Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As we delve into the modern era of kitchen appliances, it’s fascinating to observe how technology continues to reshape the way we prepare our meals. One such innovation that has captured the culinary world’s attention is the rise of the automated air fryer assembly line. This game-changing approach not only enhances efficiency and quality but also paves the way for a new wave of innovative kitchen gadgets. Let’s explore the evolution of cooking technology, the impact of automated assembly lines, and the exciting developments that are shaping the future of automated cooking appliances.

The journey of cooking technology is a fascinating tale of human ingenuity and innovation, reflecting the evolution of our relationship with food and the way we prepare it. From the ancient hearths where our ancestors roasted meats to the sleek, modern kitchens of today, the evolution of cooking technology has been marked by leaps and bounds in efficiency, convenience, and culinary possibilities.

In the earliest days, cooking was a rudimentary process, largely reliant on the natural elements of fire and heat. People used open fires to cook their food, often on simple stones or primitive pots. These pots were made from materials like clay, and their shapes and sizes varied depending on the culture and the resources available.

As societies progressed, so did their methods of cooking. The invention of the bellows around 5000 BCE allowed for the creation of the first metalworking techniques, which in turn led to the development of more sophisticated cookware.,,。

The rise of civilization also saw the birth of specialized cooking technologies. The use of the hearth, which was enclosed to control the flame, allowed for more consistent cooking temperatures. In ancient Greece and Rome, brick ovens were constructed, which were a precursor to the modern day oven.

Throughout history, cooking methods have been influenced by cultural exchanges and advancements in technology. For instance, the Arab world introduced the use of sugar, spices, and the double boiler, which greatly influenced European cuisine. The discovery of new lands brought new ingredients, such as tomatoes, potatoes, and chocolate, which expanded the palette of possible dishes.

The industrial revolution in the 18th and 19th centuries was a turning point for cooking technology. The development of the steam engine powered mechanical stoves and later on, electric cookers. These innovations allowed for more precise control over heat and reduced the need for constant supervision, leading to more efficient and safer cooking practices.

The 20th century saw the advent of mass-produced kitchen appliances, such as the electric refrigerator, the blender, and the food processor. These devices not only made cooking faster but also opened up a world of new culinary possibilities, enabling home cooks to experiment with recipes and ingredients that were previously difficult to work with.

In recent decades, technology has continued to advance at a rapid pace. Advances in materials science have led to the creation of non-stick cookware, which requires less oil and is easier to clean. Induction cooktops have replaced traditional electric and gas burners, offering faster and more energy-efficient cooking.

Furthermore, the integration of smart technology into kitchen appliances has brought about a new era of connectivity and convenience. Smart ovens, smart refrigerators, and even smart coffee makers can be controlled remotely through smartphones, allowing for greater personalization and efficiency.

The evolution of cooking technology has also had a significant impact on food preservation. Refrigeration, freezing, and canning have revolutionized the way we store and consume food, reducing waste and extending the shelf life of produce and meats.

Today, we find ourselves at the cusp of yet another technological revolution. The rise of artificial intelligence and machine learning is poised to transform cooking even further. From automated cooking robots to 3D food printers, the future of cooking promises to be a blend of precision, innovation, and creativity.

In conclusion, the evolution of cooking technology is a testament to human creativity and the ever-growing quest for convenience, efficiency, and culinary excellence. As we continue to innovate and push the boundaries of what’s possible in the kitchen, the future looks bright, with boundless possibilities for the way we cook and eat.

