Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the heart of the bustling kitchen appliances industry, there lies a factory that has not only mastered the art of sandwich pressing but has also become a beacon of innovation and quality. This factory, known for its heavy-duty sandwich presses, stands as a testament to the evolving culinary landscape and the ever-growing demand for convenience and excellence in the food preparation process. Join us as we delve into the intricate details of this factory’s commitment to crafting not just sandwiches, but experiences.

The Powerhouse of Sandwich Press Manufacturing

Beneath the towering steel structures and the hum of efficient machinery, lies the beating heart of the sandwich press manufacturing industry. This factory, a veritable powerhouse, stands as a testament to the meticulous craftsmanship and innovative engineering that goes into creating the perfect sandwich press. With a sprawling facility that stretches across acres, the factory is a sight to behold, a testament to the scale and precision required to produce these kitchen essentials.

From the moment raw materials arrive at the factory’s gates, they embark on a journey of transformation. The factory’s logistics are a well-oiled machine, ensuring that every component finds its place without a hitch. The factory floor is a symphony of activity, with workers in a dance of precision, each step and motion contributing to the final product.

The manufacturing process is a marvel of modern engineering. Advanced machinery, some of which is proprietary to the factory, shapes and forms the metal into the foundational components of the sandwich press. These components are then meticulously welded together, with robotic arms ensuring seamless joins that would be impossible by human hands alone.

The factory prides itself on the quality of its materials. High-grade stainless steel is used for the pressing surfaces, ensuring durability and longevity. The heat-resistant handles and the non-stick coatings are all designed to provide the user with a seamless and enjoyable sandwich-making experience.

As the frames take shape, they are sent to the finishing department, where skilled artisans give them a polished finish. The attention to detail is unparalleled, with every corner and edge inspected for perfection. This is not just a factory; it’s a workshop of fine craftsmanship, where the art of sandwich pressing is elevated to an industrial level.

The heart of the factory is its assembly line, where the magic happens. Here, the individual components come together to form a cohesive unit. Workers, trained to the highest standards, ensure that each sandwich press is not just a product but a work of art. They test the pressure mechanisms, check the alignment of the plates, and verify the functionality of the heat controls.

The factory’s commitment to innovation is evident in its R&D department, a hub of creativity and problem-solving. Engineers and designers work tirelessly to push the boundaries of what a sandwich press can be. They experiment with new materials, explore different designs, and constantly seek ways to improve the user experience.

Quality control is a cornerstone of the factory’s operations. At every stage of production, products are rigorously tested to meet the highest standards. From the initial metalwork to the final packaging, every sandwich press is inspected for defects, ensuring that only the best leave the factory.

The factory’s attention to sustainability is also commendable. It has invested in energy-efficient equipment and recycling programs to minimize its environmental impact. The factory is not just a producer of sandwich presses; it is a responsible member of the global community.

As the day winds down, the factory comes alive with a sense of pride. The rows of completed sandwich presses, gleaming under the lights, are a visual representation of the factory’s dedication to excellence. It’s not just about making sandwiches; it’s about creating a tool that can bring joy and convenience to homes and kitchens around the world.

In the heart of this powerhouse, where precision meets passion, the future of sandwich pressing is being shaped. The factory is not just a place of work; it’s a beacon of innovation, a testament to the relentless pursuit of perfection in every aspect of its craft.

In the heart of the sandwich press manufacturing sector, there lies an art form that’s as intricate as it is deceptively simple. The engineering behind crafting these culinary companions is a blend of precision, innovation, and a deep understanding of the needs of both professional chefs and home cooks.

The sandwich press is more than just a device that squishes bread; it’s a tool that shapes the very essence of a meal. From the moment raw ingredients are assembled, the sandwich press begins to work its magic, transforming a humble stack of bread, cheese, and fillings into a masterpiece that delights the senses.

The design of a sandwich press is a delicate balance of form and function. The materials used are often a mix of high-quality stainless steel and heat-resistant plastics, ensuring durability and longevity. The heating elements are meticulously placed to distribute heat evenly across the surface, so that every bite is uniformly toasted and warm.

In the engineering process, the focus is not just on the heat but also on the pressure. The pressure mechanism is a critical component, as it compresses the sandwich, locking in flavors and ensuring that the fillings are uniformly distributed. The engineering team meticulously tests and adjusts the pressure to ensure that each press yields the perfect sandwich, every time.

