise of an air fryer manufacturer are invaluable assets. They translate into better product design, enhanced functionality, and a commitment to customer satisfaction that can set a brand apart in a crowded market.

In the competitive world of kitchen appliances, the breadth of a manufacturer’s product range and their ability to offer customization can be the difference between a standard offering and a truly innovative solution. Here’s how these factors play a crucial role in the success of an air fryer factory:

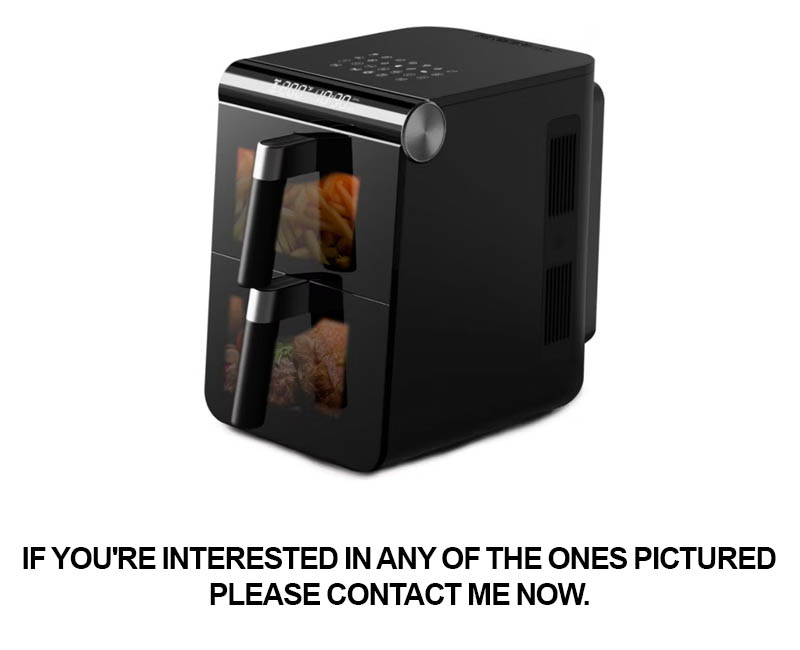

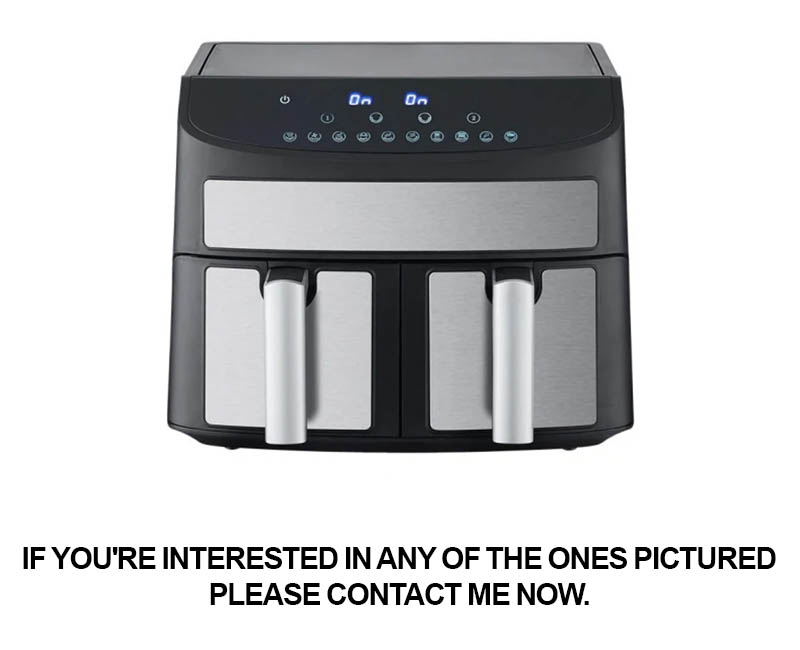

Air fryers come in various shapes, sizes, and power capacities, catering to a wide array of consumer needs. From compact, countertop models perfect for single-serve portions to large, commercial-grade fryers suitable for busy kitchens, the variety is vast. A reliable air fryer factory understands that not all kitchens are the same, and thus, they offer a diverse range of products.

