Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, the dual voltage sandwich press has emerged as a versatile and convenient option for home chefs and food enthusiasts alike. This innovative appliance offers a unique blend of functionality and ease, catering to a global market that craves consistency in cooking results. As we delve into the intricacies of the dual voltage sandwich press, we’ll uncover the market trends shaping its popularity, explore the creative ideas fueling its product development, and highlight the pivotal role of OEMs in driving innovation. Additionally, we’ll examine the distinct advantages these presses bring to the table, delve into case studies of successful product launches, navigate the regulatory challenges they face, and finally, gain insights into consumer preferences and the future outlook for dual voltage sandwich presses.

The dual voltage sandwich press market has emerged as a significant segment within the kitchen appliances industry, offering a versatile solution for home chefs and commercial kitchens alike. With the ability to operate efficiently across different voltage systems, these presses have gained popularity for their convenience and functionality. This article delves into the intricacies of the dual voltage sandwich press market, exploring its growth, consumer demand, and the innovative products that are shaping the landscape.

The concept of a sandwich press is not new, but the dual voltage capability has revolutionized its appeal. These presses are designed to work seamlessly in regions where the standard voltage differs, such as the United States (120V) and Europe (240V), making them a sought-after item for global travelers and expatriates. The market for these versatile appliances has been witnessing a steady rise, driven by the growing interest in home cooking and the demand for high-quality, multi-functional kitchen tools.

One of the key factors contributing to the market’s growth is the increasing awareness of health and wellness. As more people opt for homemade meals over processed foods, the convenience of a sandwich press becomes apparent. It allows users to prepare a variety of sandwiches, paninis, and melts quickly and easily, without the need for additional cooking appliances.

Consumers are also drawn to the convenience factor of dual voltage sandwich presses. These devices eliminate the need for voltage converters or transformers, simplifying the travel experience for those who frequently move between countries with different electrical standards. The ease of use and portability of these presses make them an attractive option for both personal and professional settings.

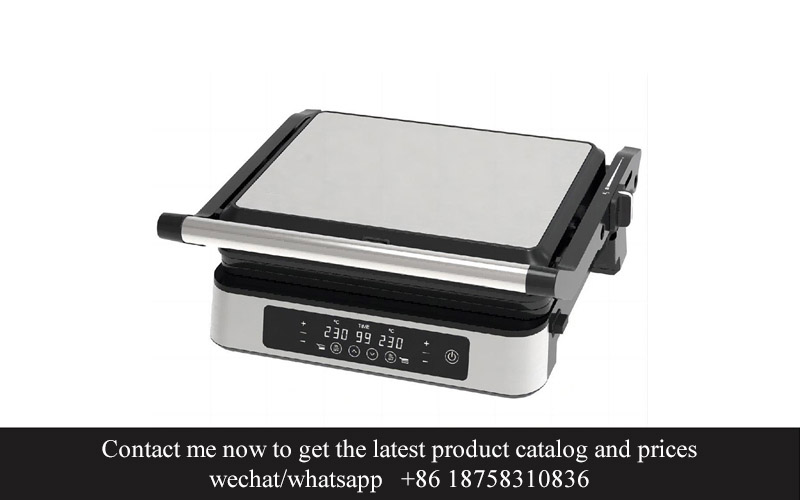

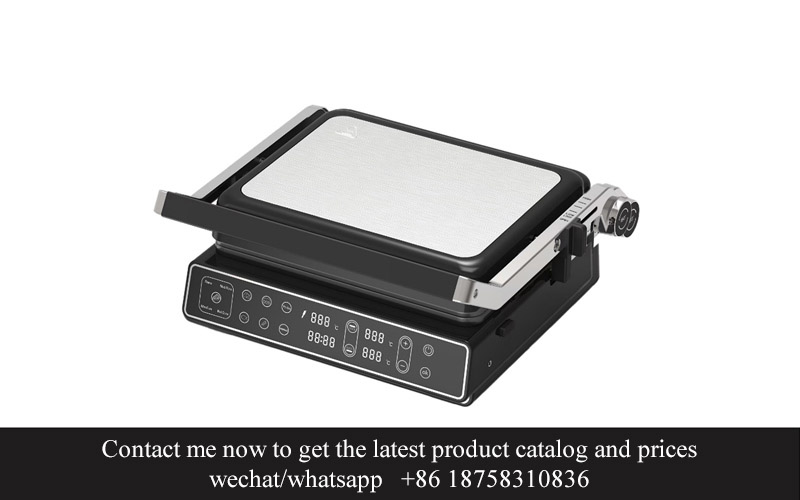

In terms of product development, the sandwich press market is witnessing a surge in innovation. Manufacturers are continuously pushing the boundaries of design and functionality, offering features such as non-stick surfaces, adjustable heating elements, and even built-in timers. These advancements not only enhance the cooking experience but also cater to the diverse preferences of consumers who seek both convenience and quality.

