The Arctic Grade Waffle Maker sticks out in the kitchen equipment market for its first-rate performance and overall performance. With its advanced thermal technology, it ensures even heating and perfect waffle shapes, reducing cooking time and electricity waste. Its innovative design, presenting a smart temperature control gadget and non-stick surfaces, ensures a problem-free and healthy cooking enjoy. this versatile equipment is not just for waffles; it is able to additionally create a selection of shapes, making it a ought to-have for any kitchen seeking efficient and surefire cooking solutions.

The OEM kitchen appliance marketplace is experiencing fast boom, driven by way of the call for for wise, power-green, and

merchandise. OEM producers are facing both possibilities and challenges, which includes fierce logo competition, growing uncooked material costs, and the need for continuous technological innovation. To thrive, those producers are specializing in person experience-pushed product innovation, incorporating smart capabilities, humanized layout, and fashionable aesthetics. they are also emphasizing environmental responsibility and after-income carrier to beautify logo reputation. in spite of these demanding situations, the market’s potential for expansion is considerable, with a international trend closer to differentiated development and coverage assist from governments.

the commercial waffle maker industry has surged, with demand fueling increase for manufacturers. innovations in product design, like multifunctional waffle irons and clever controls, have turn out to be critical for producers to ensure performance. As competition intensifies and market needs diversify, factories are focused on smart technology, customization, and environmental compliance to meet customer and ecological requirements. The emphasis is on enhancing product performance whilst navigating the challenges of market saturation and regulatory requirements.

Ningbo’s kitchen equipment provider has outstanding itself within the marketplace, attaining monthly sales exceeding 10,000 gadgets. This achievement is attributed to their progressive product improvement, marketplace acumen, and strong brand constructing. With a numerous variety of

kitchen home equipment, which includes clever and power-efficient fashions, Ningbo suppliers lead the enterprise trend, catering to various client wishes. Their strategic attention on product customization, environmental sustainability, and green deliver chain management has solidified their role as a leading kitchen equipment dealer, using market growth and innovation.

The kitchen appliance enterprise in China is experiencing a surge in innovation, driven by evolving patron demands and technological improvements. OEM factories in the jap areas, mainly around the Yangtze and Pearl River deltas, are at the leading edge, taking advantage of a sturdy supply chain,

manufacturing, and favorable rules. these factories are responding unexpectedly to market tendencies, specializing in smart, fitness-conscious, and multi-functional kitchen appliances, whilst additionally embracing customization and more desirable after-sales services to supply a superior consumer enjoy.