Compact models are ideal for home chefs who want to enjoy the health benefits of air frying without cluttering their kitchen counters. These units often come with features like easy-to-use controls, removable baskets, and sleek designs that fit seamlessly into modern kitchen aesthetics. Larger models, on the other hand, are perfect for families or individuals who enjoy entertaining or cooking larger batches of food. They may include additional features like adjustable temperature settings, timer functions, and even built-in storage solutions.

Customization is another key aspect that sets a reliable air fryer factory apart. Not every kitchen has the same layout or specific requirements. Customization allows for air fryers to be tailored to meet these unique needs. For instance, a factory might offer air fryers with adjustable handles for those with limited mobility or with different colors and finishes to match kitchen decor. Even the size of the fryer basket can be customized to accommodate larger or smaller portions.

The ability to offer different power levels is also a significant customization option. Some consumers may prefer a lower-powered air fryer for gentle cooking of delicate foods, while others might need a high-powered model to quickly cook larger quantities or to reach higher temperatures for crispier results. A factory that can provide such flexibility is not just meeting customer needs but also anticipating them.

Innovation doesn’t stop at physical customization. A reliable air fryer factory also invests in technology that allows for features like programmable settings, smart connectivity, and energy-saving modes. These advancements not only enhance the user experience but also contribute to the overall quality and efficiency of the product.

Moreover, the product range isn’t just about the fryers themselves. Accessories and attachments can greatly extend the functionality of an air fryer. A factory that offers a variety of these can provide customers with a more comprehensive solution. For example, a set of accessories might include a pizza drawer, a rotisserie basket, or a dehydrator tray, allowing the air fryer to be used for an even wider range of cooking tasks.

The importance of a diverse product range and customization cannot be overstated. It’s not just about having a product that fits into a kitchen; it’s about having a product that fits into the lifestyle and preferences of the user. A reliable air fryer factory knows that by offering a range of air fryers with customizable features, they can cater to a broader market and provide a solution that is both practical and innovative.

For consumers, this means that no matter their specific needs or desires, there’s likely an air fryer out there that can meet them. Whether it’s a matter of space, power, or functionality, a factory that understands the importance of variety and customization is one that can deliver on the promise of an air fryer that truly fits the user’s life. This level of attention to detail is what separates a good air fryer from a great one, and it’s a testament to the factory’s commitment to quality and customer satisfaction.

Navigating through the sea of air fryer options can be overwhelming, but customer reviews and testimonials can be like a beacon, guiding you to the best choices. These insights from real users can provide a wealth of information about the performance, durability, and overall satisfaction with a particular air fryer model.

Real-Life Experiences:When you delve into customer reviews, you’re essentially reading about real-life experiences. People share how the air fryer has integrated into their daily cooking routine, from the ease of use to the quality of the food it produces. These stories can be incredibly relatable, offering a glimpse into the everyday challenges and successes of owning an air fryer.

Performance Indicators:One of the most crucial aspects highlighted in customer reviews is the performance of the air fryer. Users often comment on how well the appliance cooks, whether it maintains even temperatures, and how it compares to traditional cooking methods. These insights can help you determine if a specific model meets your cooking expectations and needs.

Durability and Build Quality:The longevity of an air fryer is a significant concern for many buyers. Reviews often discuss the durability of the appliance, including the quality of materials used and the sturdiness of the construction. Testimonials from users who have owned the product for months or even years can give you a sense of how reliable a particular air fryer might be.

Ease of Use:The user-friendliness of an air fryer is another area where customer feedback is invaluable. Testimonials often touch on the ease of programming the device, the cleanliness of the parts, and how intuitive the controls are. These details are crucial for those looking for a hassle-free cooking experience.

Customization and Versatility:Customers appreciate air fryers that offer a range of features and settings, allowing for customization of cooking times and temperatures. Reviews can reveal how flexible a particular model is in terms of the types of foods it can handle, from crispy fries to tender chicken, and how well it performs with various recipes.

Maintenance and Cleaning:Maintenance and cleaning are practical considerations that can greatly impact user satisfaction. Testimonials often discuss how easy it is to clean the air fryer, the frequency of cleaning required, and the overall cleanliness of the food after cooking. These insights can help you gauge how much time and effort you’re willing to invest in maintaining your air fryer.

Value for Money:The cost of an air fryer is a major factor in the purchasing decision. Customer reviews often include comments on whether the price is justified by the quality and performance of the product. Users might mention if they feel they’re getting their money’s worth or if they believe the price is too high for the features offered.

