Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary landscape evolves, so does the technology behind kitchen appliances. Among these innovations, commercial air fryers have emerged as a game-changer, promising healthier cooking methods while delivering delicious results. This surge in popularity has spurred a wave of creativity and technological advancements within the commercial air fryer industry. Let’s delve into the fascinating journey of these appliances and their impact on the market.

The commercial air fryer market has surged in popularity, becoming a cornerstone in the kitchen appliance industry. These innovative cooking devices have not only captured the interest of culinary professionals but have also made their way into the homes of health-conscious consumers. Let’s dive into the fascinating world of commercial air fryers and understand what makes them a game-changer in the market.

With the growing awareness of health and wellness, consumers are increasingly looking for cooking methods that offer delicious flavors without the guilt. Commercial air fryers have stepped in to fill this void, providing a solution that is both convenient and nutritious. These appliances use a circulating hot air process to cook food, significantly reducing the amount of oil needed compared to traditional frying methods. This has made them a favorite among restaurants, cafes, and even fast-food chains looking to offer healthier options to their patrons.

The market for commercial air fryers has seen a surge in demand due to several factors. Firstly, the health benefits they offer are undeniable, as they allow for the preparation of crispy, golden foods with minimal oil. This aligns perfectly with the current dietary trends that emphasize lower fat content and reduced calorie intake. Secondly, the convenience of air frying is hard to ignore. The cooking process is much quicker than traditional frying, and the cleanup is a breeze since the appliance does not require a deep fryer.

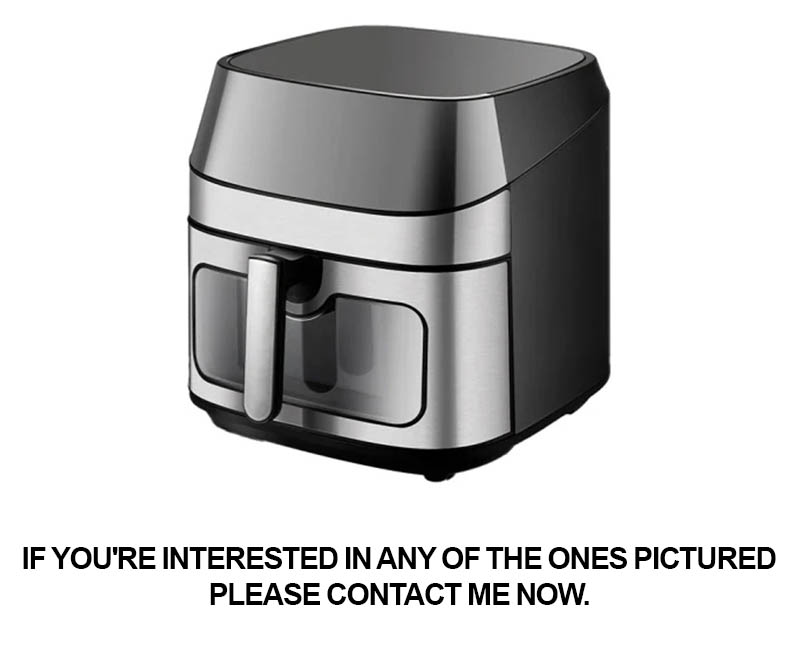

Commercial air fryer factories have responded to this demand by producing a variety of models, each tailored to different commercial needs. From countertop models that are perfect for smaller establishments like cafes to larger, industrial-grade units designed for busy kitchens in restaurants and hotels, there’s an air fryer to suit every operation. These factories have also invested in research and development to create air fryers that not only meet the technical requirements of the market but also exceed the expectations of end-users.

One of the key aspects of commercial air fryer design is the focus on efficiency and performance. These appliances are built to handle high volumes of food quickly and consistently, ensuring that food is cooked to perfection each time. The ability to adjust cooking temperatures and times has become a standard feature, allowing chefs and cooks to fine-tune their recipes to achieve the perfect texture and flavor.

Another significant trend in the commercial air fryer market is the integration of smart technology. Many modern models come with digital controls, timers, and even apps that allow operators to monitor and control the cooking process remotely. This level of connectivity not only enhances convenience but also allows for better inventory management and energy conservation.

Innovation in the commercial air fryer sector is not limited to technology; it also extends to the materials used in their construction. Eco-friendly and durable materials are becoming more prevalent, ensuring that these appliances are not only functional but also sustainable. This commitment to sustainability resonates with a consumer base that values the environmental impact of their purchases.