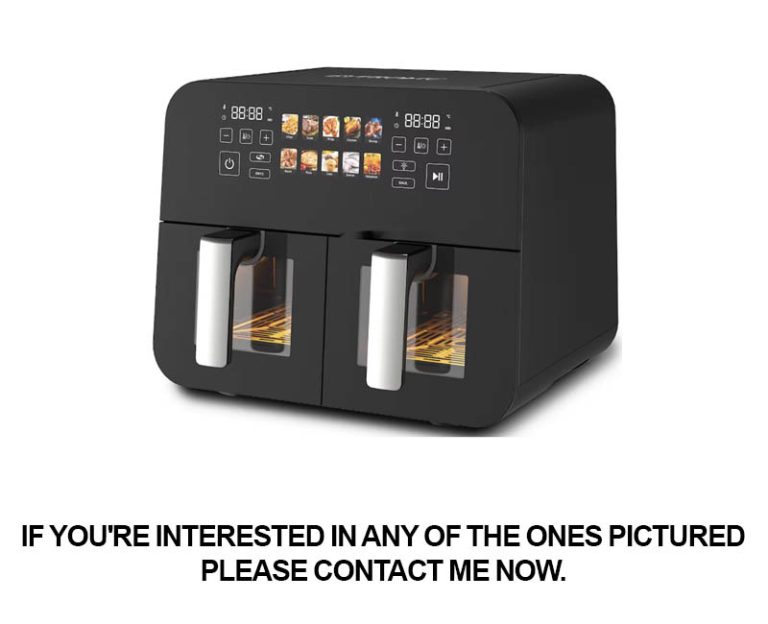

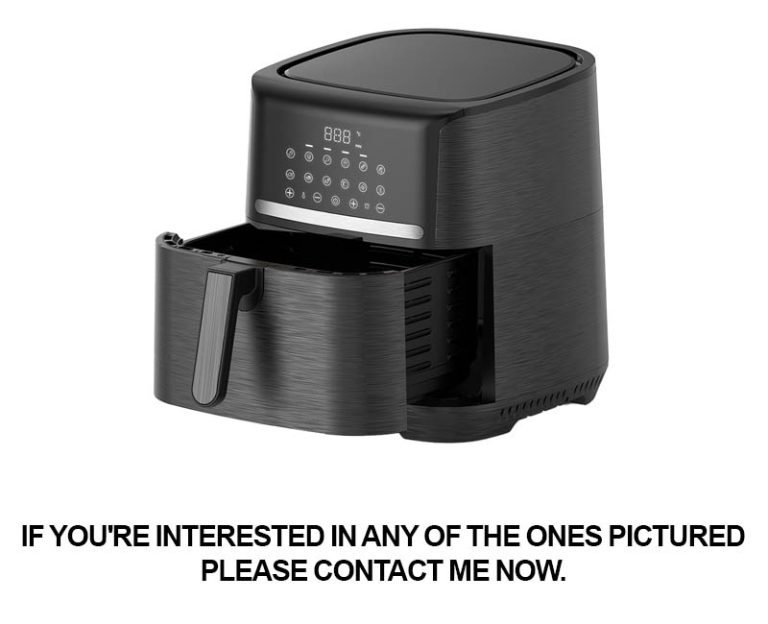

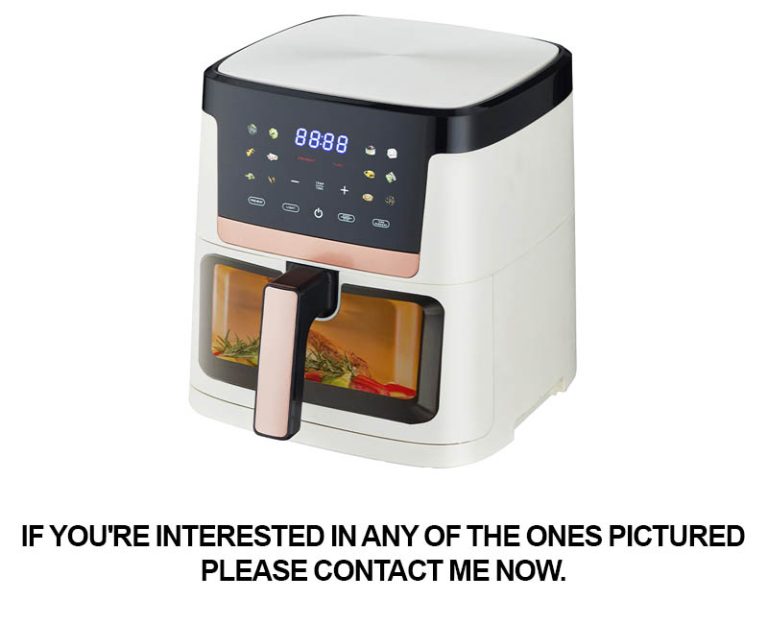

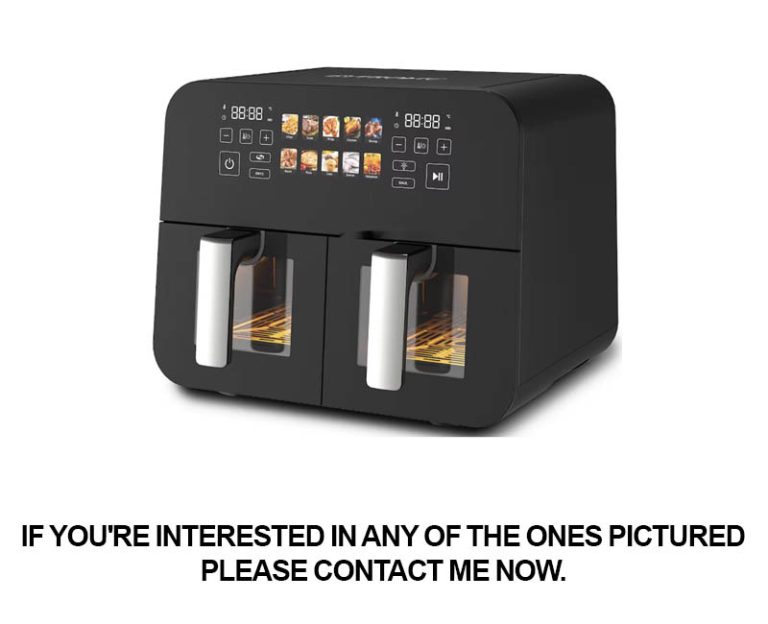

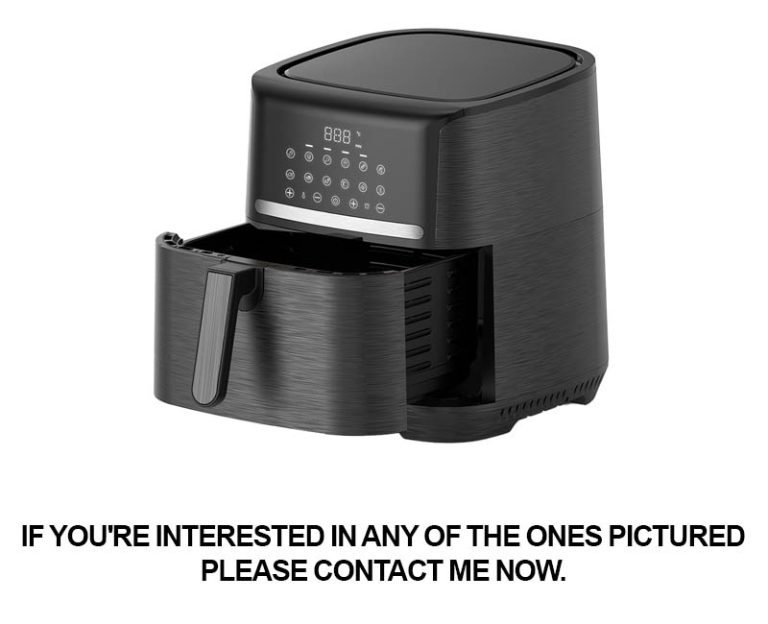

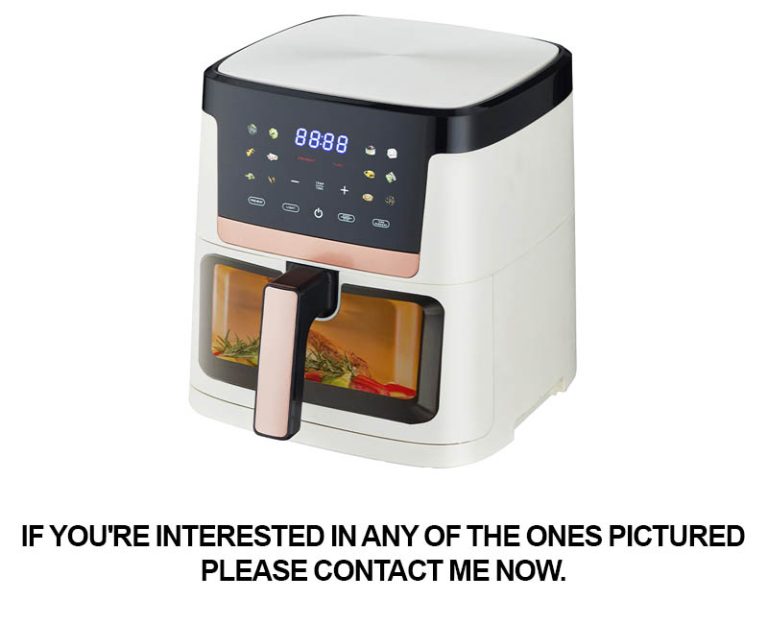

The CE-licensed air fryer OEM marketplace is experiencing rapid growth, driven through consumer demand for healthier cooking methods. producers, like OEMs, are focusing on innovation to satisfy these needs. Key traits encompass multifunctional home equipment which can air fry, bake, and steam, clever functions for far off manipulate and recipe matching, and the usage of

substances. To thrive, OEMs ought to adapt to market needs, optimize supply chains, and put money into continuous R&D, ensuring their products meet CE requirements and offer a aggressive facet within the marketplace.

The EAC compliant sandwich maker manufacturing facility is vital for groups looking for to enter the Eurasian economic Union market. those producers must adhere to stringent health, protection, and environmental standards, as dictated by means of EAC certification. Key capabilities encompass ensuring product pleasant, criminal market access, and enhancing emblem recognition. but, demanding situations encompass certification expenses, technical necessities, and time investments. To thrive, businesses ought to optimize product layout, spend money on best control structures, and live abreast of market traits to maintain competitiveness.