The market for dual voltage sandwich presses is not limited to residential use. Many cafes, delis, and food trucks have also embraced these appliances due to their efficiency and ability to provide a consistent product. The commercial-grade sandwich presses are often equipped with heavy-duty components and are built to withstand frequent use, making them a practical choice for businesses that prioritize speed and reliability.

Another important aspect of the dual voltage sandwich press market is the rise of online sales. With the advent of e-commerce, customers can now easily purchase these appliances from the comfort of their homes. Online retailers have expanded their product offerings, providing a wider variety of dual voltage sandwich presses at competitive prices. This has further fueled the market’s growth, as more consumers discover the benefits of these versatile appliances.

Despite the market’s growth, challenges remain. One of the primary concerns is the regulatory compliance for dual voltage appliances. Different countries have varying standards for electrical safety, and manufacturers must ensure that their products meet these requirements. This can be a complex and time-consuming process, requiring extensive testing and certification.

Additionally, consumer education about the benefits of dual voltage sandwich presses is crucial. Many potential buyers may not be aware of the convenience and cost-effectiveness of these appliances, especially when traveling internationally. As awareness grows, however, it is expected that the market will continue to expand.

In conclusion, the dual voltage sandwich press market is a dynamic and evolving sector within the kitchen appliances industry. With its ability to cater to diverse consumer needs and preferences, the market is poised for further growth. As manufacturers continue to innovate and adapt to the changing landscape, dual voltage sandwich presses are likely to become an even more integral part of modern kitchens around the world.

The 120V/240V dual voltage feature in sandwich presses is a game-changer for both consumers and manufacturers. This unique capability allows these appliances to operate seamlessly across different electrical standards, making them highly versatile and appealing in various regions around the world. Let’s delve into the intricacies of this dual voltage feature and its impact on the sandwich press market.

Global Electrical Standards: Understanding the 120V/240V dual voltage feature requires a grasp of the global electrical standards. In the United States and Canada, electrical outlets typically operate at 120V, while most European countries use a standard of 240V. This dual voltage capability ensures that a single sandwich press can cater to both markets without requiring modifications.

Flexibility for Travelers: For those who travel frequently, the dual voltage feature is invaluable. It means that a sandwich press purchased in the United States can be used in Europe, Asia, and other parts of the world without the need for a voltage converter or adapter. This convenience is particularly appealing to expatriates, tourists, and globetrotters.

Market Expansion for Manufacturers: By offering a dual voltage sandwich press, manufacturers can tap into a wider customer base. They no longer need to produce separate models for different regions, which reduces production costs and inventory management challenges. This streamlined approach also allows for quicker market response to consumer demands.

Power Efficiency Considerations: While dual voltage capability is a significant advantage, it’s essential to consider power efficiency. Appliances designed for 240V often consume less power than those designed for 120V to deliver the same performance. This efficiency can lead to cost savings over time, especially in regions with higher electricity rates.

Innovative Design for Safety: Sandwich presses with dual voltage features often incorporate innovative safety designs. These may include built-in surge protectors, automatic shut-off mechanisms, and safety interlocks to prevent accidents. These features are crucial for ensuring that the appliance is safe to use in any electrical environment.

Customization and Branding: For OEMs (Original Equipment Manufacturers) and private label brands, the dual voltage feature offers an opportunity to customize products to meet specific market needs. Brands can tailor their sandwich presses with regional preferences in mind, such as power buttons labeled in multiple languages or specific power outlets compatible with various standards.

Technological Integration: With the rise of smart kitchen appliances, the dual voltage feature is increasingly being paired with smart technology. Users can now control their sandwich presses remotely via smartphones or tablets, adjusting settings and monitoring cooking times from anywhere. This integration enhances the user experience and adds value to the product.

Testing and Compliance: Ensuring that a sandwich press operates safely and effectively at both 120V and 240V requires rigorous testing. Manufacturers must adhere to international safety standards and certifications, which can be a complex and time-consuming process. However, it is a necessity to maintain trust and compliance in the market.

Consumer Education: With the introduction of dual voltage sandwich presses, there is a need for consumer education. Users must understand how to safely switch between voltage settings and be aware of the potential risks associated with incorrect usage. Providing clear instructions and user manuals is crucial for consumer safety and satisfaction.