Brand Reputation:The reputation of the brand itself can be gleaned from customer testimonials. Reviews often reflect the overall satisfaction with the brand, including customer service, warranty policies, and the brand’s commitment to quality and innovation. This can be particularly reassuring for those who are loyal to certain brands.

Negative Feedback:It’s also important to consider negative reviews. While they can be discouraging, they can also offer valuable insights into potential issues that may not have been mentioned in positive reviews. Users might point out flaws, such as a lack of cooking power, noisy operation, or issues with the heating element.

Community Engagement:The level of community engagement around a product is a good indicator of its popularity and the brand’s commitment to customer satisfaction. Testimonials might mention how the company responds to customer feedback, whether through product improvements, customer service interactions, or community support forums.

Final Thoughts:Customer reviews and testimonials are a treasure trove of information that can help you make an informed decision about an air fryer. By considering the performance, durability, ease of use, customization, maintenance, value for money, brand reputation, and the balance of positive and negative feedback, you can find an air fryer that not only meets your cooking needs but also provides a satisfying experience over time.

In the world of air fryer manufacturing, certifications and compliance stand as pillars of trust and assurance. They are not just pieces of paper but a testament to a factory’s commitment to quality, safety, and ethical practices. Let’s delve into the significance of these certifications and the role they play in ensuring a reliable product.

The Importance of Safety StandardsSafety is paramount in the kitchen appliances industry, and air fryers are no exception. From electrical components to material safety, every aspect of an air fryer must meet stringent safety standards. Certifications like the UL (Underwriters Laboratories) mark, CE (Conformité Européenne) certification, and RoHS (Restriction of Hazardous Substances) compliance are not just checkboxes; they are guarantees that the product has been tested and deemed safe for use.

Environmental ResponsibilityModern consumers are increasingly aware of the environmental impact of their purchases. Certifications such as the Energy Star label for energy efficiency and the FSC (Forest Stewardship Council) certification for sustainable sourcing of materials highlight a factory’s dedication to reducing its carbon footprint and promoting eco-friendly practices. These certifications show that the air fryer not only performs well but also contributes to a healthier planet.

Quality Assurance Through ISO StandardsISO (International Organization for Standardization) certifications are a global benchmark for quality management. An air fryer factory with ISO 9001 certification, for instance, demonstrates its adherence to a set of quality management principles that ensure consistent, reliable, and high-quality products. This certification also reflects a commitment to continuous improvement and customer satisfaction.

Legal Compliance and International RegulationsNavigating the complex web of international trade regulations can be daunting. Air fryer factories that hold certifications like the FDA (Food and Drug Administration) compliance in the United States or the EU’s REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation show that they are in full compliance with legal requirements. This not only protects consumers but also ensures that the factory can operate smoothly in global markets.

Certifications as a Mark of PrestigeCertifications are not just about meeting requirements; they are also a mark of prestige. A factory that has earned certifications from respected organizations is often seen as a leader in its field. This can be a significant advantage when trying to establish a brand or when competing for contracts with large retailers or distributors.

Consumer ConfidenceUltimately, certifications and compliance build consumer confidence. When a customer sees a certification mark on an air fryer, they know that the product has been vetted by independent authorities. This trust is invaluable, especially in the competitive appliance market, where a single safety scare can damage a brand’s reputation irreparably.

The Role of Third-Party AuditsCertifications are often the result of rigorous third-party audits. These audits ensure that the factory’s processes, from raw material sourcing to final product assembly, meet the required standards. The fact that these audits are conducted by independent bodies adds an extra layer of credibility to the certifications.

Long-Term Business RelationshipsHaving certifications and compliance in place can lead to long-term business relationships. Distributors and retailers are more likely to partner with factories that have these credentials, as they offer a level of assurance that can be passed on to the end consumer.

In conclusion, certifications and compliance are not just about adhering to rules; they are a reflection of a factory’s dedication to excellence, safety, and ethical business practices. They are a crucial factor to consider when choosing an air fryer factory, as they provide a clear indication of the quality and reliability of the products being offered.

Stepping onto the factory floor, you’re greeted by a symphony of activity. The hum of machinery and the clink of tools create a rhythm that speaks volumes about the precision and dedication that goes into each product. Here’s what to look out for as you navigate the heart of production:

The Layout: Observe the flow of the production line. A well-organized layout minimizes waste and ensures a smooth process. It should be easy to follow, with a clear distinction between different stages of production, from raw materials to finished goods.