While the market for commercial air fryers is booming, there are challenges to overcome. One of the primary challenges is the need for ongoing innovation to keep up with the rapidly changing consumer preferences and dietary trends. Additionally, ensuring that these appliances meet the strict safety and quality standards required by commercial kitchens is a constant priority for manufacturers.

Looking ahead, the commercial air fryer market is poised for continued growth. The rise of health consciousness, combined with technological advancements, is expected to drive the market forward. There is also an opportunity for manufacturers to expand their product lines to include accessories and add-ons that further enhance the cooking experience, such as temperature probes and food dehydrators.

In conclusion, the commercial air fryer market is a dynamic and exciting space that is shaping the future of commercial cooking. With its health benefits, convenience, and technological advancements, it’s clear why these appliances are becoming a staple in kitchens worldwide. As consumer demands evolve, so too will the offerings from commercial air fryer factories, ensuring that this trend continues to cook up a storm.

Commercial air fryer factories are at the forefront of culinary innovation, pushing the boundaries of what traditional fryers can offer. These factories are not just manufacturing appliances; they are crafting the future of kitchen technology. Here’s a glimpse into the innovative designs that have been transforming the commercial air fryer market.

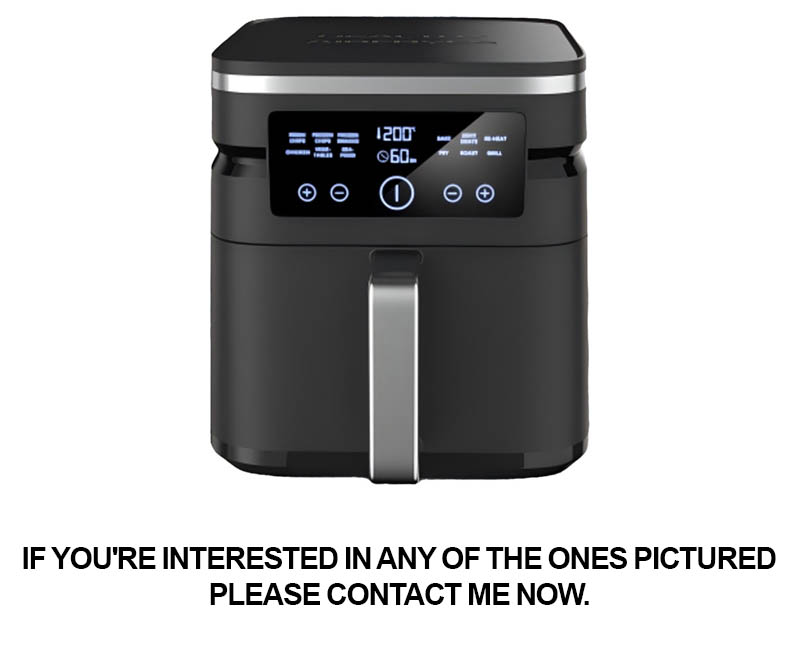

Intelligent Cooking Systems: Modern commercial air fryers are equipped with intelligent cooking systems that allow for precise temperature and time control. These systems are designed to mimic the perfect frying experience of traditional deep fryers but with significantly less oil. Sensors and software algorithms work in tandem to ensure that each batch of food is cooked to perfection, with consistent results every time.

Multi-Functional Capabilities: The latest designs in commercial air fryer factories are moving beyond just frying. Many models now come with additional functions such as roasting, baking, and even dehydrating. This versatility means that a single appliance can replace multiple conventional kitchen tools, saving space and reducing the complexity of food preparation.

Energy Efficiency: As sustainability becomes a crucial factor in commercial operations, air fryer factories are focusing on energy efficiency. Newer models are engineered to use less power while still maintaining high cooking temperatures. Some even feature eco modes that automatically adjust cooking times and temperatures to minimize energy consumption.

User-Friendly Interfaces: The user interfaces of commercial air fryers have evolved to be more intuitive and accessible. Touchscreen displays, digital timers, and programmable settings are now standard features. These interfaces make it easier for chefs and kitchen staff to operate the fryers without extensive training, leading to increased productivity.