Sustainability and Environmental Impact: The dual voltage feature contributes to sustainability by reducing the need for multiple products for different regions. This not only minimizes waste but also reduces the environmental impact of shipping and manufacturing additional models. As consumers become more environmentally conscious, this aspect can be a significant selling point for manufacturers.

Competitive Advantage: Offering a dual voltage sandwich press can provide a competitive edge in the market. It demonstrates a commitment to innovation and customer satisfaction, which can attract both new customers and brand loyalists. This feature can also be used as a unique selling proposition in marketing campaigns.

Long-Term Cost Savings: For consumers, the initial investment in a dual voltage sandwich press may be higher than that of a single-voltage model. However, over time, the cost savings from not needing additional appliances for different regions can offset this initial expense. This long-term financial benefit is an important consideration for many buyers.

In summary, the 120V/240V dual voltage feature in sandwich presses is a multifaceted innovation that enhances the user experience, streamlines manufacturing processes, and expands market opportunities. It is a testament to the evolving landscape of kitchen appliances and the importance of adaptability in a global marketplace.

The sandwich press industry has witnessed a surge in innovation and consumer demand over the years. Several key trends have shaped the landscape, reflecting the evolving preferences and technological advancements in the market.

Health and Wellness Focus: There’s a growing emphasis on healthy eating habits, and this trend has seeped into the sandwich press market. Consumers are seeking appliances that can help them prepare nutritious, homemade sandwiches without the added preservatives found in store-bought options.

Smart Technology Integration: The incorporation of smart technology in sandwich presses has become increasingly popular. Features like programmable settings, digital displays, and even Bluetooth connectivity for remote control have made these appliances more user-friendly and versatile.

Design and Aesthetics: The design of sandwich presses has evolved from utilitarian to stylish and decorative. Modern models often feature sleek designs, non-slip bases, and materials that are easy to clean, catering to the aesthetic sensibilities of today’s consumers.

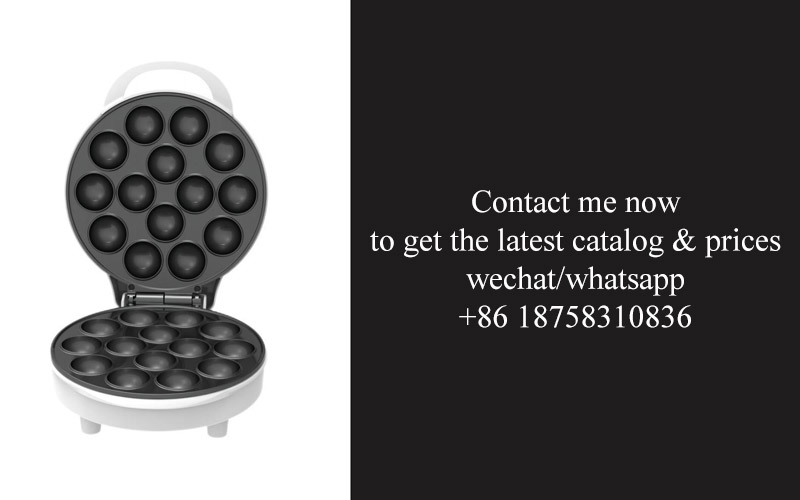

Versatility in Functionality: While traditional sandwich presses are still popular, the market has expanded to include models that can cook a variety of foods beyond sandwiches. Grilled cheese, paninis, wraps, and even omelets can now be prepared with the help of these versatile appliances.

Miniaturization and Portability: There’s a noticeable trend towards smaller, more portable sandwich presses. These compact models are perfect for camping, picnics, or for those with limited kitchen space. They offer the convenience of enjoying a freshly cooked meal anywhere.

Sustainability and Eco-Friendly Options: As environmental concerns grow, so does the demand for eco-friendly appliances. Sandwich presses made from sustainable materials, with energy-efficient designs, are becoming more attractive to environmentally conscious consumers.

Customization and Personalization: Consumers are looking for more control over their cooking experience. Sandwich presses with adjustable heat settings, browning levels, and various press plate shapes allow for personalized cooking and the creation of unique sandwich variations.

Health and Safety Features: Safety has always been a priority, but recent models have introduced additional features to enhance user safety. This includes non-stick surfaces that reduce the risk of burns, automatic shut-off mechanisms to prevent overheating, and cool-touch handles.

Global Market Expansion: The popularity of sandwich presses is not limited to any one region. As people become more accustomed to the convenience of these appliances, the market is expanding globally, with different variations catering to local tastes and preferences.