The handle and grip design are often overlooked but are crucial for user comfort and safety. Ergonomic handles are crafted to fit the hand comfortably, reducing strain and fatigue during prolonged use. Safety features, such as heat-resistant coatings and locking mechanisms, are integrated to prevent accidents and to ensure that the sandwich press is a tool that can be used with confidence.

One of the standout features of modern sandwich presses is the inclusion of non-stick surfaces. These surfaces are not only easy to clean but also prevent the bread from sticking, ensuring that the sandwich can be released with ease. The engineering behind these coatings is a testament to the factory’s commitment to quality and customer satisfaction.

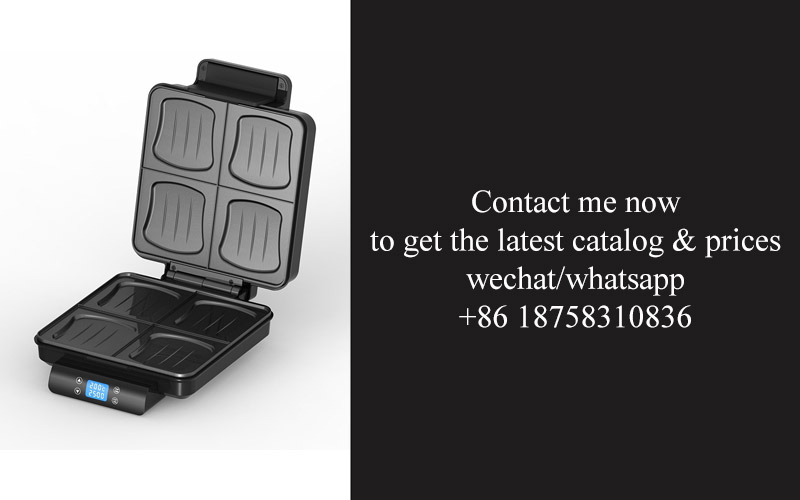

Innovation doesn’t stop at the design of the sandwich press itself. The factory has also introduced smart features that allow users to program their desired cooking time and temperature. This level of customization ensures that whether you’re making a classic ham and cheese or a gourmet avocado toast, the sandwich press can be tailored to your specific taste preferences.

The engineering team also pays close attention to the aesthetics of the sandwich press. Aesthetics might not seem like a critical factor, but a sandwich press that looks as good as it performs can be a centerpiece in any kitchen. The sleek lines, modern finishes, and sometimes even the incorporation of unique materials like copper or brushed steel, make these appliances not just functional but also a statement piece.

Moreover, the sandwich press is engineered to be versatile. Some models are designed to cook a variety of foods, from paninis to grilled cheese, to even sandwiches with fillings like vegetables or meats that require a bit more heat to cook through. This versatility is achieved through the design of the heating elements and the adjustable pressure plates.

In the world of sandwich engineering, the factory has also embraced sustainability. By using energy-efficient heating elements and materials that are easy to recycle, the sandwich press is not just a kitchen gadget but also a responsible choice for the environment.

The art of sandwich engineering is a blend of traditional craftsmanship and cutting-edge technology. It’s a testament to the factory’s dedication to creating a product that not only satisfies the taste buds but also stands the test of time. Through each carefully designed component and thoughtful feature, the sandwich press becomes more than just a tool—it becomes an extension of the culinary experience.

In the heart of the factory, where precision meets passion, innovations on the production line are a testament to the art of sandwich engineering. The machinery hums with the rhythm of innovation, each piece meticulously crafted to transform simple ingredients into culinary masterpieces.

The factory boasts state-of-the-art robotic arms that deftly place sandwiches into the heavy-duty sandwich presses. These arms are programmed with an intricate dance of movements, ensuring that every sandwich is pressed with the perfect amount of pressure. The result? A golden brown crust that locks in the flavors and moisture, making each bite a delightful experience.

At the core of these innovations is the thermal management system. The presses are equipped with advanced temperature sensors that monitor the heat distribution throughout the cooking process. This ensures that every sandwich is cooked to a consistent perfection, no matter the size or thickness of the bread. The technology is so precise that it can even accommodate artisanal breads with unique textures and crusts.

The sandwich presses themselves are a marvel of engineering. They are built with a sturdy, heat-resistant material that can withstand the intense pressure required to create a perfect sandwich. The design is not just about durability; it’s also about ease of use. The sleek, modern look of the presses complements any kitchen environment, from the bustling streets of a busy city to the cozy confines of a home kitchen.