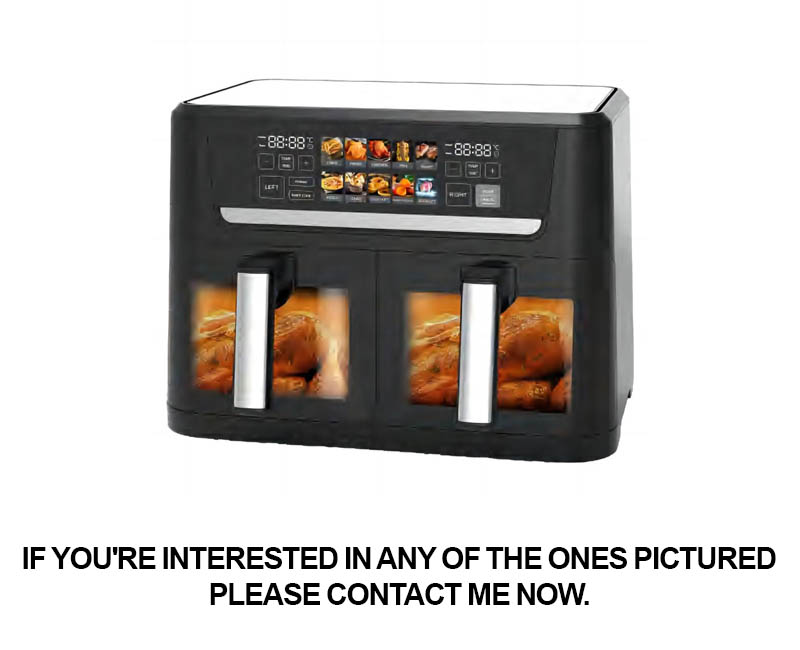

The air fryer has emerged as a true game-changer in the kitchen appliance landscape, transforming the way we approach cooking and health. Once a niche product, it has now become a staple in many households, offering a blend of convenience, health benefits, and culinary versatility.

Once confined to deep-frying, the concept of frying has been revolutionized by the air fryer. This innovative appliance uses a circulating fan and hot air to cook food, significantly reducing the amount of oil needed. The result is a crispy exterior with a tender interior, a hallmark of traditional fried foods, but with a fraction of the fat content.

The health-conscious consumer has been particularly drawn to the air fryer. With the growing awareness of heart disease and obesity, the air fryer’s ability to offer fried food without the guilt has made it a hit. It’s a win-win for those looking to maintain a balanced diet while still indulging in their favorite fried treats.

Not only is the air fryer a health-forward choice, but it’s also a time-saver. The cooking process is quicker than conventional frying, and the appliance often comes with features like adjustable temperature settings and automatic shut-off, allowing for hands-off cooking. This has made it a favorite among busy professionals and families alike.

One of the most appealing aspects of the air fryer is its versatility. It can handle a wide range of recipes, from crispy French fries and chicken wings to even baking cakes and cookies. This multipurpose nature means that the appliance can take the place of several others in your kitchen, streamlining your cooking routine.

The air fryer’s design has also played a significant role in its popularity. With sleek, modern aesthetics, these appliances are not just functional but also stylish. They can be a centerpiece on your countertop, blending in with contemporary kitchen decor.

Safety is another key factor that has contributed to the air fryer’s success. The non-stick surfaces and enclosed cooking chamber prevent oil splatters and burns, making it a safer option for home cooks. This has been particularly reassuring for parents who want to keep their kitchens free from hazards.

The convenience of the air fryer extends beyond its cooking capabilities. Many models come with accessories such as baskets, trays, and even built-in timers, enhancing the user experience. The ability to cook a variety of foods in one appliance has made meal prep easier and more efficient.

Moreover, the air fryer has spurred a wave of innovation in the culinary world. Chefs and home cooks alike are experimenting with new recipes that take advantage of the appliance’s capabilities. This has led to a surge in air fryer-friendly recipes online, offering endless inspiration for those looking to try something new.

As the air fryer continues to gain traction, manufacturers are responding with even more features and innovations. Smart technology, such as Bluetooth connectivity and app integration, allows users to control their appliances remotely and access a wealth of recipes. This integration with the digital age further solidifies the air fryer’s position as a must-have kitchen gadget.

The air fryer’s impact on the food industry extends beyond the home kitchen. It has influenced the way restaurants and fast-food chains prepare their meals, with some now offering air-fried options on their menus. This shift towards healthier alternatives is likely to continue as consumer demand for healthier food options grows.

In conclusion, the air fryer has become a game-changer because it offers a healthier, quicker, and more versatile cooking experience. Its ability to mimic the taste and texture of fried foods without the health drawbacks has made it a beloved appliance in kitchens worldwide. As technology continues to evolve, the air fryer is poised to become an even more integral part of our cooking habits.