Influencer and Social Media Influence: Influencers and social media platforms play a significant role in shaping market trends. The rise of content creators showcasing their culinary skills using sandwich presses has led to increased consumer interest and sales.

Innovation in Materials: There’s a constant push for innovation in materials used in sandwich presses. From high-quality stainless steel to advanced non-stick coatings, the industry is always seeking to improve durability and performance.

E-commerce Growth: The rise of online shopping has had a profound impact on the sandwich press industry. More brands are selling their products directly to consumers through e-commerce platforms, which has expanded their reach and increased market competition.

The sandwich press industry is dynamic, with trends constantly evolving. Brands that stay attuned to these changes and adapt their products accordingly will likely find success in a market that is ripe for innovation and growth.

In the ever-evolving landscape of kitchen appliances, the sandwich press has seen a surge in innovation. Here are some creative ideas that are shaping the future of sandwich press products:

Smart Technology Integration: Modern sandwich presses are not just for cooking; they’re becoming smart kitchen companions. Imagine a sandwich press that can connect to your smartphone, allowing you to remotely monitor the cooking process and adjust settings for different types of bread and fillings.

Variable Temperature Control: While most sandwich presses operate at a single temperature, what if you could choose from a range of heat settings? This would allow for a variety of sandwich styles, from crispy to soft, catering to individual preferences.

Eco-Friendly Materials: As sustainability becomes a key concern, sandwich presses made from recycled materials or biodegradable plastics are gaining traction. These eco-conscious options appeal to environmentally aware consumers.

Design Customization: Why stick to a standard shape when you can have a sandwich press that matches your kitchen decor? Customizable designs, perhaps with interchangeable panels or unique patterns, could become a hit with design-savvy consumers.

Health and Wellness Features: With the rise of health-conscious eating, sandwich presses could incorporate features that promote wellness. For instance, a press with a non-stick surface that’s also free from harmful chemicals, or a model that can cook sandwiches with minimal oil.

Multi-Functional Presses: Why limit a sandwich press to just sandwiches? What if it could also toast bread, cook paninis, or even grill vegetables? A multi-functional press that can handle a variety of tasks could save space and time in the kitchen.

Personalized Recipes and Cooking Times: Imagine a sandwich press that comes with a built-in recipe book or an app that suggests recipes based on your ingredients. It could even have pre-set cooking times for different recipes, ensuring perfect results every time.

Safety and Convenience Features: Safety is always a priority, and sandwich presses could incorporate features like cool-touch handles, child locks, and automatic shut-off to prevent burns and accidents. Additionally, a sleeker design that’s easier to clean would be a welcomed addition.

Interactive Learning Mode: For those who are new to cooking or want to learn new techniques, a sandwich press with an interactive learning mode could be a game-changer. It could guide users through the process with step-by-step instructions and visual cues.

Augmented Reality (AR) Enhancements: An AR feature could allow users to see how their sandwich will look before they cook it, or even simulate different cooking outcomes. This could be a fun and engaging way to experiment with different sandwich combinations.

Energy Efficiency: With energy costs on the rise, a sandwich press that’s highly energy-efficient could be a major selling point. This could include features like an auto-sleep mode that turns off the press when not in use.

Customizable Press Patterns: For those who love a good crunch, a sandwich press with customizable press patterns could be a hit. Users could choose from various textures, from a gentle press to a firm, satisfying crunch.

Interactive Feedback System: A press that provides real-time feedback on the cooking process, such as a visual or auditory signal when the sandwich is perfectly toasted, could add a fun element to the cooking experience.

Subscription-Based Content: Similar to smart kitchen gadgets, a sandwich press could offer a subscription service that provides new recipes, cooking tips, and even discounts on accessories like sandwich fillings.

Sustainability Initiatives: Finally, companies could partner with local bakeries or farms to offer sandwiches that are not only delicious but also support local businesses and reduce food miles.

These innovative ideas aim to enhance the sandwich press experience, making it more personalized, efficient, and enjoyable for consumers. As the industry continues to evolve, the possibilities for creative sandwich press products are virtually limitless.

In the sandwich press industry, Original Equipment Manufacturers (OEMs) play a pivotal role in shaping the market and driving innovation. They are the architects behind the scenes, crafting the products that capture consumer interest and meet the evolving demands of the market. Here’s a closer look at the multifaceted role of OEMs in this sector:

OEMs are the bridge between the design and production phases, ensuring that the vision of a product concept is realized with precision and efficiency. They source the best materials, often from global suppliers, to create durable and reliable sandwich presses. This careful selection process is crucial, as the quality of the components directly impacts the end product’s performance and lifespan.