The air fryer market is experiencing enormous boom, pushed with the aid of the upward push of a healthy way of life. Low MOQ air fryer producers are at the leading edge, capitalizing on patron call for for low-fat, handy cooking answers. those manufacturers are innovating with various product strains, integrating smart era, and that specialize in strength efficiency and environmental sustainability. no matter marketplace competition and challenges like material value fluctuations, these manufacturers are expanding their market share with the aid of leveraging e-trade and concentrated on niche segments. With technological advancements and a international expansion method, low MOQ air fryer manufacturers are poised to guide the air fryer market’s dynamic growth.

as the customizable contact grill OEM marketplace surges, innovative techniques are being hired to obtain a outstanding 30% value discount in kitchen home equipment like baking plates. via leveraging technology, including light-weight alloys and automation, producers are cutting material and exertions fees. moreover, supply chain optimization and streamlined designs make a contribution to the affordability of these merchandise. those advancements now not most effective gain the appliance industry however additionally resonate with consumers in bustling towns like positive metropolis, who seek each fine and fee in their kitchen answers.

The excessive-volume juicer production line, boasting rapid reaction and efficiency, is a market darling within the city. With its ability to churn out lots of devices every day and a forty eight-hour quoting commitment, it enhances purchaser enjoy and outpaces competitors. This approach, blended with the equipment enterprise’s embrace of automation and smart generation, guarantees that both productivity and purchaser delight are maximized, making it a high desire for both producers and consumers alike.