The Automated Air Fryer Assembly Line: A Revolution in Production

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged not just as a gadget, but as a game-changer. Its unique ability to mimic deep-frying with minimal oil has won over health-conscious consumers and cooking enthusiasts alike. Now, this technological marvel is about to undergo a transformation with the advent of the automated air fryer assembly line. This innovation is not just a step forward in production; it’s a leap into the future of culinary efficiency.

The assembly line, a cornerstone of the manufacturing process, has seen countless iterations over the years. It’s the backbone of mass production, ensuring consistency and speed. The introduction of automation to the air fryer assembly line marks a significant shift, one that promises to redefine the way we think about kitchen appliances.

Precision Engineering Meets Culinary Craft

The heart of the automated air fryer assembly line lies in its precision engineering. Each component is meticulously designed to fit seamlessly into the production process. From the base to the heating element, every part is assembled with such precision that it’s hard to believe it’s not done by hand. The result is a unit that not only performs optimally but also looks and feels premium.

Robotic Precision and Flexibility

Robotic arms are the unsung heroes of this assembly line. They move with a dexterity that surpasses human capability, ensuring that each air fryer is assembled to the highest standards. These robots can handle tasks like placing electronic components, securing wires, and even testing the fryer’s functionality. Their flexibility means they can adapt to different models and configurations, making the line versatile and efficient.

Intelligent Integration and Real-Time Monitoring

The automation doesn’t stop at robotics; it extends to the integration of sophisticated software. This software manages the entire assembly process, from the arrival of raw materials to the final quality check. It monitors the line in real-time, adjusting parameters and alerting operators to any potential issues. This intelligent integration ensures that every air fryer that rolls off the line meets the exacting standards of the manufacturer.

Quality Control Without Compromise

One of the most significant advantages of an automated assembly line is the unparalleled level of quality control it offers. Each step of the production process is scrutinized by sensors and AI algorithms, ensuring that defects are caught early. This rigorous quality control not only guarantees that customers receive a flawless product but also minimizes the risk of recalls and warranty claims.

Energy Efficiency and Sustainability

An automated air fryer assembly line is not just about speed and quality; it’s also about sustainability. By automating the process, manufacturers can reduce energy consumption and waste. The line is designed to operate with minimal environmental impact, reflecting a commitment to sustainable practices that resonate with today’s environmentally conscious consumers.

Cost-Effectiveness and Scalability

The introduction of an automated assembly line also brings significant cost benefits. While the initial investment is substantial, the long-term savings in labor, material, and energy costs make it a financially sound decision. Moreover, the scalability of the line means that as demand grows, the production capacity can be easily expanded without a proportional increase in costs.

A New Era of Innovation

The automated air fryer assembly line is more than just a technological marvel; it’s the beginning of a new era in kitchen appliance manufacturing. It paves the way for further innovation, with the potential to integrate advanced features and functionalities that were once only dreams. This line is a testament to human ingenuity and the endless possibilities that lie at the intersection of technology and culinary art.

In the realm of kitchen appliances, the automated air fryer assembly line stands as a testament to modern manufacturing prowess. This line is not just a series of machines; it’s a symphony of precision and efficiency. Let’s delve into the key features that make this assembly line a game-changer.

The heart of the automated air fryer assembly line is the robotics. These robots are designed with the agility and precision needed to handle the delicate tasks of assembling an air fryer. They can pick up components with the utmost care, ensuring that each part is placed correctly and securely. Their ability to work tirelessly around the clock without fatigue is a significant advantage over human labor.

Precision machinery is another cornerstone of this assembly line. From the cutting and shaping of metal parts to the precise placement of electronic components, every step is executed with pinpoint accuracy. CNC machines and automated cutting tools ensure that the materials are processed to exact specifications, reducing waste and improving the overall quality of the product.

The integration of various systems is a key feature that sets this assembly line apart. It’s not just about having different machines; it’s about having them work together seamlessly. For instance, the assembly line might include a system for applying heat shrink tubing, which is then followed by a robotic arm that places the wires into the correct slots. This integration allows for a smooth flow of production, minimizing downtime and increasing throughput.