Customization is a key strength of OEMs in the sandwich press sector. They understand that not all kitchens are the same, and thus, they offer tailored solutions to meet specific requirements. From compact models for small spaces to commercial-grade presses for high-volume use, OEMs can adapt their designs to fit a wide range of customer needs. This flexibility allows them to cater to both retail and commercial markets.

Innovation is at the heart of the OEMs’ strategy. They invest in research and development to introduce new features and functionalities that set their products apart. For instance, some OEMs are integrating smart technology into sandwich presses, allowing users to control the cooking process remotely or to receive notifications when the perfect sandwich is ready. These advancements not only enhance the user experience but also open up new possibilities for product lines.

The manufacturing process is another area where OEMs excel. They manage production lines with a focus on efficiency and quality control. By optimizing their production processes, OEMs can reduce costs while maintaining high standards. This efficiency is particularly important in a competitive market where cost-effectiveness is a significant selling point.

OEMs also play a crucial role in regulatory compliance. They ensure that their products meet all local and international safety standards, which is essential for both the consumer and the reputation of the brand. This includes certifications for electrical safety, fire resistance, and material health and safety.

The relationship between OEMs and their clients is collaborative and strategic. They often work closely with distributors and retailers to understand market trends and consumer preferences. This partnership helps OEMs stay ahead of the curve by anticipating shifts in demand and adapting their product lines accordingly.

Another vital aspect of OEMs’ role is in the realm of after-sales service. They provide technical support and maintenance services to ensure that customers have a positive experience with their sandwich presses. This support is not only about fixing issues but also about providing tips and tricks to maximize the appliance’s potential.

In the context of sustainability, OEMs are increasingly focusing on eco-friendly practices. They are exploring alternative materials and energy-efficient designs to reduce the environmental impact of their products. This commitment to sustainability is not just a trend but a long-term strategy that resonates with environmentally conscious consumers.

Lastly, OEMs are instrumental in global expansion. As the sandwich press market continues to grow, they help brands enter new markets by adapting products to local tastes and regulations. This international reach allows OEMs to leverage their expertise to create a global footprint for their clients.

In summary, OEMs in the sandwich press sector are the unsung heroes behind the appliances that grace our kitchen counters. They are the architects of innovation, the custodians of quality, and the strategists of market expansion. Their role is multifaceted, encompassing design, production, compliance, and customer satisfaction, all of which are essential for the success of any sandwich press brand.

In today’s fast-paced culinary world, the demand for efficient and versatile kitchen appliances is on the rise. One such innovation that has gained traction is the 120V/240V dual voltage sandwich press. This versatile kitchen gadget offers a range of benefits that cater to diverse users and environments. Let’s delve into the advantages that make these sandwich presses a standout choice for both home chefs and commercial kitchens.

The adaptability of dual voltage technology is a game-changer for sandwich presses. Users can effortlessly switch between 120V and 240V power sources, making these devices suitable for use across the globe. Whether you’re a traveler, a military personnel, or simply moving to a different country, the dual voltage feature ensures that your sandwich press remains operational without the need for complex power converters or transformers.

Another significant benefit is the even heat distribution. Traditional sandwich presses might struggle to maintain a consistent temperature, often leading to undercooked or overcooked sandwiches. However, the dual voltage technology in these presses allows for precise temperature control, ensuring that every sandwich is cooked to perfection. This feature is especially crucial for commercial establishments that serve a high volume of customers, as it reduces waste and improves customer satisfaction.

The versatility of 120V/240V dual voltage sandwich presses extends to their design and functionality. Many models come with non-stick surfaces, which not only make cleanup a breeze but also prevent food from sticking to the press. This is particularly advantageous in busy kitchens where quick and easy cleanup is essential.

For health-conscious consumers, the ability to control the cooking temperature is a major benefit. The dual voltage sandwich presses often come with adjustable heat settings, allowing users to customize the cooking intensity according to their preference. This means you can achieve a perfectly toasted outer layer while keeping the sandwich’s innards soft and warm.

One of the standout advantages of these sandwich presses is their portability. They are typically lightweight and compact, making them ideal for camping trips, RVs, or small apartments where space is at a premium. Their small footprint doesn’t compromise on performance, offering high-quality results in a travel-friendly package.

In the commercial setting, the dual voltage capability of these sandwich presses is a strategic advantage. They can be used in various locations without worrying about compatibility with the local power grid. This flexibility is crucial for food trucks, outdoor events, and pop-up shops that may move from one venue to another.

Moreover, the dual voltage feature is also a cost-saving benefit. By being able to use the press in different countries, users can avoid the expense of purchasing multiple appliances for different power outlets. This is particularly relevant for international companies that have branches or franchises worldwide.