Cleanliness and Safety: A reliable factory is spotless, with a focus on safety. Check for cleanliness, especially in areas where products are being handled or assembled. Safety equipment like helmets, protective gear, and emergency exits should be readily apparent and in good condition.

The Equipment: The machinery and tools used in the factory can tell you a lot about the quality of the products. Modern, well-maintained equipment is a sign of a factory that values efficiency and quality. Look for advanced technology that may be used for precision cutting, welding, or assembly.

Employee Engagement: The attitude of the workers can be a revealing indicator of the factory’s ethos. Engaged, happy employees are often a sign of a good work environment. Notice how the staff interacts with each other and with the machinery. Are they trained properly? Do they seem confident in their tasks?

Quality Control Measures: Look for signs of rigorous quality control. This could be in the form of inspectors checking products at various stages or automated systems that ensure consistency. A factory that doesn’t skimp on quality control is one you can trust.

Supply Chain Visibility: Being able to see the entire supply chain is crucial. Observe how raw materials are received, stored, and used. Transparency in the supply chain can give you confidence in the factory’s ability to control the quality of its inputs.

Product Development: If possible, speak with the product development team. Understanding their process can provide insights into how the factory stays ahead of trends and adapts to market demands. Innovative thinking and continuous improvement are hallmarks of a reliable manufacturer.

Record Keeping: A reliable factory keeps detailed records. From material certifications to production logs, these documents can provide a comprehensive view of the quality assurance process. Ask to see some of these records and assess their thoroughness.

Customer Interaction: How the factory interacts with its customers can be indicative of its commitment to service. Are there customer service representatives available? Do they seem knowledgeable and responsive? A factory that values customer feedback is likely to prioritize quality.

Certification Displays: Look for certifications that the factory proudly displays. These can range from ISO standards to industry-specific qualifications. These certifications are a testament to the factory’s adherence to international quality benchmarks.

Feedback Loop: Notice if there’s a system in place for collecting and addressing feedback. A factory that actively seeks and responds to customer feedback is committed to improvement and customer satisfaction.

Sustainability Efforts: Modern manufacturers are increasingly focusing on sustainability. Look for any initiatives the factory has implemented, such as recycling programs or energy-efficient practices. This demonstrates a forward-thinking approach and a commitment to the environment.

In the end, visiting the factory is more than just a visual inspection; it’s an opportunity to experience the heartbeat of the manufacturing process. By paying attention to these details, you can gain a deeper understanding of the reliability and quality of the products you’re considering.

Understanding the intricacies of an air fryer factory’s production processes is crucial for ensuring that the products you source are of the highest quality. Here’s a detailed look into what to inspect:

The layout of the factory is a window into its efficiency. As you walk through the aisles, notice the flow of materials and products. A well-organized layout minimizes waste and maximizes productivity.

Inspecting the raw materials is essential. Look for high-quality components and raw materials that meet industry standards. Check for any signs of damage or poor quality, as this can reflect on the final product.

The machinery used in the production line is a testament to the factory’s commitment to quality. Look for modern, well-maintained equipment that can handle the volume of production. Observe how the machines are operated to ensure precision and consistency.

The cleanliness of the factory is a reflection of its hygiene standards. A clean workspace reduces the risk of contamination and ensures that the final product meets safety regulations. Pay attention to the floors, equipment, and storage areas.

Quality control is a non-negotiable aspect of any reputable factory. Watch how products are inspected at various stages of production. Look for automated systems that can detect defects and for skilled workers who manually check the products.

The efficiency of the production line is crucial. Observe how quickly products move through the line without compromising quality. Look for bottlenecks or inefficiencies that could slow down the process or affect product quality.

The use of technology in the production process can greatly impact the final product. Check if the factory employs advanced technology for precision cutting, welding, or assembly. Technology can also help in reducing errors and improving overall product quality.

The packaging area is often overlooked but is equally important. Ensure that the packaging materials are of good quality and that the packaging process is secure and efficient. Observe how the products are handled to prevent damage during transport.

The factory’s ability to handle different orders and customize products is a sign of flexibility. Look for the presence of tools and machinery that can accommodate various sizes and specifications. A factory that can easily adapt to different customer needs is more likely to produce a wide range of high-quality products.

The training of the workforce is a critical factor in maintaining quality. Observe how employees are trained and if there’s a continuous education program in place. Skilled workers are more likely to produce high-quality products and contribute to the factory’s success.