One of the most significant innovations is the variable pressure feature. Users can adjust the pressure level according to their preference, whether they prefer a soft, chewy texture or a crisp, crunchy crust. This flexibility is a game-changer in the world of sandwich making, allowing for a personalized touch in every bite.

The factory’s commitment to sustainability is evident in the energy-efficient designs of the sandwich presses. The presses are equipped with eco-friendly insulation that reduces heat loss and energy consumption. This not only saves on costs for the end-user but also minimizes the environmental impact of the production process.

In the realm of health and safety, the factory has introduced anti-slip mats and safety guards on the presses. These features protect the operators from accidents while ensuring that the sandwiches are cooked safely. The mats also prevent any unwanted movement of the sandwich during the pressing process, guaranteeing that each one comes out just right.

The production line is not just about the presses; it’s also about the accessories. The factory offers a range of high-quality accessories that complement the sandwich presses, including non-stick surfaces, drip trays, and easy-to-clean components. These additions make the sandwich-making experience more enjoyable and hassle-free.

Innovation is not limited to the production of the sandwich presses; it extends to the factory’s approach to quality control. Advanced sensors and cameras monitor the entire production process, from the unloading of raw materials to the final packaging. This ensures that every sandwich press that leaves the factory meets the highest standards of quality and safety.

The factory’s engineers are constantly at work, experimenting with new materials and technologies. They are exploring the use of smart sensors that can provide real-time feedback on the cooking process, allowing users to adjust their sandwich presses remotely. This kind of technology could revolutionize the way people cook at home, making it as easy as a few taps on a smartphone.

In the world of sandwich engineering, the factory’s production line is a beacon of innovation. It’s a place where every detail is scrutinized, every improvement celebrated, and where the art of creating the perfect sandwich is taken to new heights. From the design of the presses to the accessories that accompany them, the factory’s dedication to excellence is clear, and it’s reflected in the quality of the product that ends up in the hands of consumers.

The sandwich press industry is a dynamic landscape, and staying ahead in this competitive market requires a keen sense of the pulse of the industry. Here’s a glimpse into how manufacturers navigate this terrain with precision and foresight.

In an era where technology meets culinary creativity, the landscape of sandwich press manufacturing has evolved beyond mere toasting capabilities. Innovations in materials, design, and functionality have redefined the art of crafting the perfect sandwich. Let’s delve into some of the latest developments that are reshaping the industry.

One significant trend is the integration of smart technology into sandwich presses. These modern gadgets don’t just toast; they monitor and adjust heat levels, timing, and pressure to ensure consistent and even cooking every time. The inclusion of digital displays and customizable settings has become a standard, allowing users to achieve the desired sandwich texture and color.

Another innovation is the shift towards eco-friendly materials. Sandwich presses are now being manufactured using sustainable resources and recyclable components. This not only appeals to environmentally conscious consumers but also reduces the carbon footprint of the manufacturing process. The industry’s commitment to green initiatives is evident in the use of non-toxic coatings and energy-efficient heating elements.

In the realm of design, manufacturers are focusing on ergonomics and user convenience. Compact and sleek models have replaced the bulky and cumbersome predecessors, making space-saving a key selling point. Additionally, the inclusion of safety features such as automatic shut-off timers and cool-touch surfaces has made sandwich presses not just a kitchen tool but a safe one as well.

The market is also witnessing a surge in customization options. From adjustable press plates that cater to different sandwich sizes to interchangeable cooking grids that allow for grilling, frying, or toasting, the industry is responding to the consumer’s desire for personalization. These features make sandwich presses versatile enough to tackle a variety of culinary tasks beyond the classic bread-and-protein sandwich.

On the technological front, the advent of Bluetooth connectivity and mobile app integration has brought a new level of interaction between the user and their sandwich press. These apps offer a plethora of recipes, cooking tips, and even community sharing, turning the sandwich press into a part of a connected kitchen ecosystem.

Moreover, the industry is not immune to the impact of global trends. For instance, the popularity of vegan and gluten-free diets has led to the development of sandwich presses that can handle delicate ingredients without damaging them. The rise of the health-conscious consumer has spurred the creation of models that can toast whole grain breads without scorching them or charbroil vegetables to perfection.

As for market navigation, sandwich press manufacturers are constantly analyzing consumer behavior through market research and trend analysis. Understanding which features are most valued by different consumer segments helps them tailor their products to meet specific needs. For example, young professionals might prioritize ease of use and portability, while home bakers might seek premium materials and superior performance.