Quality control is woven into the fabric of the automated assembly line. Sensors and cameras are strategically placed throughout the line to monitor every stage of the manufacturing process. They can detect any deviations from the standard and trigger an immediate response, whether it’s a robotic rework station or an alert to the production manager. This ensures that only air fryers meeting the highest standards are released for packaging.

Energy efficiency is a critical aspect of the automated air fryer assembly line. Advanced lighting systems are used to illuminate the workspace, reducing energy consumption compared to traditional lighting. Additionally, the use of energy-efficient motors and automated systems that power down when not in use contribute to a more sustainable production process.

The design of the assembly line itself is a marvel of engineering. It’s not just about the machines; it’s about the space they occupy and how they interact with each other. The layout is optimized for efficiency, with conveyors and robotic arms moving products through the line with minimal distance and time. This design not only speeds up production but also reduces the risk of accidents and injuries.

Flexibility is a key feature that allows the assembly line to adapt to changes in product design or market demands. Modular components can be easily swapped out, and the line can be reconfigured to accommodate new models or features. This adaptability ensures that the assembly line can continue to produce top-quality air fryers as the industry evolves.

In terms of data collection and analysis, the automated air fryer assembly line is equipped with systems that gather vast amounts of data. This data is then used to optimize the production process, predict maintenance needs, and even inform product design. The ability to analyze this data in real-time provides insights that can lead to continuous improvement and innovation.

Lastly, the human element is not forgotten. While the assembly line is largely automated, there are still roles for skilled workers. These individuals are trained to oversee the line, troubleshoot issues, and maintain the equipment. Their expertise is invaluable in ensuring that the assembly line runs smoothly and efficiently.

In summary, the automated air fryer assembly line is a marvel of modern technology, combining robotics, precision machinery, integration, quality control, energy efficiency, design, flexibility, data analytics, and human oversight. It’s this combination of features that has made it a revolutionary force in the production of air fryers and a beacon of what’s possible in the world of kitchen appliance manufacturing.

In the world of manufacturing, efficiency and speed are king. The advent of automation has reshaped industries, and the automated air fryer assembly line is no exception. This innovative process offers a myriad of benefits that can significantly impact the bottom line and the quality of the final product. Let’s delve into the advantages of this streamlined approach.

1. Precision in Every Detail

Automation in the assembly line ensures that each component of the air fryer is placed with pinpoint accuracy. The use of robots and precision machinery guarantees that the assembly is consistent, eliminating the variability that can occur with manual labor. This level of precision is crucial in ensuring that every air fryer performs optimally, with the correct balance of parts and functions.

2. Reduced Cycle Times

One of the most immediate benefits of automation is the reduction in cycle times. With human workers, the assembly process can be time-consuming, with each step requiring attention and care. Automation, on the other hand, can complete tasks at a much faster pace. This not only increases output but also allows for shorter lead times, which is a significant advantage in today’s fast-paced market.

3. Enhanced Productivity

Automation does not just reduce the time it takes to produce air fryers; it also enhances overall productivity. By automating repetitive tasks, manufacturers can allocate human workers to more complex and value-added activities. This shift in labor allows for a more efficient use of human resources and can lead to the development of new products or improvements in existing ones.

4. Cost Savings Over Time

While the initial investment in an automated assembly line can be substantial, the long-term cost savings are substantial. Automation reduces the need for manual labor, which means fewer workers are required on the production floor. This not only cuts labor costs but also reduces the risk of workplace injuries and the associated costs of workers’ compensation claims.

5. Consistent Quality Control

Maintaining high quality standards is essential in the manufacturing of air fryers. Automation allows for rigorous quality control measures to be implemented throughout the assembly process. Sensors and AI systems can monitor the assembly line in real-time, detecting any deviations from the standard and triggering corrective actions immediately. This ensures that only air fryers meeting strict quality criteria are released for sale.

6. Scalability and Flexibility

An automated assembly line is designed to be scalable, which means it can be easily adapted to produce different models or variations of air fryers. This flexibility is crucial in a market that is constantly evolving and requires manufacturers to respond quickly to consumer demands. The ability to switch between models with minimal downtime or retooling is a significant advantage.