The factory’s waste management practices are also indicative of its environmental responsibility and overall efficiency. Check if there are recycling programs for materials and if the factory adheres to environmental regulations.

The communication between different departments within the factory is essential for smooth operations. Notice how employees interact and if there’s a clear chain of command. Effective communication can prevent misunderstandings and ensure that quality is maintained throughout the production process.

The factory’s record-keeping is a testament to its accountability. Look for detailed records of production runs, quality checks, and any issues that may have arisen. Good record-keeping can help identify patterns and address recurring problems.

Lastly, the overall atmosphere of the factory can give you insights into the company’s culture and values. A factory that takes pride in its work and prioritizes quality will likely produce better products. Observe the attitudes of the employees and the environment they work in to gauge the factory’s commitment to excellence.

Understanding the intricacies of a factory’s supply chain is crucial for ensuring the reliability of the products they produce. Here’s a detailed look into what to evaluate:

The supply chain is like the backbone of a factory, ensuring that raw materials flow smoothly, components are assembled efficiently, and finished goods are delivered on time. Here’s how to evaluate it:

Material Sourcing: Assess the origin of the materials used in the production process. Are they sourced locally or from abroad? Local sourcing can reduce lead times and transportation costs, while also supporting the local economy. It’s also important to consider the sustainability and ethical practices of suppliers.

Supplier Relationships: The quality of the relationship with suppliers is key. A reliable factory maintains strong connections with its suppliers, which can lead to better pricing, faster delivery, and improved communication. Look for suppliers that are committed to quality and have a history of working well with the factory.

Inventory Management: Efficient inventory management is vital for a smooth supply chain. Excessive inventory ties up capital and can lead to waste, while insufficient inventory can cause delays. A factory should have systems in place to balance inventory levels, minimize waste, and ensure that materials are available when needed.

Quality Control: The supply chain is where the rubber meets the road in terms of product quality. Check that the factory has stringent quality control measures in place at every stage of the supply chain. This includes inspecting incoming materials, monitoring the production process, and conducting final inspections before shipping.

Lead Times: The time it takes for materials to be sourced, processed, and delivered can significantly impact the factory’s ability to meet customer demands. Evaluate the lead times for different components and how they affect the overall production timeline.

Flexibility: A robust supply chain should be flexible enough to adapt to changes. This includes the ability to switch suppliers if necessary, handle unexpected delays, and adjust production schedules to meet fluctuating demand.

Logistics and Distribution: The logistics of getting products from the factory to the customer are just as important as the production process itself. Look at the factory’s logistics network, including transportation methods, storage facilities, and distribution partners. A well-established logistics system can ensure that products are delivered promptly and damage-free.

Technology and Data: Modern supply chains rely heavily on technology for tracking and managing inventory, production schedules, and customer orders. Evaluate the factory’s use of technology and data analytics to optimize the supply chain.

Environmental Impact: Consider the environmental impact of the supply chain. A factory that prioritizes sustainability in its supply chain practices may have a more efficient and reliable process overall, as well as a positive brand image.

Cost Management: While cost is always a factor, it’s important to balance cost savings with quality and reliability. A factory that cuts corners on the supply chain may save money in the short term but could end up with higher costs due to increased defects, delays, or customer dissatisfaction.

Customer Feedback: Finally, listen to customer feedback regarding the reliability of the supply chain. If customers are experiencing consistent delivery issues or product defects, it’s a sign that the supply chain may need improvement.

By thoroughly evaluating these aspects of the supply chain, you can gain a clearer picture of how well a factory is positioned to produce and deliver reliable products. It’s an intricate process, but one that is essential for ensuring the longevity and success of any manufacturing operation.

In the world of business, especially when dealing with complex manufacturing processes, clear communication channels are the lifeblood of successful partnerships. They are the bridges that connect suppliers and buyers, ensuring that every detail is understood and every expectation is met. Here’s a closer look at why these channels are so crucial and how they can make or break a business relationship.

Understanding the Language of BusinessCommunication is not just about exchanging information; it’s about understanding the nuances of the language that is unique to the business world. This includes technical jargon, industry-specific terminology, and the ability to convey complex ideas in a concise and precise manner. For instance, when discussing product specifications or delivery timelines, clarity is paramount to avoid misunderstandings that could lead to costly delays.