Social media and influencer partnerships have become another critical tool for navigating the market. Collaborating with food bloggers and chefs not only increases brand visibility but also provides valuable feedback on new product releases. These influencers serve as conduits, helping manufacturers gauge public reception and adjust their strategies accordingly.

Lastly, the global reach of the sandwich press market is expanding, with emerging markets presenting new opportunities. Manufacturers are diversifying their product lines to cater to different cultural preferences and dietary norms. This expansion into international markets has become a strategic move for long-term growth and profitability.

In summary, navigating the market with a keen eye involves a multi-faceted approach: embracing technology, focusing on sustainability, prioritizing user convenience, offering customization, staying attuned to global trends, engaging with consumers through digital platforms, and expanding into new markets. These strategies collectively ensure that sandwich press manufacturers continue to meet the evolving demands of their customers in an ever-changing culinary landscape.

In the heart of sandwich engineering, precision is the cornerstone of crafting quality sandwiches. It’s a meticulous dance between science and culinary art, where each ingredient and step is carefully orchestrated to ensure perfection. Here’s how it all comes together:

The careful selection of ingredients is paramount. Each grain of bread, slice of cheese, and dollop of condiment must be chosen for its quality and flavor profile. The factory’s team of sandwich artisans inspects every item, ensuring that only the freshest and highest-grade ingredients make their way onto the production line.

The bread is a canvas, and the way it’s handled can make or break a sandwich. The factory employs skilled bakers who understand the texture and structure of bread. They craft each loaf to ensure it’s fluffy, yet firm enough to hold the sandwich’s fillings without squishing.

The slicing of vegetables, meats, and cheese is an art form in itself. Precision slicers are used to create uniform cuts, ensuring that every piece is the perfect size and thickness. This consistency is key to maintaining the sandwich’s integrity during the cooking process.

The assembly line is a marvel of efficiency and cleanliness. Workers don gloves and caps, maintaining a sterile environment to prevent contamination. As they stack each layer, they’re mindful of the balance and distribution of flavors, ensuring that no single ingredient overpowers the others.

Once assembled, the sandwiches are placed into the heavy-duty sandwich presses. These presses apply even pressure, cooking the sandwich to a golden-brown perfection. The heat is carefully controlled to ensure that the bread is toasted just right, without becoming too crisp or burning.

Quality control is rigorous. Sensors and cameras monitor the cooking process, checking for consistent results. If a sandwich doesn’t meet the stringent quality standards, it’s immediately flagged and removed from the line. This ensures that every sandwich leaving the factory is of the highest quality.

The cooling process is equally important. Sandwiches are cooled to room temperature before they’re packaged, which helps maintain their freshness and texture. This also allows the flavors to meld together, creating a more complex taste experience.

Packaging is designed to keep the sandwiches fresh for as long as possible. The factory uses airtight containers that protect against moisture and oxygen, extending the shelf life and ensuring that the sandwiches arrive at their destination in optimal condition.

In the realm of sandwich crafting, attention to detail is everything. The factory’s commitment to quality is evident in every aspect of the process, from ingredient selection to packaging. It’s this unwavering dedication to excellence that sets their sandwiches apart, making them a favorite among sandwich enthusiasts and foodservice providers alike.

The precision with which the factory handles each stage of sandwich production reflects a deep understanding of the craft. It’s not just about making sandwiches; it’s about creating an experience, where every bite is a testament to the artistry and care that goes into crafting quality sandwiches.

In the ever-evolving landscape of the sandwich press industry, the factory has long been a beacon of innovation and excellence. Its vision for the future is a testament to its commitment to staying ahead in a rapidly changing market. Here’s a glimpse into the factory’s ambitious plans:

The factory’s vision for the future encompasses a seamless fusion of technology and culinary art. It aims to push the boundaries of what is possible in sandwich preparation, ensuring that each product not only meets but exceeds the highest standards of quality.

One cornerstone of this vision is the integration of AI into the production line. By deploying advanced algorithms, the factory envisions a future where sandwich presses are not just tools but intelligent companions. These AI-driven machines could learn from each user, adapting their pressure, timing, and heating elements to deliver the perfect sandwich every time.

Sustainability is another pillar of the factory’s future vision. With environmental concerns at the forefront of global consciousness, the factory is dedicated to reducing its ecological footprint. This includes the development of eco-friendly materials for sandwich press construction and exploring renewable energy sources to power its manufacturing process.

The factory is also eyeing global expansion as a key component of its future strategy. With the intention to cater to a diverse range of palates, the factory plans to introduce sandwich presses that cater to different cultural preferences and dietary needs, from vegan options to those tailored for health-conscious consumers.