7. Reduced Waste

Manual assembly processes often result in waste due to errors, overproduction, or scrap materials. Automation minimizes waste by reducing the likelihood of errors and optimizing material usage. Robots can be programmed to handle materials with precision, ensuring that every part is used efficiently, which is both cost-effective and environmentally friendly.

8. Continuous Improvement

Automation encourages a culture of continuous improvement. With data collection and analysis capabilities integrated into the assembly line, manufacturers can continuously refine their processes. This data-driven approach allows for the identification of bottlenecks, inefficiencies, and opportunities for further optimization.

9. Enhanced Safety

Safety is a paramount concern in any manufacturing environment. Automation can significantly reduce the risk of workplace accidents by removing humans from hazardous tasks. Robots can handle high-temperature components, toxic materials, or repetitive strain tasks that could otherwise lead to injury.

10. Global Competitiveness

Finally, the adoption of an automated assembly line can boost a company’s global competitiveness. In today’s interconnected world, the ability to produce high-quality products at a competitive price is essential. An automated assembly line can help manufacturers achieve these goals, ensuring they remain viable in the global marketplace.

In summary, the benefits of automation in the assembly of air fryers are numerous and far-reaching. From precision and efficiency to cost savings and safety, the automated assembly line is a game-changer that is reshaping the future of manufacturing.

In the world of manufacturing, quality control and consistency are the cornerstones of a successful product. When it comes to the automated air fryer assembly line, these principles are paramount. Here’s a closer look at how these aspects are achieved:

The meticulous attention to detail begins with the selection of materials. High-quality, durable components are chosen to ensure that each air fryer can withstand the rigors of daily use. From the stainless steel exterior to the heat-resistant interior, every part is carefully selected to meet the stringent standards set by the industry.

Robotic precision is the heartbeat of the assembly line. Robots, equipped with advanced sensors and guided by intricate software, work in harmony to assemble each air fryer with pinpoint accuracy. This level of precision minimizes the risk of human error, which can lead to defective products or inconsistencies in performance.

The integration of AI and machine learning further enhances quality control. These intelligent systems analyze data in real-time, learning from each assembly process to optimize efficiency and identify potential issues before they arise. By continuously refining their algorithms, they ensure that every air fryer produced meets the highest quality standards.

Quality checks are woven into the very fabric of the assembly line. Automated testing stations are strategically placed to perform a variety of checks throughout the production process. These include electrical safety tests, functionality checks, and thermal performance evaluations. Any air fryer that fails to meet the specified criteria is immediately identified and removed from the line, preventing its release into the market.

Consistency is maintained through the use of standardized processes. Every step of the assembly is meticulously documented, and operators are trained to adhere to these protocols without deviation. This ensures that each air fryer is built using the same methods and with the same level of care, resulting in a consistent product that consumers can rely on.

Moreover, the assembly line is designed with redundancy in mind. In the event of a failure in one system, another takes over to ensure that the production process continues uninterrupted. This redundancy not only maintains quality but also minimizes downtime, keeping the assembly line running efficiently.

Regular maintenance is a critical component of quality control. The assembly line is kept in top condition through a rigorous maintenance schedule. This includes cleaning, lubricating, and inspecting all equipment to prevent wear and tear that could compromise the quality of the final product.

Employee training is another key factor in ensuring quality and consistency. Workers are trained not only on the technical aspects of assembly but also on the importance of their role in the overall quality process. This emphasis on continuous learning helps to foster a culture of excellence and accountability.

Lastly, the feedback loop is crucial. After the air fryers are released to the market, customer feedback is collected and analyzed. This information is then used to further refine the assembly process, ensuring that any issues are addressed promptly and that future products are even better than their predecessors.

In conclusion, the automated air fryer assembly line is a marvel of modern manufacturing, where quality control and consistency are paramount. Through the use of advanced technology, meticulous processes, and a focus on continuous improvement, each air fryer that rolls off the line is a testament to the dedication to excellence in production.