The Power of Regular UpdatesA reliable communication channel ensures that both parties are kept in the loop at all times. Regular updates can prevent surprises and allow for proactive problem-solving. Imagine a scenario where a supplier is about to run into production issues due to a shortage of raw materials. If the communication channel is effective, the buyer can be informed in advance, and alternative solutions can be explored before it impacts the delivery schedule.

The Importance of DocumentationIn the context of business transactions, documentation is king. Clear communication channels facilitate the creation and sharing of detailed documents, such as contracts, invoices, and technical specifications. These documents serve as a reference point for both parties, ensuring that there is a mutual understanding of the terms and conditions of the agreement.

Building Trust Through TransparencyTransparency is a cornerstone of any strong business relationship. When communication channels are open and honest, it fosters trust between the supplier and the buyer. This trust is vital for long-term partnerships, as it allows for more strategic discussions and the possibility of exploring new opportunities together.

Handling Conflicts and DisputesNo matter how well a business relationship is established, conflicts and disputes can arise. Clear communication channels are essential in resolving these issues promptly and effectively. By having a direct line of communication, parties can address concerns without the need for intermediaries, which can often lead to more efficient and satisfactory resolutions.

Adapting to ChangesThe business environment is dynamic, and changes can happen rapidly. A robust communication system allows for quick adaptation to these changes. Whether it’s a shift in market demand, a change in product specifications, or an emergency situation, the ability to communicate these changes swiftly is crucial for maintaining business continuity.

The Role of TechnologyIn today’s digital age, technology plays a significant role in facilitating clear communication channels. From email and instant messaging to video conferencing and project management tools, there are numerous platforms that can streamline communication. The choice of technology should be based on the specific needs of the business and the preferences of the parties involved.

Cultural SensitivityWhen dealing with international suppliers or buyers, cultural sensitivity becomes an important aspect of communication. Understanding and respecting cultural norms, etiquette, and language barriers can go a long way in ensuring that messages are received and interpreted correctly.

The Value of FeedbackEffective communication channels also include the ability to provide and receive feedback. This two-way street allows for continuous improvement and ensures that both parties are satisfied with the relationship. Regular feedback sessions can help identify areas for growth and address any concerns before they escalate.

In conclusion, clear communication channels are not just about the tools and methods used to convey information; they are about the foundation of trust, understanding, and collaboration that are essential for successful business operations. By investing in these channels, businesses can navigate the complexities of global markets with greater ease and achieve their goals more effectively.

Navigating the complexities of a product’s lifespan often leads consumers to rely on the support and service offered by the manufacturer. Technical support and after-sales service are the pillars that can make or break a company’s reputation in the long run. Let’s delve into what these aspects entail and why they are crucial.

Understanding the Value of Technical Support

When a product is purchased, the buyer expects it to function smoothly. However, technical issues can arise, and when they do, having a reliable technical support system is invaluable. This support can range from basic troubleshooting to in-depth technical assistance.

Troubleshooting Guides and FAQs

A good manufacturer provides comprehensive troubleshooting guides and frequently asked questions (FAQs) on their website. These resources help customers quickly resolve common issues without the need for direct contact. Clear, concise, and easy-to-follow instructions can significantly reduce the frustration of a malfunctioning product.

Live Chat and Call Support

For more complex issues, live chat or call support is essential. Customers should be able to reach out to a representative who can provide immediate assistance. This direct line of communication ensures that problems are addressed promptly and efficiently.

Expertise and Training of Support Staff

The quality of technical support largely depends on the expertise and training of the staff handling customer inquiries. Well-trained support agents can diagnose problems accurately and offer practical solutions, which not only resolves the immediate issue but also builds trust in the brand.

After-Sales Service: Beyond the Warranty

Warranty periods are crucial, but after-sales service should extend beyond this time frame. This includes:

Regular Maintenance Tips

Manufacturers should provide customers with regular maintenance tips to ensure the longevity of their products. These tips can range from cleaning instructions to recommended service intervals.

Replacement Parts Availability

If a part of the product needs to be replaced, the availability of genuine replacement parts is critical. Customers should be able to order these parts easily and at a reasonable cost.

Customer Feedback and Continuous Improvement

After-sales service should include a mechanism for collecting customer feedback. This feedback is vital for identifying recurring issues and making continuous improvements to the product and the service provided.

Training and Education Resources

Some manufacturers offer online training and educational resources to help customers get the most out of their products. These resources can include video tutorials, webinars, and user forums.