Within the factory itself, a significant shift towards employee empowerment is underway. The vision is to create a workspace where innovation is encouraged and where every worker has a voice in shaping the products of tomorrow. This collaborative approach is expected to lead to a more dynamic and creative environment.

Innovation isn’t limited to the factory floor; it’s also about reimagining the customer experience. The factory aims to develop an interactive platform where users can not only purchase their sandwich presses but also access recipes, cooking tips, and community forums. This would create a community of sandwich enthusiasts, fostering loyalty and feedback that can drive further product development.

The factory’s future also involves a strong focus on research and development. By investing in new materials, heating technologies, and ergonomic designs, the factory intends to maintain its position as a leader in the sandwich press industry. This includes exploring how to incorporate health benefits into sandwich presses, such as adjustable heat settings for various types of bread or fillings.

The vision also extends to social responsibility. The factory is looking into partnerships with local and global communities to support initiatives that promote healthy eating and cooking. By engaging in educational programs and sharing its knowledge, the factory aspires to contribute to a healthier society.

In the realm of marketing, the factory is poised to embrace a more personalized approach. Through data analytics, the factory plans to tailor its marketing strategies to individual customer preferences, offering bespoke solutions that resonate with their needs and aspirations.

Finally, the factory’s vision for the future is about staying adaptable. In an industry that can be influenced by shifting consumer trends, economic changes, and technological advancements, the factory is committed to being flexible and responsive to these changes, ensuring its longevity and relevance.

This future vision is not just about producing the latest in sandwich presses; it’s about creating a legacy that values quality, innovation, and the well-being of people and the planet. The factory’s journey towards this future is a testament to its determination to remain at the forefront of a sandwich revolution.

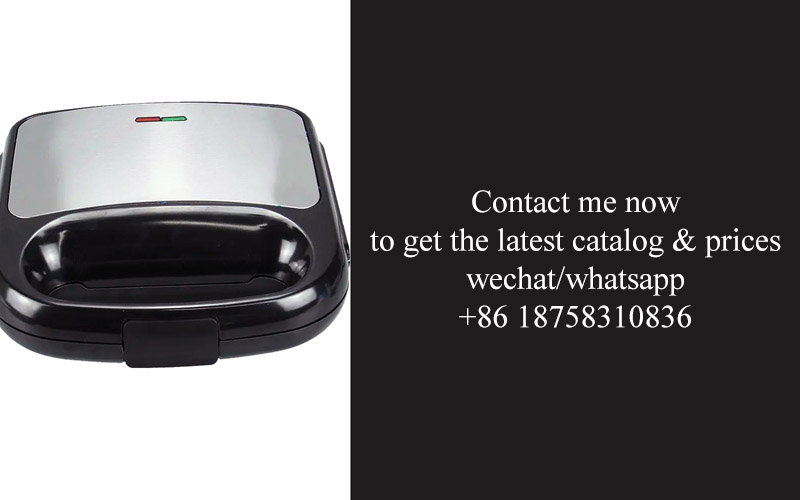

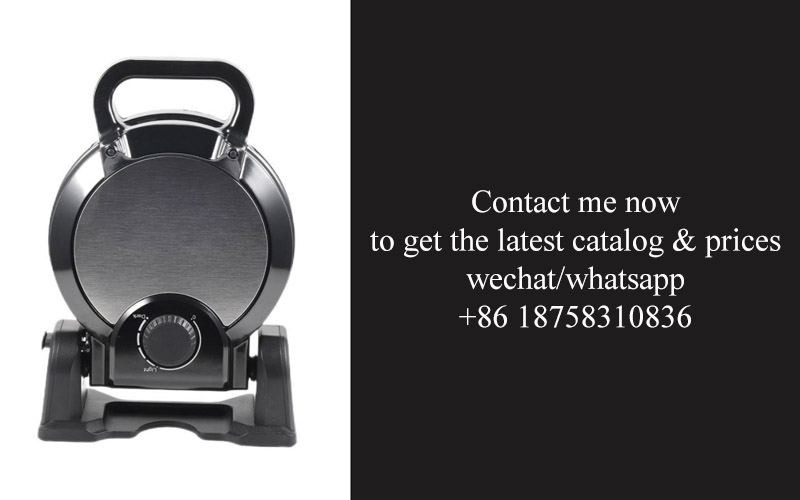

In the heart of the bustling sandwich press manufacturing facility, a diverse array of products awaits inspection. Each piece is a testament to the factory’s commitment to quality and innovation. From compact models perfect for home use to robust units designed for commercial kitchens, the factory’s offerings cater to a wide range of customers.