Customizable Cooking Programs: To cater to a wide range of recipes and preferences, commercial air fryer factories are offering customizable cooking programs. These programs allow users to adjust settings for different types of food, ensuring that everything from French fries to chicken wings is cooked to the ideal crispness and texture.

Safety Features: Safety is a paramount concern in commercial kitchens, and air fryer factories are incorporating advanced safety features into their designs. Overheat protection, auto shut-off mechanisms, and childproof locks are just a few of the safety measures that are now standard in modern commercial air fryers.

Space-Saving Design: Commercial kitchens are often crowded and space is at a premium. Air fryer factories are addressing this need by designing compact and space-saving fryers. Some models are designed to stack or are modular, allowing them to be arranged in a way that maximizes counter space.

Custom Branding and Customization: Recognizing the importance of brand identity in the commercial market, air fryer factories are offering customization options. This includes the ability to brand the fryers with a company’s logo or design fryers with specific features that align with a brand’s culinary philosophy.

Durability and Maintenance: The durability of the equipment is crucial in a busy commercial kitchen. Air fryer factories are focusing on materials and construction that can withstand the rigors of daily use. Additionally, many of these fryers are designed with easy-to-clean surfaces and removable parts for simplified maintenance.

Integration with Smart Kitchen Systems: As kitchens become more connected, commercial air fryers are being designed to integrate with smart kitchen systems. This means they can be controlled remotely, monitored for energy usage, and even programmed to start cooking at specific times, all through a centralized kitchen management system.

The innovations in commercial air fryer factories reflect a commitment to efficiency, safety, and convenience. As these fryers continue to evolve, they are set to become an indispensable part of modern commercial kitchens worldwide.

In the ever-evolving landscape of the commercial air fryer market, understanding the latest trends and consumer demands is crucial for manufacturers and retailers alike. Here’s a closer look at what’s shaping the industry:

The surge in health consciousness has led to a significant increase in demand for healthier cooking methods. Consumers are seeking alternatives to deep-frying, which is often associated with higher levels of unhealthy fats. This shift has propelled the growth of commercial air fryers, as they offer a healthier way to enjoy fried foods with less oil.

One notable trend is the integration of smart technology in commercial air fryers. These appliances are becoming more connected, allowing users to monitor and control their cooking processes remotely via smartphones or tablets. This tech-savvy approach not only enhances convenience but also caters to the tech-savvy generation that values efficiency and control over their kitchen appliances.

Eco-friendly and sustainable practices are also gaining traction in the market. Consumers are increasingly looking for products that align with their environmental values. As a result, commercial air fryer factories are focusing on energy-efficient designs and materials that are recyclable or biodegradable.

Customization is another key trend, with consumers wanting appliances that can cater to a variety of cooking styles and preferences. This has led to the development of air fryers with adjustable temperature settings, various cooking modes, and even attachments for baking, roasting, and grilling. The ability to offer a versatile cooking experience is becoming a major selling point for manufacturers.

The demand for commercial air fryers in foodservice industries is soaring. Restaurants, cafes, and fast-casual chains are adopting these appliances to offer healthier menu options to their customers. The compact size and efficiency of commercial air fryers make them ideal for limited kitchen spaces, and their ability to cook a large volume of food quickly is a significant advantage.

Health certifications and endorsements are becoming more prevalent in the market. With the rise of health-conscious consumers, certifications from reputable health organizations can significantly boost sales. Manufacturers are keen to highlight any health claims associated with their products, such as low-calorie, low-fat, or gluten-free options.

In the wake of the pandemic, there has been a heightened focus on safety and hygiene. Commercial air fryers that can be easily cleaned and sanitized are in high demand. Features like removable parts, non-stick surfaces, and self-cleaning functions are becoming standard in new models.

The global market for commercial air fryers is witnessing a surge in cross-border collaborations. Brands are seeking to expand their reach by partnering with international distributors and suppliers. This globalization is not only opening up new markets but also fostering innovation through the sharing of ideas and technologies.

As the market continues to grow, there’s a rising demand for educational content. Consumers are looking for resources that can help them understand the benefits of air frying and how to use these appliances effectively. This has led to an increase in online tutorials, cooking classes, and recipe books that feature air fryer-friendly dishes.

The rise of social media influencers has also had a profound impact on the commercial air fryer market. These influencers often showcase their favorite recipes and cooking techniques using air fryers, influencing consumer purchasing decisions. Manufacturers are capitalizing on this trend by collaborating with influencers to create buzz and drive sales.