The shift towards sustainability has become a cornerstone in the manufacturing sector, and the automated air fryer assembly line is no exception. Here’s a deep dive into how this technology impacts the environment and promotes sustainability:

In the realm of manufacturing, the traditional assembly line has often been a source of significant environmental strain. However, the automated air fryer assembly line represents a significant leap forward in this regard. By reducing waste, minimizing energy consumption, and employing eco-friendly materials, these assembly lines are redefining what it means to produce kitchen appliances sustainably.

One of the most profound impacts of the automated assembly line is the reduction in material waste. Unlike manual processes, which can result in a higher percentage of scrap materials, the automated line is designed to use materials efficiently. Advanced software and sensors ensure that every piece is cut, shaped, and assembled with precision, minimizing the excess material that ends up in landfills.

Energy consumption is another critical area where the automated air fryer assembly line shines. Traditional assembly lines often require a substantial amount of power to run the various machines and maintain the necessary temperature and pressure. In contrast, automated lines are optimized for energy efficiency. They use smart systems that adjust power usage based on demand, ensuring that energy is conserved without compromising production speed.

Moreover, the use of renewable energy sources is becoming increasingly common in these assembly lines. Solar panels and wind turbines can be integrated into the manufacturing facility, providing a clean and sustainable energy supply. This not only reduces the carbon footprint but also sets a precedent for other industries to follow suit.

The components used in the automated assembly line are also a testament to sustainability efforts. Recycled materials are increasingly being used in the construction of machinery and assembly equipment. These materials are not only cost-effective but also contribute to the reduction of environmental impact. The longevity of these components is also a factor; they are designed to last, reducing the need for frequent replacements and further cutting down on waste.

Water usage is another area where the automated air fryer assembly line excels. Advanced systems are employed to recycle and reuse water, minimizing the amount of fresh water required for the manufacturing process. This is particularly important in regions where water scarcity is a concern.

The environmental impact extends beyond the manufacturing process. The end products themselves are designed with sustainability in mind. The air fryers produced on these automated lines are often equipped with features that promote energy efficiency and reduce waste at home. For instance, they consume less electricity than traditional fryers and can be used to prepare a variety of dishes, reducing the need for multiple appliances.

In terms of emissions, the automated assembly line contributes to a cleaner environment. By reducing energy consumption and waste, these lines produce fewer greenhouse gases. Additionally, the use of eco-friendly materials and the reduction in packaging can further decrease the carbon footprint associated with the product lifecycle.

The impact of the automated air fryer assembly line on sustainability is also felt in the supply chain. Companies are increasingly choosing suppliers that adhere to sustainable practices, ensuring that the materials used in the assembly process are ethically sourced and processed.

Lastly, the automation of the assembly line has a ripple effect on the overall sustainability of the product. It allows for better tracking and tracing of materials, which is crucial for managing the environmental impact throughout the product’s lifecycle. This traceability also enables companies to make informed decisions about the sourcing and production of their products, ensuring that they are in line with environmental standards.

In conclusion, the automated air fryer assembly line is not just a technological advancement; it’s a step towards a more sustainable future. By focusing on efficiency, reducing waste, and employing eco-friendly practices, these assembly lines are setting a new standard for the manufacturing industry. As consumers become more environmentally conscious, the demand for such sustainable products will only continue to grow, encouraging further innovation and commitment to sustainability.

The air fryer has become a staple in modern kitchens, offering a healthier alternative to traditional frying methods. As technology advances, the design and functionality of these appliances continue to evolve, pushing the boundaries of what we expect from our kitchen gadgets. Here’s a closer look at some of the innovative features shaping the future of air fryer design and functionality:

In recent years, air fryers have moved beyond the basic functionality of crispy, low-fat fries. Today’s models are equipped with a variety of smart features that cater to the diverse needs of cooks. From precise temperature control to programmable cooking times, these innovations are making air fryers a versatile tool in the kitchen.

One standout feature is the inclusion of preset cooking modes for a wide range of foods. Whether you’re cooking chicken, vegetables, or even desserts, many modern air fryers have a dedicated setting to ensure optimal results. This level of customization allows for greater flexibility and convenience, as users can simply select the mode that suits their dish without having to adjust settings manually.