The factory’s sandwich presses are not just appliances; they are precision-engineered tools that ensure every sandwich is crafted to perfection. The sleek designs are not just visually appealing but also functional, with features that make the process of pressing a joy rather than a chore.

One of the standout products is the “ProBake” series, known for its heavy-duty construction and precise heat control. These presses are a favorite among professional chefs and home enthusiasts alike. The non-stick surfaces ensure that sandwiches release effortlessly, while the even heat distribution guarantees that every layer is cooked to the perfect shade of golden brown.

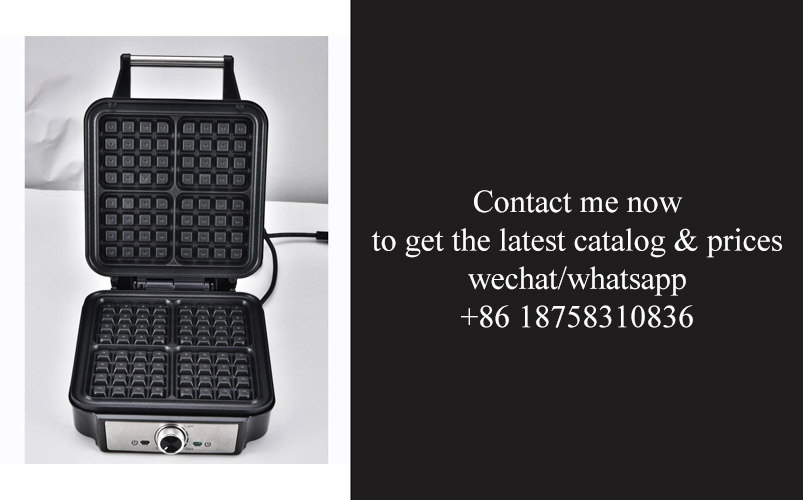

For those who prefer a more rustic approach, the “GrillMaster” line offers a grilling option that infuses a smoky flavor into the sandwich. The unique design allows for a double-sided cooking process, sealing in the flavors and textures that make grilled sandwiches so delightful.

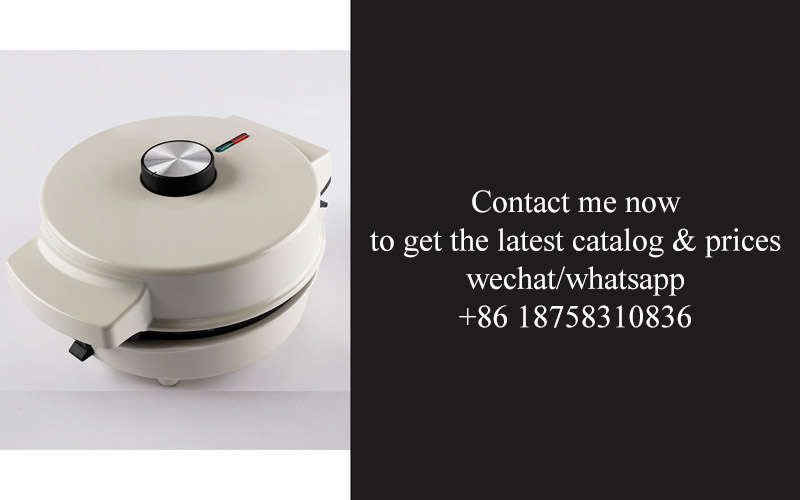

The “SpeedChef” series is a game-changer for busy individuals and fast-food establishments. These compact presses can churn out sandwiches in record time, without compromising on quality. The quick-cook feature is a hit among customers who value efficiency without sacrificing taste.

The “ArtisanTouch” collection is aimed at those who appreciate the finer details of sandwich making. These presses come with interchangeable plates, allowing for a variety of cooking styles, from crispy to soft. The attention to detail is evident in the elegant handle design and the sturdy build that promises longevity.

In addition to sandwich presses, the factory offers a range of accessories to enhance the sandwich-making experience. From high-quality bread warmers to precision measuring tools, these additions are crafted with the same level of care as the presses themselves.

The “SignatureSeries” is where the factory showcases its most luxurious and customized products. These units are often tailored to the specific needs of gourmet restaurants and high-end food service providers. The craftsmanship is unparalleled, with features like adjustable heat settings and custom branding options.