Lastly, the market is witnessing a trend towards healthier and more diverse ingredients. As consumers become more adventurous with their food choices, there’s a growing interest in international cuisines and unique flavors. This trend is prompting commercial air fryer factories to develop appliances that can handle a wider range of ingredients and cooking methods, further expanding the appeal of air fryers in both domestic and commercial settings.

In the realm of commercial air fryer production, technology has become an indispensable ally, driving innovation and efficiency. From the design phase to the final assembly, the integration of advanced tech has transformed the landscape of air fryer manufacturing.

The evolution of smart sensors has been particularly transformative. These sensors, capable of monitoring temperature and oil levels with precision, ensure that each air fryer operates at optimal conditions. This not only extends the life of the fryer but also guarantees consistent results for the end-user. The ability to maintain a precise heat level is crucial for achieving that perfect golden-brown finish on fried foods without the excess oil typically found in traditional fryers.

Automation has revolutionized the assembly line process. Once a labor-intensive task, the manufacturing of air fryers now involves robotic arms and precision machinery that can assemble components with unmatched speed and accuracy. This not only reduces production time but also minimizes the risk of human error. The integration of robotics has allowed for the creation of more complex and sophisticated fryer models that were once impossible to produce manually.

Energy efficiency is a growing concern, and technology has stepped in to address this. Modern air fryers are designed with energy-saving features that not only reduce operational costs for businesses but also contribute to a greener planet. The use of energy-efficient motors and smart controls ensures that the fryers use less electricity while still delivering the desired cooking performance.

In terms of materials, technological advancements have led to the development of new, durable, and non-toxic components. For instance, the use of high-quality stainless steel for exterior shells not only enhances the longevity of the fryer but also provides a sleek and hygienic surface that is easy to clean. Additionally, the adoption of BPA-free plastics for internal parts ensures that there is no risk of harmful chemicals leaching into the food.

The integration of connectivity features has also become a significant trend. Air fryers with Wi-Fi capabilities allow users to control and monitor their fryers remotely via smartphones or tablets. This technology not only adds convenience but also opens up new possibilities for data collection and analysis. Manufacturers can gather insights into usage patterns, which can inform future product development and marketing strategies.

Customization is another area where technology plays a crucial role. Through the use of 3D printing and advanced CAD software, manufacturers can create prototypes and test new designs quickly and cost-effectively. This iterative process allows for the creation of fryers that are tailored to specific market needs and consumer preferences.

Safety features have also seen significant advancements. Modern air fryers come equipped with overheat protection, auto shut-off functions, and child safety locks. These features are not only legally required in many markets but also provide peace of mind to consumers who are looking for a safe cooking solution.

In the realm of marketing and consumer engagement, technology has enabled the use of virtual reality (VR) and augmented reality (AR) to showcase the capabilities of air fryers. Consumers can experience the cooking process firsthand without even owning the product, which can be a powerful tool in the sales process.

As technology continues to evolve, so too does the potential for air fryer production. The future holds the promise of even more efficient and intelligent fryers that not only save time and money but also provide a healthier cooking alternative. The role of technology in air fryer production is not just about making the process more efficient; it’s about creating a better, more sustainable, and consumer-centric product.

In the world of commercial air fryer production, several successful launches have reshaped the market and influenced consumer preferences. Let’s delve into some notable case studies that highlight the impact of innovative design and marketing strategies.

One such case study is the introduction of the SmartFry Pro Series by GourmetAir. This line of commercial air fryers was a game-changer due to its advanced features and sleek design. The Pro Series featured an integrated touch screen interface, allowing operators to control cooking temperatures and times with precision. This not only improved efficiency but also enhanced the quality of the food produced. The SmartFry Pro Series quickly gained popularity among restaurant owners and foodservice operators, leading to a significant increase in sales for GourmetAir.

Another example is the AirBake line from Elite Commercial Appliances. The AirBake series was designed with a focus on energy efficiency and ease of use. The compact and durable fryers were perfect for small to medium-sized restaurants, offering a cost-effective solution without compromising on performance. The innovative convection system allowed for a crispier exterior and a juicier interior, which was a hit with customers. The AirBake brand saw a surge in demand, with many establishments opting for their fryers over traditional deep fryers.