Safety is another critical aspect where the dual voltage sandwich presses excel. They are designed with built-in safety features like automatic shut-offs and overheating protection, ensuring that the device operates safely even under extended use. This is especially important in commercial kitchens where appliances are often used for extended periods.

For home chefs, the dual voltage sandwich press can be a versatile tool for experimenting with various sandwich recipes. The ability to adjust the cooking temperature and control the browning of the bread adds a level of customization that traditional sandwich makers lack.

The environmental impact of kitchen appliances is also a growing concern. Dual voltage sandwich presses are eco-friendly as they reduce the need for additional electrical devices and can be used efficiently across different power sources, contributing to lower energy consumption.

In conclusion, the benefits of 120V/240V dual voltage sandwich presses are multifaceted. From adaptability and even heating to portability and safety, these devices offer a comprehensive solution for individuals and businesses looking to enhance their culinary experiences. As the demand for versatile and efficient kitchen appliances continues to rise, the dual voltage sandwich press stands out as a smart and practical choice.

In the world of kitchen appliances, the dual voltage sandwich press has emerged as a game-changer, offering versatility and convenience to consumers across different regions. Let’s delve into some notable case studies that showcase the successful launches of these innovative sandwich presses.

The launch of the “Global Gourmet” dual voltage sandwich press was met with excitement in the European market. This model, designed to operate seamlessly on both 120V and 240V power systems, was a hit among expatriates and international travelers who craved a taste of home while living abroad. The press’s ability to lock into the local voltage without the need for transformers or voltage converters was a significant draw for its target demographic.

Another standout case study is the “Urban Baker” sandwich press, which was introduced in the bustling city of Tokyo, Japan. The sleek design and compact size of this press made it an instant favorite among busy professionals looking for a quick and easy way to prepare gourmet sandwiches for their lunch breaks. The dual voltage feature allowed the press to be used in Japanese homes without any compatibility issues, further solidifying its popularity.

In the United States, the “American Delight” dual voltage sandwich press took the market by storm. Its ability to cook sandwiches in less than two minutes and its adjustable heat settings were praised by both home chefs and casual users alike. The press’s success can be attributed to its intuitive controls and the fact that it could be used in various settings, from a countertop in a small apartment to a kitchen in a large household.

The “Culinary Craft” dual voltage sandwich press, launched in Australia, catered to the health-conscious consumer who sought a way to enjoy homemade sandwiches without the added preservatives and fillings found in store-bought varieties. The press’s non-stick surface and ability to cook sandwiches with minimal oil were perfect for those looking to maintain a balanced diet. The dual voltage capability ensured that the press could be used in Australian homes without any hassle.

The “Bistro Pro” dual voltage sandwich press, which made its debut in the UK, was a hit among small café owners and food trucks. Its sturdy build and professional-grade features allowed for consistent and high-quality sandwich preparation, which was essential for these businesses. The press’s dual voltage feature was particularly beneficial for the UK’s diverse power supply, ensuring compatibility with various outlets without the need for additional adaptors.

In the Middle East, the “Arabian Bites” dual voltage sandwich press was a hit with families and individuals who enjoyed making their own versions of traditional sandwiches. The press’s ability to cook a variety of fillings, from meat to vegetables, and its easy-to-clean design were highly appreciated. The dual voltage aspect allowed the press to be used in homes with both 120V and 240V systems, making it a versatile choice for the region.

In each of these case studies, the dual voltage sandwich press has proven to be a versatile and practical kitchen appliance. Its ability to operate on different voltage systems has opened up new markets and appealed to a wide range of consumers. From busy professionals to families, these presses have become a staple in many kitchens around the world, offering convenience, health benefits, and the joy of homemade sandwiches.

Understanding the complexities of dual voltage appliances, such as the 120V/240V sandwich presses, requires a keen awareness of the regulatory landscape that governs their design, manufacturing, and distribution. Here’s a closer look at the intricacies involved:

The Importance of ComplianceEnsuring that dual voltage appliances meet the necessary safety standards is paramount. These standards vary by region and are set by organizations like the Underwriters Laboratories (UL) in the United States, the Conformité Européenne (CE) in Europe, and others globally. Compliance not only guarantees safety but also opens up markets for manufacturers and distributors.

Regional Variations in RegulationsDifferent regions have different voltage systems, which means that appliances must be designed to operate effectively across these systems. For instance, the United States operates on a 120V system, while much of Europe uses a 230V system. Adapting to these variations requires careful engineering and testing to ensure that the appliance can safely switch between voltages without compromising performance or safety.