The factory also prides itself on its eco-friendly line, the “GreenChef” collection. These presses are designed with sustainability in mind, using materials that are recyclable and energy-efficient. The eco-conscious approach is a testament to the factory’s commitment to the environment and its customers’ health.

Each product undergoes rigorous testing to ensure it meets the factory’s stringent quality standards. The team of skilled technicians meticulously examines the construction, functionality, and safety of every sandwich press before it leaves the factory floor.

The factory’s dedication to excellence is also reflected in its customer service. From the moment a customer places an order, they are guided through the process by knowledgeable staff who are eager to provide solutions to any challenges they may face.

The product range at the factory is a blend of tradition and innovation, offering something for everyone from the casual home cook to the seasoned professional. With each press, the factory is not just crafting a sandwich maker; it’s creating an experience that brings joy and satisfaction to every bite.

The factory’s commitment to sustainability is not just a buzzword; it’s woven into the very fabric of its operations. From the moment materials are sourced to the final product assembly, every step is meticulously planned to minimize environmental impact.

From raw materials sourcing to the end of life cycle, the factory implements a rigorous selection process for sustainable resources. They prioritize locally sourced materials to reduce transportation emissions and choose suppliers who adhere to eco-friendly practices. This commitment to sourcing ensures that the sandwich presses are not only high-quality but also environmentally responsible.

Energy efficiency is at the heart of the factory’s operations. Advanced manufacturing equipment is used to reduce energy consumption during production. Solar panels and energy-efficient lighting are installed throughout the facility, and regular maintenance ensures that these systems operate at peak performance. The factory’s energy-saving initiatives have led to a significant decrease in its carbon footprint.

Waste reduction is another cornerstone of the factory’s sustainability strategy. They have implemented a comprehensive recycling program that covers everything from paper and cardboard to plastic and metal. Additionally, any leftover materials from production are repurposed or recycled, minimizing waste sent to landfills. The factory even encourages employees to bring their own reusable water bottles and mugs, fostering a culture of sustainability within the workplace.

Innovation in product design is a key factor in the factory’s commitment to sustainability. The sandwich presses are engineered with components that can be easily replaced or recycled, reducing the need for disposal. The materials used are durable, which means the presses have a longer lifespan and less frequent replacements. This not only benefits the environment but also ensures that customers get the most value out of their purchase.

The factory also educates its workforce on the importance of sustainability. Regular training sessions are held to inform employees about the company’s environmental initiatives and how they can contribute to these efforts. By involving employees in the sustainability journey, the factory creates a community that is passionate about making a positive impact.

Community outreach is a vital part of the factory’s sustainability mission. They actively participate in local environmental programs and initiatives, supporting clean-up projects, tree planting, and conservation efforts. By engaging with the community, the factory demonstrates its dedication to a greener future for all.

The factory’s supply chain is carefully managed to ensure that sustainable practices are followed at every stage. They work closely with partners who share the same values and hold them accountable for their environmental impact. This collaboration ensures that the entire supply chain is aligned with the factory’s sustainability goals.

The factory’s commitment to sustainability is also reflected in its approach to customer service. They provide detailed information about the environmental benefits of their products and offer advice on proper disposal or recycling at the end of the product’s life. This transparency helps customers make informed choices that align with their own sustainability values.

As the factory continues to evolve, they are investing in research and development to explore new, sustainable materials and technologies. The goal is to lead the industry in sustainable manufacturing practices, not just follow them. This forward-thinking approach ensures that the factory remains at the forefront of environmental stewardship.

In summary, the factory’s commitment to sustainability is a multi-faceted endeavor that touches every aspect of its operations. By focusing on sustainable sourcing, energy efficiency, waste reduction, and community involvement, the factory is not just crafting quality sandwich presses; it’s building a more sustainable future for everyone.

In the ever-evolving landscape of the sandwich press industry, partnerships and collaborations play a pivotal role in driving innovation and growth. Here’s a glimpse into how the factory forges these vital connections:

The factory understands that success in the sandwich press market isn’t just about manufacturing; it’s about creating a network of like-minded professionals. They’ve established strategic alliances with key suppliers who provide high-quality materials, ensuring that every sandwich press that rolls off the line is a testament to precision and durability.

Collaborations with design firms have led to the development of sandwich presses that are not only functional but also aesthetically pleasing. The factory has embraced the concept of ‘form follows function,’ blending modern design elements with the practical needs of the consumer.