A unique case study comes from the EcoChef brand, which launched their EcoFry line with an emphasis on sustainability. The EcoFry air fryers were engineered to use up to 80% less oil than traditional fryers, significantly reducing the environmental impact and operational costs for businesses. The design also incorporated eco-friendly materials, further appealing to environmentally conscious consumers. This strategic approach to marketing and product development resulted in a strong market presence for EcoChef, with many businesses choosing their air fryers for their eco-friendly credentials.

The success of the TurboFry line from PowerChef can be attributed to its cutting-edge technology and versatility. The TurboFry series included fryers that could handle a wide range of cooking tasks, from frying to baking and even roasting. This multi-functional approach was highly appealing to operators looking to streamline their kitchen operations and reduce the number of appliances needed. The fryers also featured a self-cleaning function, which minimized downtime and maintenance requirements. The TurboFry line quickly became a top choice among commercial kitchens, driving sales and solidifying PowerChef’s position in the market.

A case study that stands out for its marketing innovation is the launch of the FusionFry by Fusion Appliances. This line of air fryers was designed to cater to a diverse customer base, offering both traditional and modern features. The FusionFry was available in various colors and finishes, allowing businesses to customize their fryers to match their brand identity. Additionally, Fusion Appliances partnered with renowned chefs to create exclusive recipes that could be cooked using their air fryers, thereby associating their brand with culinary expertise. This integrated marketing strategy was highly effective, as it not only sold the product but also created a community of loyal customers around the FusionFry brand.

In another instance, the launch of the RapidFry series by QuickCook Appliances was met with considerable success due to its emphasis on speed and efficiency. The RapidFry fryers were engineered to cook food up to 50% faster than conventional methods, making them ideal for busy restaurants and fast-food establishments. The compact design also made them space-saving, a crucial factor for many operators. The rapid cooking times and energy-saving capabilities of the RapidFry fryers attracted a wide range of customers, leading to a strong market adoption rate.

Finally, the introduction of the SmartCook line by KitchenTech has been a landmark in the commercial air fryer industry. This series integrated IoT technology, allowing operators to monitor and control their fryers remotely via a smartphone app. The SmartCook fryers also featured predictive maintenance alerts, reducing the risk of downtime and costly repairs. The innovative use of technology not only enhanced the user experience but also set KitchenTech apart from competitors. The SmartCook line has become a benchmark for smart kitchen appliances, driving growth and innovation in the commercial air fryer market.

These case studies illustrate the importance of innovation, design, and marketing in the commercial air fryer industry. By understanding consumer demands and leveraging technology, manufacturers have been able to create products that not only meet but exceed expectations, leading to successful market penetration and long-term customer loyalty.

In the ever-evolving commercial air fryer industry, challenges are as diverse as the products themselves. From manufacturing hurdles to market demands, navigating these obstacles requires innovative solutions and a strategic approach. Here’s an exploration of some of the key challenges faced and the creative ways they’re being addressed.

Material Sourcing and Quality ControlMaintaining high-quality standards in the production of commercial air fryers involves a meticulous process of sourcing materials. Finding suppliers who can consistently deliver premium components without compromising on price is a challenge. However, some factories have tackled this by establishing long-term partnerships with reliable suppliers, ensuring a steady supply of top-notch materials. Additionally, implementing rigorous quality control measures at each stage of production has helped to minimize defects and enhance the longevity of the appliances.

Regulatory ComplianceThe commercial kitchen appliance industry is heavily regulated, with different countries having their own standards and certifications. Adhering to these can be daunting, especially for companies looking to expand into new markets. To overcome this, many air fryer factories have invested in certification programs and are staffed with regulatory experts who stay updated on the latest requirements. By ensuring compliance, these factories can confidently enter new territories without legal hurdles.

Energy Efficiency and SustainabilityAs environmental concerns grow, the demand for energy-efficient appliances has surged. Designing air fryers that are both powerful and energy-saving is a significant challenge. Factories have responded by incorporating advanced technology such as smart heating elements and optimized fan systems. These innovations not only reduce energy consumption but also extend the life of the appliance, making them more attractive to eco-conscious consumers.

Innovation in Design and FunctionalityKeeping up with the latest trends in design and functionality is crucial for standing out in a crowded market. Air fryer factories are constantly seeking to innovate by integrating new features such as touchscreens, preset cooking modes, and even Bluetooth connectivity. These features not only enhance the user experience but also open up new marketing opportunities. By staying ahead of the curve, these factories can attract tech-savvy consumers who are looking for the latest in kitchen technology.