Response Time and Efficiency

The speed and efficiency of the response to customer inquiries are indicative of the company’s commitment to excellent after-sales service. A quick response time can make a world of difference in customer satisfaction.

Case Studies and Success Stories

Sharing case studies and success stories can inspire confidence in potential customers. These stories demonstrate how the company has resolved complex issues and satisfied customers in the past.

Transparency in Policies and Procedures

Clear communication about policies and procedures is essential. Customers should know what to expect in terms of service, return policies, and the process for filing complaints.

In conclusion, technical support and after-sales service are not just about fixing problems; they are about building lasting relationships with customers. A company that invests in these areas demonstrates its dedication to quality, reliability, and customer satisfaction.

Finding a reliable air fryer factory can sometimes feel like navigating a maze, but seeking recommendations is like having a map in hand. It’s not just about gathering advice; it’s about tapping into the collective wisdom of those who have gone before you. Here’s how to effectively seek out these valuable recommendations:

Network with Industry ContactsIndustry professionals, such as chefs, kitchen designers, or even competitors, can be a treasure trove of information. Engage in conversations at trade shows, seminars, or local business groups. Often, they’ve dealt with various suppliers and can offer firsthand insights into their experiences.

Online Forums and Social MediaJoin online forums and social media groups dedicated to the kitchen and appliances industry. These platforms are buzzing with discussions about suppliers, factories, and products. Don’t hesitate to ask for recommendations or share your own experiences.

Ask Colleagues and FriendsYour professional network isn’t limited to those in the industry. Friends and family who have recently purchased air fryers or similar kitchen appliances can provide personal recommendations based on their satisfaction with the product and the service they received.

Review Websites and Business DirectoriesWebsites like Yelp, Google Reviews, or industry-specific directories can offer a wealth of information about different factories. Look for patterns in the reviews and take note of the types of feedback that are consistently mentioned.

Attend Trade Shows and ExposThese events are not only a place to see the latest products but also to meet potential suppliers. Attendees often have the opportunity to speak directly with representatives from various factories, which can lead to personalized recommendations.

Local Business AssociationsLocal business associations often have a directory of members, which can include air fryer manufacturers. Contacting these associations can provide you with a list of reputable factories in your area.

Manufacturer Certifications and PartnershipsLook for factories that have certifications or partnerships with well-known brands. This can be a sign that they are trusted and recommended by reputable companies in the industry.

Case Studies and Success StoriesMany factories showcase case studies or success stories on their websites. These stories often come with testimonials from satisfied customers, which can be a strong indicator of their reliability.

Be Mindful of Time and ContextWhen seeking recommendations, consider the context and the time frame. Recommendations from recent projects or purchases are more likely to be relevant and accurate.

Follow Up with QuestionsOnce you have a list of recommended factories, don’t hesitate to follow up with questions. This could include inquiries about their capabilities, quality control processes, and how they handle customer service.

Remember, a recommendation is not just a name but a story—someone’s experience with a particular factory. It’s about understanding the journey they’ve been on and learning from their successes and challenges. By seeking out these stories and experiences, you’re essentially gathering a wealth of information that can guide you toward a reliable air fryer factory.

Navigating the complexities of business relationships, negotiating terms and conditions is an art that can significantly impact the success of your partnership. Whether you’re dealing with a supplier, manufacturer, or service provider, understanding how to effectively negotiate can lead to favorable outcomes. Here’s a detailed look into the intricacies of negotiating terms and conditions:

Understanding the Landscape- Assess the market dynamics and the specific industry you’re operating in. This understanding will help you gauge the typical terms and conditions that are common in your sector.- Recognize the power dynamics at play. Are you the buyer with leverage, or is the supplier in a dominant position? Knowing this can help you tailor your negotiation strategy.

Setting Clear Objectives- Define what you want to achieve with the negotiation. Is it about securing the best price, ensuring quality, or obtaining a longer-term contract?- Be specific about your non-negotiables. What are the absolute must-haves that you won’t compromise on?

Research and Preparation- Conduct thorough research on the supplier or manufacturer. Understand their reputation, track record, and the quality of their products or services.- Prepare a list of comparable offers or alternatives. This can serve as a bargaining chip if the initial terms are not favorable.

Open and Constructive Communication- Enter negotiations with an open mind. Be willing to listen to the other party’s perspective and understand their needs and constraints.- Use a collaborative approach rather than an adversarial one. This can help in building a long-term relationship based on mutual respect.