Innovation is at the heart of the factory’s ethos, and they’ve nurtured partnerships with cutting-edge research institutions to explore new technologies and materials. This has allowed them to introduce features like programmable settings and energy-efficient heating elements that have become industry standards.

The factory has also formed alliances with culinary schools and chefs, seeking their expertise to refine the cooking performance of their sandwich presses. These partnerships have resulted in appliances that cater to both the home chef and the professional kitchen, ensuring consistent and delicious results every time.

They’ve invested in collaborative marketing campaigns with renowned food bloggers and influencers, who showcase the versatility of their sandwich presses in creating everything from classic melts to gourmet sliders. This has helped to expand their reach and build a loyal customer base.

The factory has taken a proactive approach to sustainability by partnering with environmental organizations. They’ve implemented recycling programs and are committed to sourcing materials that are both sustainable and responsibly harvested.

In the realm of international trade, the factory has forged partnerships with distributors across the globe, ensuring that their products are available in diverse markets. These relationships are built on mutual respect and a shared vision for the future of the sandwich press industry.

The factory has also engaged in cross-industry collaborations, such as teaming up with kitchen appliance repair services to offer extended warranties and customer support. This comprehensive approach to customer service has set them apart from competitors.

Collaborations with tech companies have allowed the factory to integrate smart features into their sandwich presses, catering to the growing demand for connected kitchen appliances. This integration has opened up new avenues for innovation and has positioned the factory as a leader in the smart kitchen revolution.

The factory’s commitment to partnerships and collaborations is evident in their continuous pursuit of excellence. By working with a diverse range of stakeholders, they’re able to stay ahead of market trends and deliver products that meet the evolving needs of consumers worldwide.

Navigating the intricate landscape of the sandwich press market, the factory has established a reputation for its keen insights and strategic partnerships. From local artisans to global giants, these collaborations have not only fueled innovation but also expanded the factory’s reach and influence.

Our factory’s commitment to quality is unwavering, and this extends to the materials we source and the processes we employ. By working closely with suppliers who share our values, we ensure that every component meets the highest standards of excellence. This collaborative approach has allowed us to develop a network of trusted partners who are as dedicated to sustainability and innovation as we are.

In the realm of design, our factory has forged partnerships with leading industrial designers to push the boundaries of what a sandwich press can be. These collaborations have resulted in a range of products that not only excel in functionality but also in aesthetic appeal. The fusion of creative minds has birthed some truly unique and eye-catching designs that resonate with consumers looking for something beyond the ordinary.

The factory’s partnerships also extend to research institutions and universities. By collaborating with these academic powerhouses, we gain access to cutting-edge research and development, ensuring that our products are at the forefront of technological advancements. This exchange of knowledge has been pivotal in our ability to anticipate market trends and develop solutions that cater to evolving consumer needs.

In the world of marketing, the factory has formed strategic alliances with influential figures and brands. These partnerships have helped us tap into new markets and reach a broader audience. By associating our brand with well-known entities, we enhance our credibility and position ourselves as a leader in the sandwich press industry.

Our commitment to sustainability is not just a buzzword; it’s a core value that drives our collaborations. We have joined forces with environmental organizations and NGOs to develop eco-friendly manufacturing practices and to ensure that our products are produced with minimal impact on the environment. This has not only won us the respect of consumers who prioritize sustainability but has also opened doors to new markets where green initiatives are a priority.

In the realm of distribution, the factory has forged strong relationships with logistics companies and retailers. These partnerships are crucial for ensuring that our products reach customers efficiently and in perfect condition. By working with reliable logistics providers, we can offer timely delivery and exceptional customer service, which are essential for building long-term relationships with our clients.

Our collaborations also involve continuous education and training programs. We believe that the knowledge and skills of our employees are the backbone of our success. By partnering with training institutions, we provide our team with the opportunity to learn and grow, which in turn enhances the quality of our products and services.

In the digital age, the factory has embraced e-commerce and online marketing partnerships. By aligning with digital marketing experts and e-commerce platforms, we have expanded our online presence and made our products more accessible to a global audience. These partnerships have been instrumental in driving online sales and establishing our brand as a leader in the digital marketplace.

The factory’s commitment to partnerships and collaborations is a testament to our dedication to excellence. By continually seeking out and nurturing these relationships, we are able to innovate, grow, and adapt to the changing demands of the market. Whether it’s through design, sustainability, distribution, or digital marketing, these partnerships are the threads that weave together the tapestry of our success.