Safety Standards and CertificationsSafety standards for dual voltage appliances are rigorous and encompass a range of tests. These include electrical safety, material flammability, and user interface safety. Appliances must pass these tests to receive certifications like UL, CE, or others, which are often required for market entry. The certification process can be lengthy and costly, but it’s essential for maintaining consumer trust and legal compliance.

Labeling and Marking RequirementsRegulatory landscapes also dictate specific labeling and marking requirements for dual voltage appliances. This includes information on voltage ratings, safety warnings, and compliance symbols. Proper labeling not only informs users but also serves as a visual indicator of the appliance’s adherence to safety standards.

Customization for Different MarketsManufacturers of dual voltage appliances often need to customize their products for specific markets. This can involve adapting the design to fit local power outlets, ensuring compatibility with local electrical systems, and even considering the cultural preferences of consumers. For example, a sandwich press designed for the European market might have different features or aesthetics compared to one intended for the United States.

Testing and Quality AssuranceRegular testing and quality assurance are crucial for maintaining compliance with regulatory standards. This includes not only initial product testing but also ongoing monitoring to ensure that appliances continue to meet safety requirements throughout their lifecycle. Quality control measures help prevent issues that could lead to product recalls or safety hazards.

The Impact of GlobalizationGlobalization has made it easier for manufacturers to distribute dual voltage appliances worldwide. However, it has also increased the complexity of navigating the regulatory landscape. Appliances must be designed to comply with various standards, which can be challenging given the differences in testing procedures and certification requirements across regions.

Collaboration with Local ExpertsTo navigate the regulatory landscape effectively, manufacturers often collaborate with local experts who have a deep understanding of the specific regulations in each market. These experts can provide valuable insights into the nuances of local requirements and help ensure that products are compliant without unnecessary delays.

The Role of TechnologyAdvancements in technology have made it easier to design and manufacture dual voltage appliances that can switch between voltages seamlessly. Smart technology and adaptive power systems allow appliances to detect and adjust to the voltage of the power source, reducing the need for manual intervention and ensuring consistent performance.

In conclusion, navigating the regulatory landscape for dual voltage appliances is a multifaceted challenge that requires a combination of technical expertise, compliance knowledge, and a commitment to safety. By understanding and adhering to these regulations, manufacturers can ensure that their products are not only safe but also marketable in a global environment.

In the realm of consumer electronics, understanding the nuances of consumer insights and preferences is paramount. From the kitchen to the office, the way people interact with technology can significantly influence the design and success of products. Here’s a delve into the world of consumer insights and preferences, particularly focusing on dual voltage appliances.

Modern consumers are more environmentally conscious than ever before, and this extends to the appliances they choose to bring into their homes. A preference for energy-efficient models is on the rise, and dual voltage sandwich presses are no exception. These devices not only cater to the need for efficiency but also align with the broader trend of sustainability.

The ease of use is another critical factor influencing consumer preferences. Appliances that are intuitive, require minimal setup, and provide clear instructions are more likely to be favored. In the case of dual voltage sandwich presses, users appreciate the convenience of being able to switch between voltage settings without the need for additional converters or adapters.

Customization is key in today’s market. Consumers are looking for products that can be tailored to their specific needs and preferences. For dual voltage sandwich presses, this could mean adjustable heat settings, non-stick surfaces that are easy to clean, or even features like built-in timers and temperature controls. The ability to customize the cooking experience can make a significant difference in customer satisfaction.

Safety is a top priority for many consumers. Features that enhance the safety of the appliance, such as cool-touch handles, automatic shut-off functions, and childproof locks, are highly valued. In the context of dual voltage sandwich presses, safety also involves ensuring that the appliance operates reliably across different voltage systems, reducing the risk of malfunction or electrical hazards.

Brand reputation plays a significant role in consumer decisions. Consumers often look to established brands that have a track record of producing reliable and high-quality products. When it comes to dual voltage sandwich presses, a reputable brand can provide peace of mind, knowing that the appliance has undergone rigorous testing and meets safety standards.

The rise of health-consciousness has also influenced consumer preferences. Many people are turning to homemade meals that are not only healthier but also more satisfying. Dual voltage sandwich presses offer a quick and easy way to prepare a variety of nutritious meals, from classic sandwiches to wraps and paninis. The ability to control the cooking temperature can help preserve the nutritional value of ingredients.

Technology integration is another trend that’s shaping consumer preferences. Smart appliances that can be controlled remotely via a smartphone app or connected to other smart home devices are becoming increasingly popular. For dual voltage sandwich presses, this could mean users can preheat the appliance or monitor the cooking process from their phone, adding a layer of convenience and control.