Flexibility and Compromise- Be prepared to make concessions. No negotiation is one-sided, and finding a middle ground is often the key to success.- However, ensure that any compromise does not undermine your core objectives or the quality of the product or service you expect.

Understanding Legal and Contractual Language- Familiarize yourself with the legal terms and conditions. This includes understanding warranties, delivery schedules, and any penalties for breaches.- If necessary, consult with a legal expert to ensure that the contract is fair and protects your interests.

Addressing Price and Payment Terms- Negotiate the price based on the value you receive. Don’t be afraid to ask for discounts or volume-based pricing.- Discuss payment terms that are favorable to your cash flow, such as extended payment periods or discounts for early payments.

Handling Disputes and Changes- Establish a clear process for handling disputes. This should include how issues will be resolved and the timeline for doing so.- Be prepared to revisit terms and conditions if there are changes in the market or in the relationship between parties.

Long-Term Relationship Building- Remember that negotiations are not just about the immediate deal but also about the future of the relationship.- Focus on creating a win-win scenario that sets the stage for a successful and enduring partnership.

Negotiating intellectual property rights- If the product involves intellectual property, ensure that the terms protect your rights and those of the manufacturer.- Discuss licensing agreements, ownership of improvements, and the rights to use the product in different markets.

Performance Metrics and KPIs- Incorporate performance metrics and key performance indicators (KPIs) into the contract to measure the supplier’s or manufacturer’s performance.- These metrics should align with your business goals and provide a basis for evaluating the success of the partnership.

Exit Strategies- Have a clear exit strategy in place in case the partnership does not work out. This should include how to handle the termination of the contract and any associated costs or penalties.

By approaching negotiations with thorough preparation, clear objectives, and a willingness to communicate and compromise, you can secure terms and conditions that not only meet your immediate needs but also lay the foundation for a strong, long-term business relationship.

Understanding the latest market trends is crucial for any business looking to stay competitive and informed. Here’s how staying updated can make a significant difference:

In a rapidly evolving industry like the air fryer market, being aware of the newest developments can mean the difference between leading the pack or falling behind. From emerging technologies to changing consumer preferences, staying informed about market trends is essential for strategic planning and decision-making.

Social media and online forums are buzzing with discussions about the latest innovations. Keeping an eye on these platforms can provide insights into what customers are talking about, what features they are excited about, and what they are dissatisfied with in current air fryer models. This information can be invaluable when considering new product designs or improvements.

Industry reports and market research studies are another source of information. They often provide detailed analyses of market sizes, growth rates, and consumer behavior. By reviewing these reports, you can gain a comprehensive understanding of the broader market context and identify potential opportunities or threats.

Participating in trade shows and conferences is a direct way to immerse yourself in the latest trends. These events bring together manufacturers, distributors, and consumers, offering a unique opportunity to see the newest products in action and to network with key players in the industry.

The rise of smart appliances has been a significant trend in the kitchen appliances sector. Keeping abreast of advancements in smart technology can help you anticipate the demand for air fryers that integrate with home automation systems or offer remote control features.

Sustainability is another key trend that affects the air fryer market. As consumers become more environmentally conscious, they are looking for appliances that are energy-efficient and made from sustainable materials. Being aware of these preferences can help you align your product offerings with consumer values.

The health and wellness trend continues to influence the appliance industry, with an increasing focus on healthy cooking methods. Air fryers that tout their ability to cook with less oil or offer healthier cooking options may find a receptive market.

Globalization plays a role too, with the air fryer market expanding into new regions and demographics. Understanding these new markets and adapting marketing strategies accordingly can open up new avenues for growth.

Seasonal trends can also impact the air fryer market. For instance, certain models may see increased demand during specific seasons, like the holiday season or summer when outdoor grilling is popular. Being attuned to these seasonal fluctuations can help you manage inventory and production schedules more effectively.

Lastly, staying informed about regulatory changes is crucial, as new standards and certifications can affect product compliance and marketability. Keeping up with these changes ensures that your products remain competitive and compliant with all relevant regulations.

In summary, staying informed about market trends is a multifaceted endeavor that requires a combination of active monitoring, strategic analysis, and participation in industry events. By doing so, businesses can make informed decisions, anticipate market shifts, and ultimately stay ahead in a dynamic and competitive landscape.