The integration of smart technology has also brought about significant changes. Some air fryers can be controlled via smartphones or tablets, allowing users to monitor and adjust cooking times and temperatures remotely. This connectivity not only adds a layer of convenience but also enables users to start their meal preparation even before they arrive home.

Design-wise, air fryers are becoming sleeker and more integrated into kitchen aesthetics. The days of bulky, boxy appliances are fading, as manufacturers focus on creating compact, space-saving devices that blend seamlessly with other kitchenware. Modern air fryers often feature sleek, rounded designs and are available in a range of colors to match different kitchen decors.

Another innovation is the use of non-stick surfaces that are not only durable but also easy to clean. These surfaces ensure that food doesn’t stick to the basket, making it easier to remove and clean after cooking. Some models even have self-cleaning functions that use steam to loosen and remove residue, further reducing the time and effort required to maintain the appliance.

Health-conscious consumers are also benefiting from new features that provide nutritional information. Some air fryers can calculate the calorie count of the food being cooked, offering a healthier option without sacrificing taste. This type of transparency is becoming increasingly important as people look for ways to make informed choices about their diet.

The rise of sous-vide cooking has also influenced air fryer design. Many new models now offer vacuum sealing capabilities, allowing for precise temperature control and even cooking. This feature has opened up a world of culinary possibilities, enabling users to achieve restaurant-quality results at home.

Safety features have also been enhanced. Modern air fryers come with overheat protection, auto shut-off functions, and cool-touch handles to prevent accidents. These features are crucial in ensuring that users can cook with peace of mind, knowing that their safety is a top priority.

Innovation in air fryer design and functionality doesn’t stop at the appliance itself. Accessories are also being developed to expand the cooking possibilities. From air fryer lids to attachments that can be used for grilling or baking, these additions allow users to get more out of their air fryers and explore new cooking techniques.

As the air fryer market continues to grow, we can expect to see even more innovative features that cater to the evolving tastes and needs of consumers. From advanced temperature sensors to interactive cooking apps, the future of air fryers looks to be as diverse and exciting as the meals they help us create.

The air fryer has emerged as a game-changer in the kitchen appliance industry, transforming the way we approach cooking. It’s not just a gadget; it’s a revolution that has sparked a new era of culinary innovation. Once confined to the realm of deep-frying, the air fryer now claims a spot in health-conscious households, promising delicious, crispy foods with significantly less oil. The technology behind this marvel has evolved, and it’s fascinating to see how it has reshaped our cooking habits.

As the air fryer gained popularity, manufacturers began to refine the design, focusing on ease of use and efficiency. The compact size and intuitive interfaces made it a hit with busy professionals and families alike. No longer do we have to worry about the hassle of deep frying or the cleanup that follows. The air fryer’s ability to mimic the texture of fried food without the guilt has been a savior for those looking to maintain a balanced diet.

One of the most remarkable aspects of the air fryer’s rise is its versatility. It’s no longer just for French fries and onion rings. Chefs and home cooks alike have embraced the appliance to create an array of dishes, from crispy chicken wings to tender roasted vegetables. The ability to cook a variety of foods in a single appliance has made the air fryer a staple in modern kitchens.

The convenience factor cannot be overstated. With an air fryer, there’s no need to monitor the oil temperature, and the cooking time is often shorter than traditional frying methods. This means less time spent in the kitchen and more time enjoying the fruits of your culinary labor. The appliance also boasts a variety of settings, allowing for different cooking temperatures and times, which means you can experiment with recipes and find the perfect setting for each dish.

The technology behind the air fryer is equally impressive. The key lies in the fan that circulates hot air around the food, creating a crispy outer layer while cooking it from the inside. This process, known as “air frying,” is more energy-efficient than traditional deep frying and results in a healthier option. The appliance’s ability to achieve a golden-brown finish without excess oil has been a game-changer for those looking to indulge in their favorite fried foods without the added calories.

Moreover, the air fryer has become a symbol of innovation in kitchen appliances. Manufacturers have continued to push the boundaries, introducing features like removable baskets for easy cleaning, non-stick surfaces that last, and even digital interfaces that allow for precise temperature control. These advancements have not only made the air fryer a more practical cooking tool but also a stylish addition to any kitchen.