In terms of design, consumers are drawn to sleek, modern aesthetics that complement their kitchen decor. A dual voltage sandwich press that offers both functionality and a stylish design can be a strong selling point. The look of the appliance is not just about aesthetics; it can also reflect the brand’s values and the consumer’s desire for a cohesive kitchen environment.

Finally, the availability of customer support and warranty services can greatly impact consumer decisions. Knowing that they have access to help if something goes wrong or if they have questions about the appliance can provide consumers with the confidence to make a purchase.

Understanding these insights and preferences is crucial for manufacturers and retailers in the dual voltage sandwich press market. By aligning product development with these trends, companies can better meet the needs and expectations of their customers, leading to increased satisfaction and loyalty.

The dual voltage sandwich press market is on the rise, offering a versatile solution for home cooks and commercial kitchens alike. These appliances are designed to cater to a global audience, ensuring compatibility across different electrical standards. As we delve into the future of these innovative devices, it’s clear that their evolution will be shaped by several key factors. From technological advancements to changing consumer demands, the landscape is poised for exciting developments. Here’s a glimpse into what the future might hold for dual voltage sandwich presses.

The integration of smart technology is a trend that’s likely to gain traction in the dual voltage sandwich press sector. Imagine a press that not only cooks your sandwiches to perfection but also learns your preferences over time. With features like Wi-Fi connectivity, these appliances could be controlled remotely, allowing users to start their meal prep even before they arrive home. The potential for customization and convenience is vast, and manufacturers are already exploring how to incorporate these technologies seamlessly into their designs.

Energy efficiency is another area where dual voltage sandwich presses are poised to make a significant impact. As environmental concerns grow, consumers are increasingly looking for appliances that consume less energy. Innovations in heating elements and insulation could lead to more energy-efficient models that not only save on electricity bills but also reduce the carbon footprint. This shift towards sustainability is not just a trend but a necessity for the industry’s long-term viability.

The rise of health consciousness is prompting appliance manufacturers to focus on healthier cooking options. Dual voltage sandwich presses could offer solutions that minimize the use of oil and fat, making them a healthier choice for those watching their diet. Features like adjustable heat settings and non-stick surfaces could make it easier for users to create lighter, more nutritious sandwiches. This focus on health is not just about marketing; it’s about providing real value to consumers who are more mindful of their well-being.

Customization is key in the appliance market, and dual voltage sandwich presses are no exception. Imagine a press that allows users to choose from a variety of cooking patterns, from classic sandwiches to gourmet sliders. With modular components and interchangeable plates, these appliances could adapt to a wide range of culinary styles. The ability to cater to diverse tastes and preferences is a powerful selling point, and manufacturers are exploring how to make these presses as adaptable as possible.

As the world becomes more connected, the importance of international compatibility cannot be overstated. Dual voltage sandwich presses are already designed to meet this need, but the future may bring even more innovative solutions. Think of a press that not only operates on two voltage standards but also includes a feature that automatically adjusts to the local electrical setting. This kind of technology would eliminate the need for additional transformers or adapters, making the appliance truly universal.

The rise of e-commerce has also influenced the appliance market. Consumers are now accustomed to browsing and purchasing products online, and dual voltage sandwich presses are no different. The future may see more manufacturers offering a digital experience that includes interactive guides, recipe suggestions, and even virtual demonstrations of the appliance’s features. This kind of engagement can help build brand loyalty and drive sales.

The impact of social media and influencer marketing cannot be ignored. As more people turn to platforms like Instagram and YouTube for cooking inspiration, the demand for visually appealing and shareable content is on the rise. Dual voltage sandwich presses could benefit from this trend by creating marketing campaigns that encourage users to share their culinary creations online. This not only promotes the product but also fosters a community of enthusiasts who are passionate about sandwiches and cooking.

Lastly, the future of dual voltage sandwich presses will be shaped by the commitment to quality and customer service. As consumers become more discerning, they expect appliances that not only perform well but also offer excellent support. This means investing in robust warranties, easy-to-access customer service, and a commitment to product longevity. By focusing on these aspects, manufacturers can ensure that their dual voltage sandwich presses are not just a passing trend but a staple in kitchens around the world.

In conclusion, the future of dual voltage sandwich presses is bright, with a multitude of opportunities for innovation and growth. From smart technology and energy efficiency to health-conscious designs and global compatibility, these appliances are poised to evolve in exciting ways. As consumers continue to seek convenience, customization, and quality, the dual voltage sandwich press market is likely to thrive, offering a variety of options that cater to the diverse needs and preferences of modern cooks.