Market Saturation and Consumer PreferencesThe commercial air fryer market is becoming increasingly saturated, with a wide range of brands and models available. Differentiating a product from the competition is challenging. Factories are addressing this by focusing on niche markets and tailoring their products to specific consumer preferences. For instance, some are producing commercial air fryers with specific capacities or features to cater to high-volume restaurants or health-conscious diners. This targeted approach helps to carve out a unique position in the market.

Supply Chain DisruptionsGlobal supply chain disruptions have become a norm in recent years, impacting the production schedules of many factories. To mitigate the risk, some air fryer manufacturers have diversified their supply chains, sourcing components from multiple regions. This strategy not only reduces dependence on a single supplier but also provides a buffer against unexpected delays. Moreover, some factories have invested in inventory management systems to ensure they can quickly respond to changes in demand.

Customer Service and WarrantiesOffering exceptional customer service and reliable warranties is essential for building trust and loyalty. However, it can be challenging to maintain high service standards while managing a large customer base. Many air fryer factories have introduced comprehensive customer service programs, including 24⁄7 support and expedited repair services. By ensuring that their customers feel supported, these factories can foster a positive brand image and encourage repeat purchases.

Evolving Safety StandardsSafety is paramount in the kitchen appliance industry. With safety standards continually evolving, air fryer factories must stay informed about new regulations and incorporate them into their products. Regular safety audits and adherence to the latest safety protocols are critical. By doing so, factories not only protect their customers but also demonstrate their commitment to safety, which can be a significant selling point.

Competitive Pricing StrategiesPricing commercial air fryers competitively without compromising on quality is a delicate balance. Factories are addressing this challenge by optimizing production processes, reducing waste, and negotiating better deals with suppliers. Additionally, some are exploring subscription-based models or offering bundle deals to attract cost-conscious buyers while still making a profit.

Global Expansion and LocalizationExpanding into international markets requires adapting products to local preferences and regulations. This can be a complex task, but it’s essential for growth. Factories are employing localization strategies by working with local experts to understand market dynamics and tailoring their offerings accordingly. By doing so, they can effectively navigate cultural differences and successfully penetrate new markets.

In the ever-evolving landscape of the commercial air fryer industry, several key challenges and innovative solutions have emerged to keep the market dynamic and competitive. From adapting to changing consumer preferences to navigating regulatory hurdles, here’s a closer look at the industry’s challenges and the strategies being employed to overcome them.

The demand for healthier cooking options has surged, pushing manufacturers to develop air fryers that not only offer health benefits but also cater to the convenience and taste expectations of consumers. This shift has necessitated a focus on energy efficiency and the use of high-quality, non-toxic materials. Solutions include the integration of smart technology that allows for precise temperature control and the incorporation of air circulation systems that reduce the need for excessive oil.

Regulatory compliance is a significant challenge, especially as new health and safety standards are introduced. To tackle this, factories are investing in certifications and quality control processes. They’re also staying abreast of international regulations to ensure that their products meet the requirements of various markets, from the European Union to the United States and beyond.

One of the most prominent challenges is the rapid pace of technological advancements. Keeping up with the latest innovations requires continuous investment in research and development. Factories are responding by fostering a culture of innovation, encouraging their engineers to explore new materials and manufacturing techniques. This has led to the development of air fryers with features like programmable settings, Bluetooth connectivity, and even AI-driven cooking recommendations.

The complexity of supply chains has also presented a challenge. Global supply disruptions, particularly during the COVID-19 pandemic, have highlighted the importance of diversifying suppliers and reducing dependency on a single source. Many factories have adapted by establishing partnerships with multiple suppliers and investing in local production capabilities to mitigate the risks associated with international logistics.

In the realm of sustainability, the industry faces the challenge of reducing its environmental footprint. Solutions include the use of recycled materials, energy-efficient production processes, and the development of air fryers that are designed for longevity and easy repair. Some companies are even exploring the use of biodegradable packaging and the creation of products that can be easily recycled at the end of their life cycle.

Another challenge is the need to differentiate products in a crowded market. Factories are addressing this by focusing on unique selling points (USPs), such as innovative cooking technology, exclusive recipes, and distinctive designs. By offering something unique, they can capture the attention of consumers and build brand loyalty.