The impact of the air fryer on the food industry has been significant. Fast-food chains and casual dining establishments have taken notice, offering air-fried menu items that mimic the taste and texture of fried foods. This has opened up a new market segment and has encouraged the development of healthier alternatives to traditional fried fare.

The air fryer’s success has also influenced consumer behavior. Health-conscious consumers are more likely to purchase appliances that align with their dietary goals, and the air fryer has become a beacon for those looking to reduce their oil intake without sacrificing flavor. Additionally, the appliance’s ease of use has made it a staple for families, as it’s simple enough for children to operate while providing a level of convenience that busy parents appreciate.

As the air fryer continues to evolve, it’s clear that it’s more than just a cooking tool; it’s a lifestyle choice. The appliance has empowered consumers to cook healthier, more diverse meals at home, all while enjoying the same level of satisfaction as traditional fried foods. The air fryer’s impact on the kitchen appliance market is undeniable, and its continued innovation promises to bring even more exciting culinary possibilities to the table.

In the ever-evolving landscape of kitchen appliances, the future of automated cooking appliances is poised to reshape how we interact with our kitchens. From the rise of smart cookers to the integration of AI, here are some predictions and speculations on what lies ahead.

The integration of IoT (Internet of Things) in kitchen appliances is set to become more sophisticated, allowing for seamless communication between devices. Imagine a scenario where your refrigerator can suggest recipes based on the ingredients you have, and your oven adjusts its settings automatically to ensure optimal cooking conditions. This interconnectedness promises a more personalized and efficient cooking experience.

Voice assistants and AI are likely to play a more significant role in the kitchen. As these technologies become more advanced, they will not only follow commands but also anticipate needs. A future where your kitchen appliances can learn your preferences and cooking habits, adjusting settings accordingly, is not far-fetched. This could lead to a more hands-off approach to cooking, freeing up time for other activities.

The concept of modular kitchen appliances is gaining traction. These are devices that can be customized and upgraded, much like a smartphone. Users could opt for specific functionalities based on their needs, and as technology advances, they could add new features without replacing the entire unit. This approach not only promotes longevity but also allows for a kitchen that evolves with the homeowner’s lifestyle.

Sustainability will continue to be a driving force in appliance design. As awareness of environmental issues grows, manufacturers are under pressure to produce appliances that are energy-efficient and have a lower carbon footprint. We might see appliances that are not only eco-friendly but also made from recycled materials, emphasizing a circular economy.

Health and wellness are at the forefront of consumer interests, and this trend is expected to influence the future of cooking appliances. Devices that can track nutritional content, provide healthy cooking options, and even suggest meal plans based on dietary restrictions will become more common. The kitchen of the future could be a place where health-conscious cooking is as easy as pressing a button.

The rise of virtual and augmented reality (VR/AR) could revolutionize the way we interact with our appliances. Imagine using VR to simulate a cooking class right in your kitchen, where you can learn new techniques and recipes without leaving home. AR could overlay digital instructions onto your countertop, guiding you through complex recipes with ease.

Customization is another trend that’s likely to grow. With the ability to print kitchenware, we could see a future where every kitchen has its unique set of tools and appliances, tailored to the specific needs and preferences of the homeowner. This could lead to a more personalized and creative cooking experience.

Innovation in cooking technology might also bring about the development of new types of appliances. For example, we could see the emergence of appliances that focus on specific cuisines, such as a device designed specifically for making sushi or a machine that can replicate the flavor and texture of traditional wood-fired pizzas.

The future of automated cooking appliances also hinges on the development of new materials and cooking methods. For instance, advancements in heat-conducting materials could lead to appliances that cook faster and more evenly, reducing energy consumption and improving food quality.

Lastly, the cultural exchange of cooking techniques and ingredients is likely to influence the future of kitchen appliances. As people become more connected globally, appliances may incorporate features that cater to a wider range of international cuisines, making diverse cooking styles more accessible to everyone.

The kitchen of the future is not just a place where food is prepared; it’s a hub of innovation, sustainability, and personalization. As technology continues to advance, the automated cooking appliances we use will not only enhance our culinary experiences but also reflect our values and aspirations as a society.