The cost of raw materials has also been a concern, particularly for components like plastic and metal. To combat this, factories are seeking alternatives and exploring the use of composite materials that offer cost savings without compromising quality. They’re also looking into just-in-time manufacturing and efficient inventory management to minimize waste and reduce costs.

Consumer safety is paramount, and the industry must constantly monitor and improve product safety standards. This involves rigorous testing and the implementation of safety features such as overheat protection and auto shut-off mechanisms. Factories are investing in advanced testing equipment and safety protocols to ensure that their products meet the highest safety standards.

The challenge of market saturation is real, and factories are finding creative ways to stand out. This includes targeted marketing campaigns that speak to specific demographics, strategic partnerships with restaurants and food service providers, and the development of custom solutions for niche markets.

In summary, the commercial air fryer industry faces a multitude of challenges, from health and safety regulations to supply chain complexities and environmental concerns. However, through innovation, strategic partnerships, and a commitment to excellence, factories are finding solutions that not only meet the demands of today’s consumers but also position them for success in the future.

In the ever-evolving world of kitchen appliances, the commercial air fryer has emerged as a beacon of innovation and efficiency. As we draw to the close of this exploration, it’s clear that the rise of commercial air fryers is not just a trend—it’s a transformative shift in the culinary landscape. Here’s a closer look at what this surge signifies and why it’s poised to redefine the future of food preparation.

The commercial air fryer’s popularity is a testament to its versatility and health benefits. By offering a healthier alternative to traditional frying methods, these appliances have become a favorite among health-conscious consumers. The ability to cook a variety of foods with minimal oil has not only reduced the calorie count but also the guilt associated with indulgent treats.

As the demand for healthier eating options continues to grow, so does the market for commercial air fryers. The convenience of these machines, which can quickly cook a variety of foods, from crispy French fries to succulent chicken wings, has made them a staple in busy kitchens and restaurants alike. Their compact size and energy efficiency have also made them a favorite among eco-conscious consumers.

The rise of commercial air fryers is not just a reflection of changing consumer preferences; it’s also a nod to technological advancements. The integration of smart features, such as programmable settings and temperature control, has elevated the air fryer from a simple kitchen gadget to a sophisticated appliance. These features not only enhance the cooking experience but also provide users with the confidence to experiment with different recipes.

In recent years, we’ve seen a surge in the number of brands entering the commercial air fryer market. Each brings its unique design and functionality, creating a diverse range of options for consumers. From countertop models to integrated units, the variety is impressive. This competition has driven innovation, with manufacturers constantly seeking to outdo each other in terms of performance, design, and user experience.

Despite the many benefits, the commercial air fryer industry faces its fair share of challenges. One of the most significant is the need for education and awareness about the product. Many consumers are still unfamiliar with air frying and its health benefits, which can limit the market’s potential. Brands are addressing this by investing in marketing campaigns that highlight the advantages of air frying and how it can fit into a balanced diet.

Another challenge is the sustainability of the materials used in air fryer production. As consumers become more environmentally conscious, the demand for eco-friendly appliances is on the rise. Manufacturers are responding by exploring sustainable materials and manufacturing processes that reduce waste and minimize the carbon footprint.

Looking ahead, the future of commercial air fryers is bright. One of the most exciting opportunities lies in the customization and personalization of these appliances. Imagine a world where your air fryer not only cooks your food but also learns your preferences over time. Smart technology could enable air fryers to tailor cooking times and temperatures to your taste, making each meal a unique culinary experience.

The integration of air fryers into smart home ecosystems is another area ripe for growth. As more homes adopt voice assistants and smart kitchen devices, air fryers could become part of a seamless cooking experience. Users could program their appliances through voice commands, receive notifications about cooking progress, and even have their favorite recipes automatically downloaded.

The rise of commercial air fryers has also sparked a renewed interest in healthier cooking methods. This shift has led to the development of new ingredients and cooking techniques that complement the air frying process. We can expect to see a surge in innovative food products designed specifically for air frying, further expanding the market’s appeal.

In conclusion, the rise of commercial air fryers is a story of innovation, consumer demand, and technological advancement. It’s a narrative that shows how a simple kitchen gadget can become a catalyst for change. As we move forward, the commercial air fryer market is poised to continue its upward trajectory, driven by the relentless pursuit of healthier, more efficient, and personalized cooking experiences.